Preparation method for aluminum-graphene metallic composite

A metal composite material and graphene technology, applied in the field of functional materials, can solve problems such as difficulty in preparing graphene composite materials, and achieve the effects of low cost, simple preparation method and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

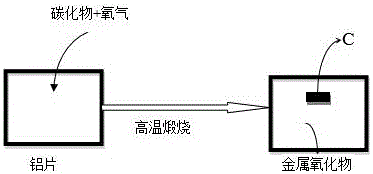

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of basic electrolyte.

[0022] Add 0.5g of aluminum trifluoride to NaCl-CsCl, after mixing thoroughly, add 0.1g of tungsten carbide.

[0023] (2) Growth of aluminum-graphene.

[0024] Put an aluminum sheet with a diameter of 3cm and a height of 1cm containing 0.65% (weight) impurities (0.62% silicon, 0.03% zinc) at the bottom of the alumina crucible, and place the mixture prepared in (1) on top of the aluminum sheet , cover the crucible lid, put it in a vertical heating furnace, heat up to the calcination temperature of 800 ℃ under normal pressure, and the calcination time is 1.5h. After the high temperature calcination is completed, pour the liquid mixture in the crucible into another In an alumina crucible, cool at room temperature for 2 hours. After the molten salt mixture is fully solidified, dissolve it in a sodium chloride solution with a mass fraction of 20%, and obtain a solid mixture after filtration. Slowly shake the solid mixture with tweezer...

Embodiment 2

[0026] According to the preparation method in Example 1, the difference is that the added carbide is 0.1 g titanium carbide, the alkali metal chloride is KCl, the calcination temperature is 750° C., the calcination time is 3 h, and the cooling time is 1.5 h. The hardness, strength and ductility of the prepared aluminum-graphene composite were tested, which were about 1.31 times that of pure aluminum metal materials.

Embodiment 3

[0028] According to the preparation method in Example 1, the difference is that the added carbide is 0.1g silicon carbide, the alkali metal chloride is KCl-AgCl, the calcination temperature is 700°C, the calcination time is 5h, and the cooling time is 2h. The hardness, strength and ductility of the prepared aluminum-graphene composite were tested, which were about 1.42 times that of pure aluminum metal materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com