Method and apparatus for manufacturing a staple fiber based on natural protein fiber, a raw wool based on the staple fiber, a fibrous yarn made of the staple fiber, a non-woven material made of the staple fiber and an item comprising the staple fiber

A protein fiber and non-woven material technology, applied in the direction of short fiber formation, fiber raw material processing, single-component protein rayon, etc., can solve problems such as poor performance, product recyclability or the impact of processing stages, and achieve improved strength performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

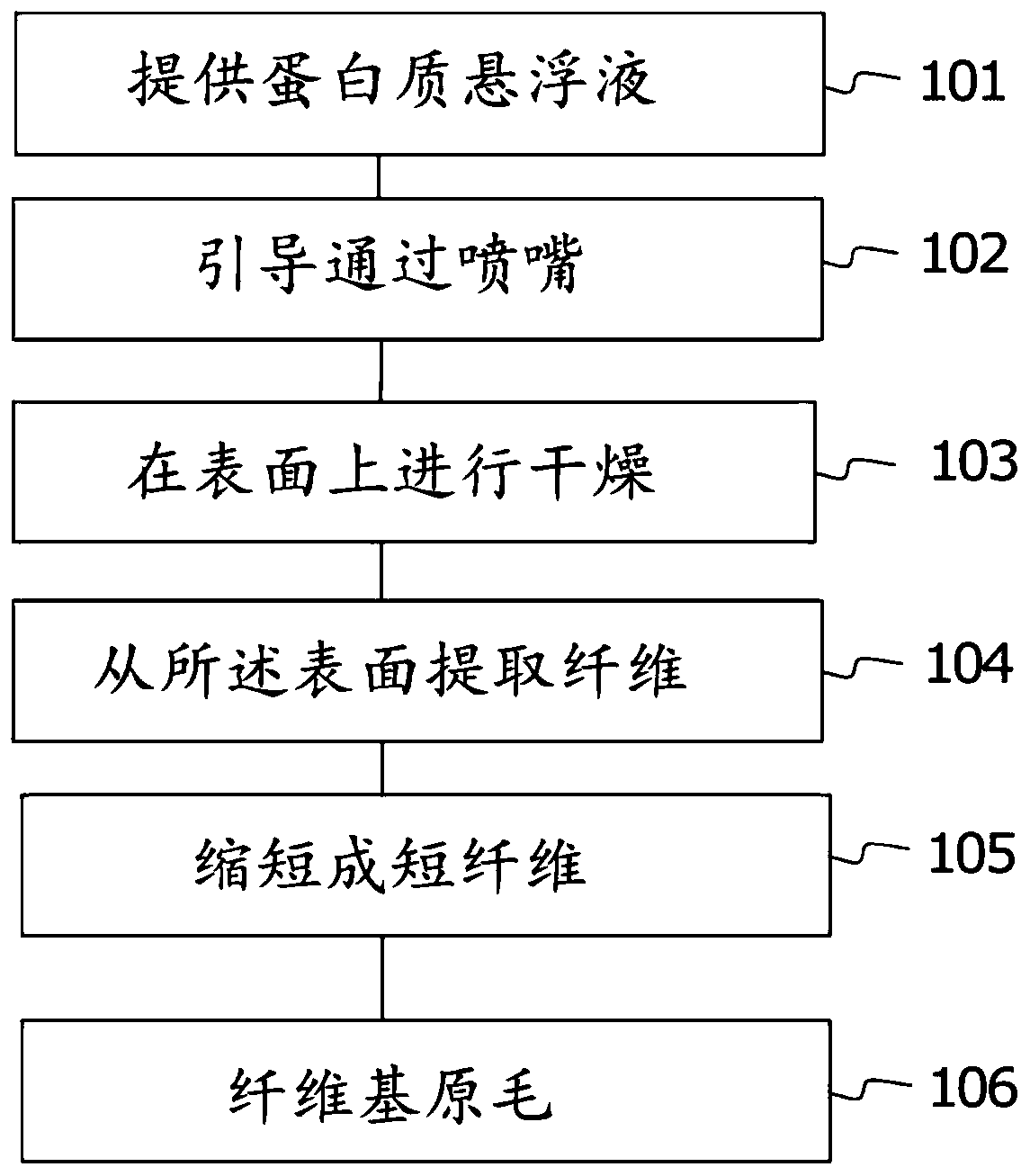

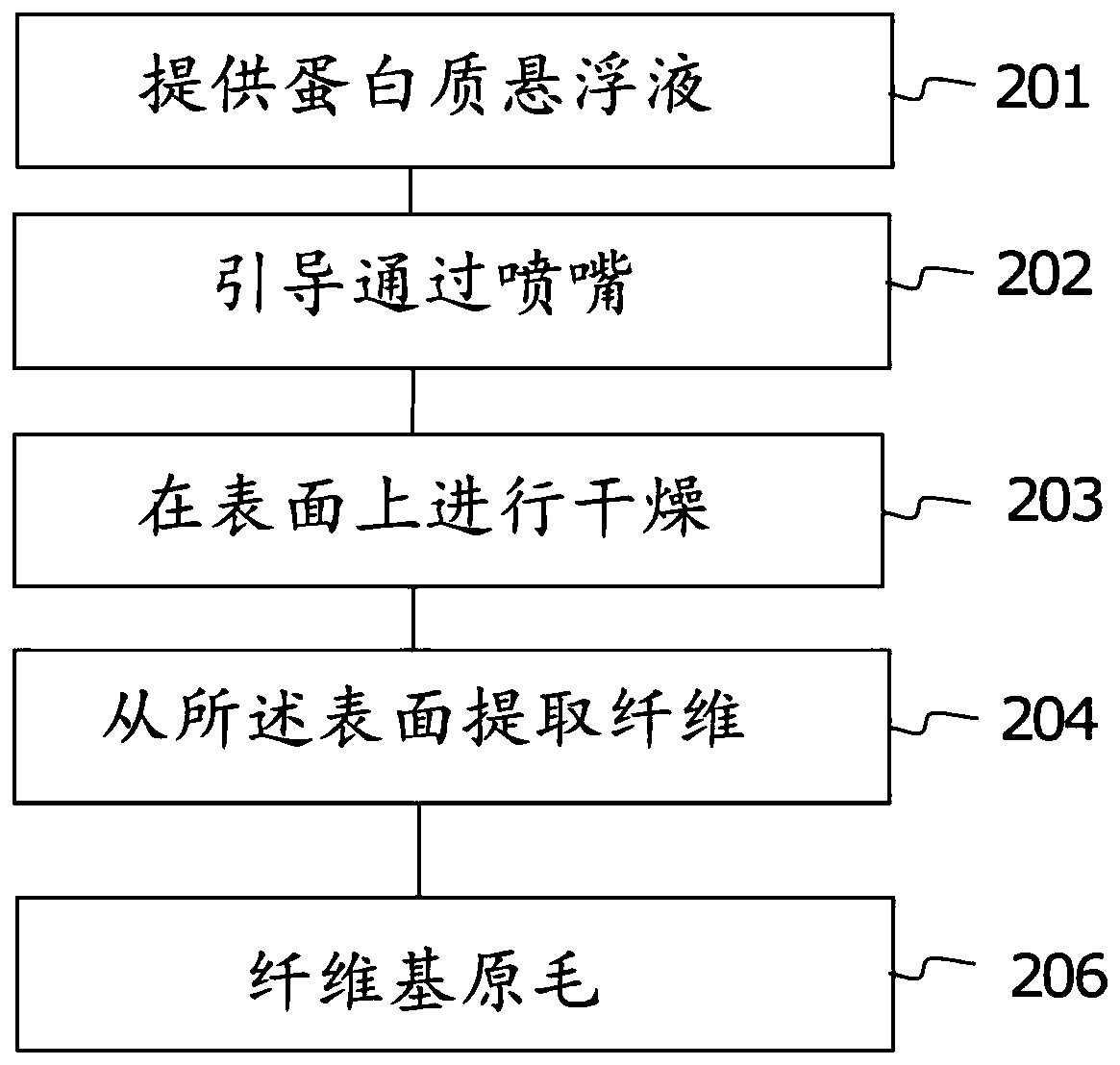

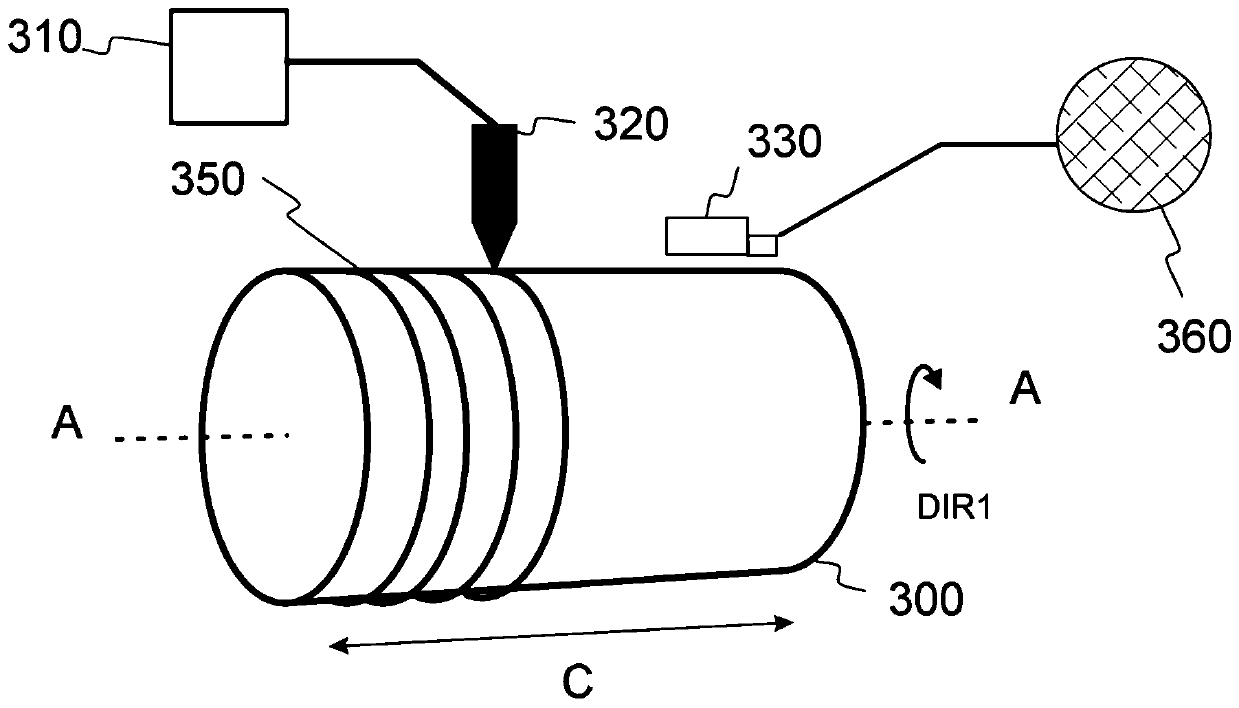

[0106] figure 1 Illustrated is a method for producing natural fiber based raw wool, according to one embodiment. At 101, a protein suspension is provided. The protein suspension comprises an aqueous suspension of mechanically separated protein fibrils. In other words, the protein fibrils themselves were considered natural fibrils. The protein suspension may comprise water, isolated protein fibrils and at least one rheology modifier. The fibrils of the protein suspension may be derived from mechanically shortened protein fibers. In a preferred embodiment of the invention, the protein fibrils are collagen fibrils derived from tanned pelt-based material. Thus, collagen fibrils may be derived, for example, from wetblue hides, i.e., pelts that have been tanned, and where the collagen fibers used as the basis for reconstituted collagen-based fibrils have been tanned according to conventional and well-known methods, (e.g., pretreated by chromium salts).

[0107] At 102, a prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com