Full-thread degradable pure-magnesium bolt

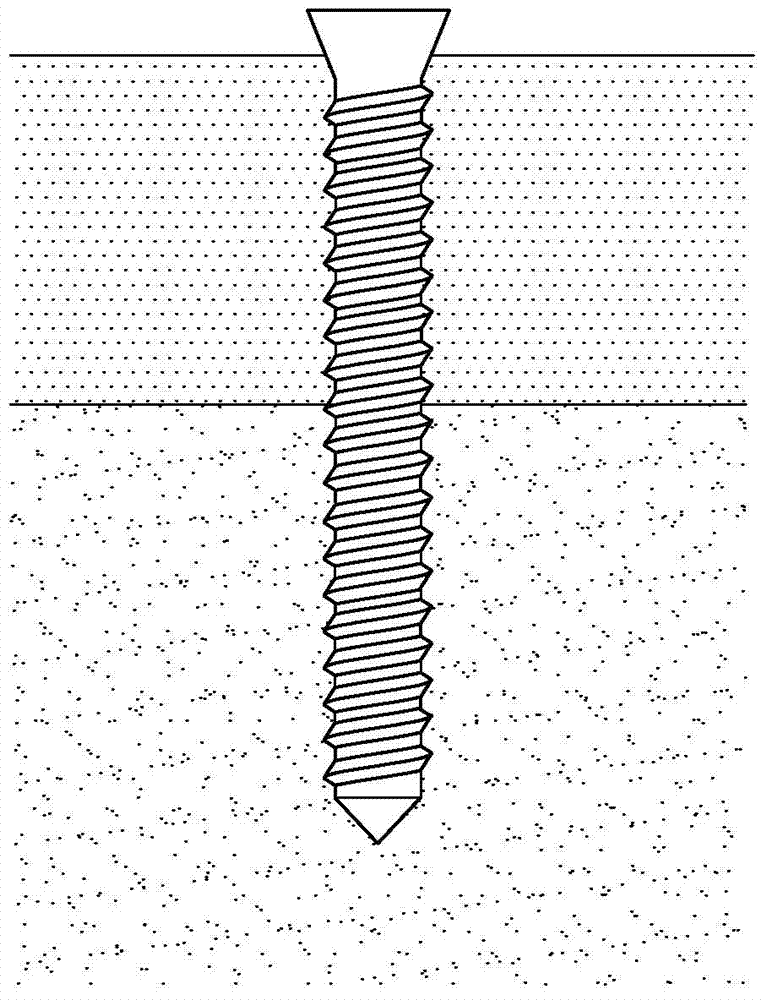

A full-thread and screw technology, applied in the field of medical implants, can solve the problems of easy deformation and fracture, insufficient post-pressurization force, insufficient holding force of magnesium screws, etc., to reduce deformation and fracture, low cost, good holding and fixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

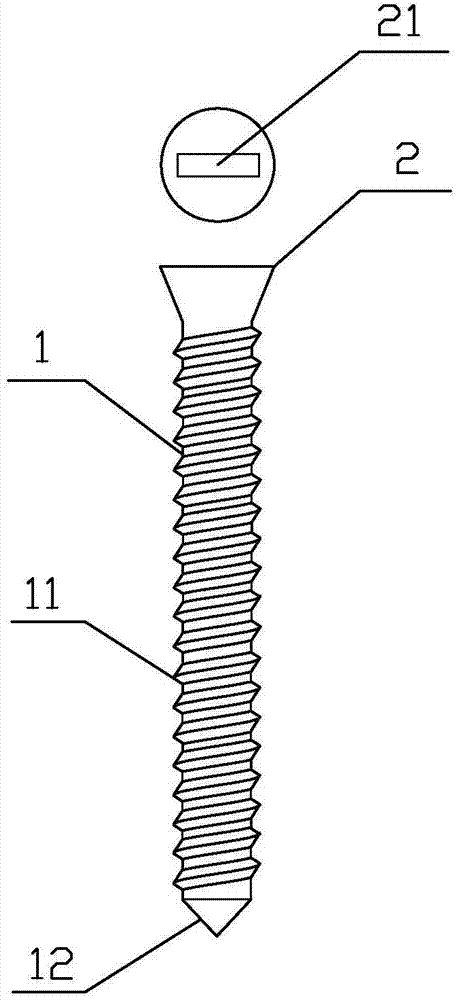

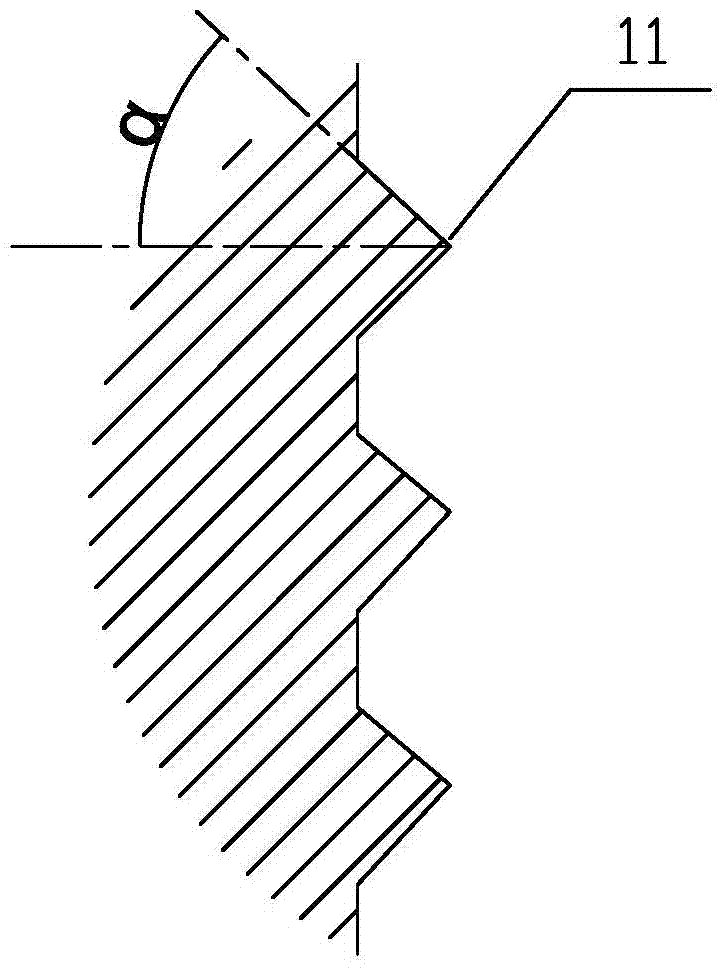

[0034] A pre-thread degradable pure magnesium screw, the length of the body 1 is 25mm, the angle between the surface connecting the nut 2 and the body 1 and the center line of the body is 22°, the thickness of the nut 2 is 3mm, and the thread width is 0.5mm , the thread pitch is 0.55mm, the thread depth is 1 / 10 of the body diameter, the thread lead angle is 5°, the flank angle α is 50°, the top angle of the screw front end 12 is 120°, and the length of the screw front end 12 is 1.3mm.

[0035] The pure magnesium composition used in this embodiment is: Mg: 99.99%; Al: 0.002%; Si: 0.0007%; Ca: 0.0003%; Ti: 0.0001%; Mn: 0.002%; Cu: 0.0002%; Zn: 0.0028%; Pb: 0.0008%.

Embodiment 2

[0037] A front-thread degradable pure magnesium screw, the length of the body 1 is 28mm, the angle between the surface connecting the nut 2 and the body 1 and the center line of the body is 26°, the thickness of the nut 2 is 3.5mm, and the thread width is 0.6 mm, the thread pitch is 0.65mm, the thread depth is 1 / 7 of the body diameter, the thread lead angle is 10°, the flank angle α is 40°, the top angle of the screw front end 12 is 90°, and the length of the screw front end 12 is 1.4mm .

[0038] The pure magnesium composition used in this embodiment is: Mg: 99.99%; Al: 0.002%; Si: 0.001%; Ca: 0.00005%; Ti: 0.00005%; Mn: 0.002%; Cu: 0.0002%; Zn: 0.0028%; Pb: 0.0008%.

Embodiment 3

[0040]A pre-thread degradable pure magnesium screw, the length of the body 1 is 30mm, the angle between the surface connecting the nut 2 and the body 1 and the center line of the body is 30°, the thickness of the nut 2 is 4mm, and the thread width is 0.7mm , the thread pitch is 0.75mm, the thread depth is 1 / 5 of the body diameter, the thread lead angle is 20°, the flank angle α is 30°, the top angle of the screw front end 12 is 30°, and the length of the screw front end 12 is 1.5mm.

[0041] The pure magnesium composition used in this embodiment is: Mg: 99.99%; Al: 0.002%; Si: 0.00008%; Ca: 0.001%; Ti: 0.0001%; Mn: 0.002%; Cu: 0.0002%; Zn: 0.0028%; Pb: 0.0008%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com