Preparation method and application method of granular activated carbon for xylose decoloring

A technology of granular activated carbon and powdered activated carbon, applied in the production of sugar, chemical instruments and methods, applications, etc., can solve the problems of no decolorization, long production cycle, harsh working environment, etc., and achieve easy adjustment and processing, saving production Cost, effect of improving production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

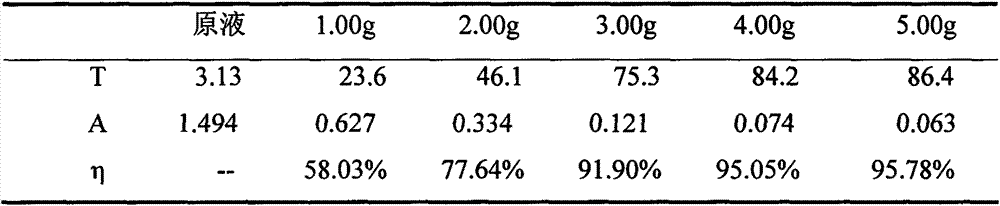

Image

Examples

Embodiment 1

[0024] The present embodiment proposes a kind of preparation method of granular activated carbon for xylose decolorization, comprising the following steps:

[0025] (A) material preparation: the phosphoric acid method powdery activated carbon, acrylic acid emulsion, and water with wood chips as raw materials are weighed according to the weight ratio of acrylic acid emulsion: phosphoric acid method powdery activated carbon: water=0.375:1:1, and the water content of the acrylic acid emulsion 34%.

[0026] (B) Mixing: Mix the above-mentioned raw materials and fully stir them, and smash the particles formed in the stirring process at the same time to achieve uniform mixing;

[0027] (C) Particle molding: Extrude the uniformly mixed raw materials through a granulator at a constant temperature of 90°C to make particles with a particle size of 3mm, and gently roll and cool the formed granular activated carbon to 40~50℃;

[0028] (D) Drying: place the cooled granular activated carbon ...

Embodiment 2

[0036] The present embodiment proposes a kind of preparation method of granular activated carbon for xylose decolorization, comprising the following steps:

[0037] (A) material preparation: take sawdust as raw material phosphoric acid method powdery activated carbon, acrylic acid emulsion, water by weight ratio of acrylic acid emulsion: phosphoric acid method powdery activated carbon: water=0.38:1:1, and the water content of said acrylic acid emulsion 33%.

[0038] (B) Mixing: Mix the above-mentioned raw materials and fully stir them, and smash the particles formed in the stirring process at the same time to achieve uniform mixing;

[0039] (C) Particle molding: Extrude the uniformly mixed raw materials through a granulator at a constant temperature of 90°C to make particles with a particle size of 4mm, and gently roll and cool the formed granular activated carbon to 40~50℃;

[0040] (D) drying: place the cooled granular activated carbon at a temperature of 150° C. and dry ...

Embodiment 3

[0048] The present embodiment proposes a kind of preparation method of granular activated carbon for xylose decolorization, comprising the following steps:

[0049] (A) material preparation: the phosphoric acid method powdery activated carbon, acrylic acid emulsion, and water with wood chips as raw materials are weighed according to the weight ratio of acrylic acid emulsion: phosphoric acid method powdery activated carbon: water=0.385:1:1, and the water content of the acrylic acid emulsion 32.5%.

[0050] (B) Mixing: Mix the above-mentioned raw materials and fully stir them, and smash the particles formed in the stirring process at the same time to achieve uniform mixing;

[0051] (C) Particle forming: Extrude the uniformly mixed raw materials through a granulator at a constant temperature of 90°C to make particles with a particle size of 4.5mm, and gently roll and cool the formed granular activated carbon through a rotating cooling drum to 40~50℃;

[0052] (D) Drying: place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com