Method for producing mass material of compactness toughening veneer

A technology of laminated veneer lumber and compactness, which is applied in the jointing of wooden veneers, wood treatment, impregnated wood, etc., can solve the problems of small processing value-added range and limited use range, and achieve strength improvement, anti-corrosion and insect-proof surface The effect of processing cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

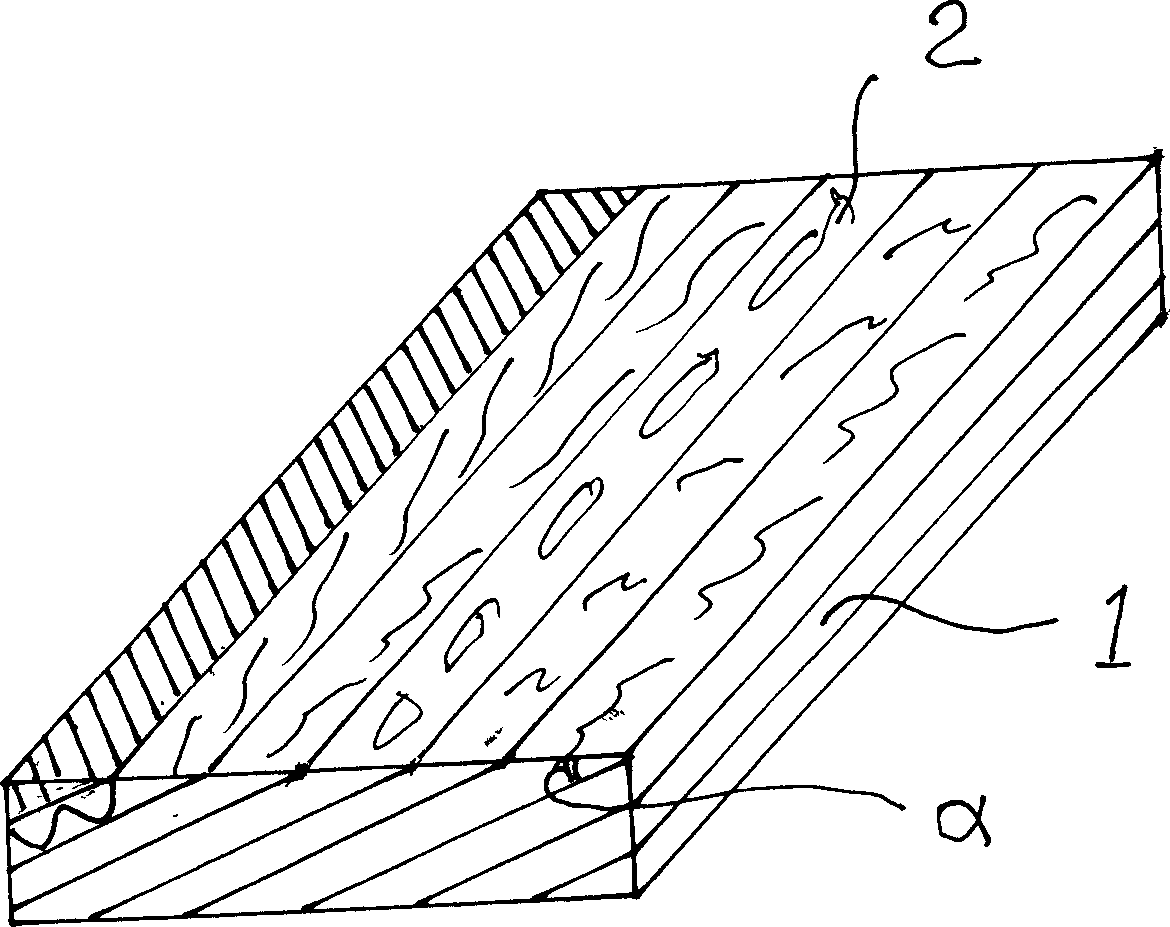

[0024] The production method and structure of the densely reinforced laminated veneer lumber provided by the present invention with a wood-patterned surface will be further described below in conjunction with the accompanying drawings.

[0025] The production process steps of compactness reinforced laminated veneer lumber are:

[0026] The first step: processing log wood into veneer sheets;

[0027] Step 2: Remove water from the above-mentioned veneer sheets by cooling or drying and other methods to make them dry;

[0028] Step 3: Put the dried veneer sheet into the container, seal the lid and evacuate to 0.5Mpa, and extract the air in the capillary pores of the veneer sheet to facilitate the soaking of glue (the glue can be used as Adhesives for ordinary laminated veneer lumber, or other curable glues);

[0029] Step 4: Inject the glue solution into the vacuumized container to soak the inside of the veneer sheet;

[0030] Step 5: Take out the soaked veneer sheet, put it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com