Composite material for manufacturing mildew-proofing rot-proofing door plate and preparation method thereof

A technology of composite materials and door panels, which is applied in the field of composite materials, can solve the problems of unsatisfactory high-performance materials, moldy door panels, and easy corrosion, and achieve high performance, prolong life, and anti-mildew and anti-corrosion properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

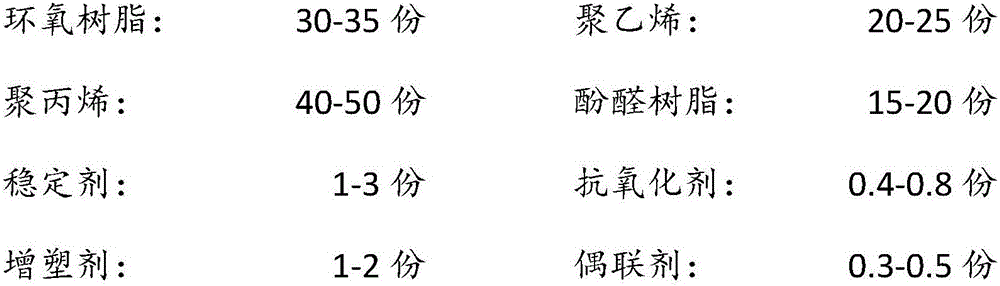

[0027] In parts by weight, the composition of a composite material for making mildew-proof and anti-corrosion door panels and a preparation method thereof of the present embodiment is as follows:

[0028]

Embodiment 2

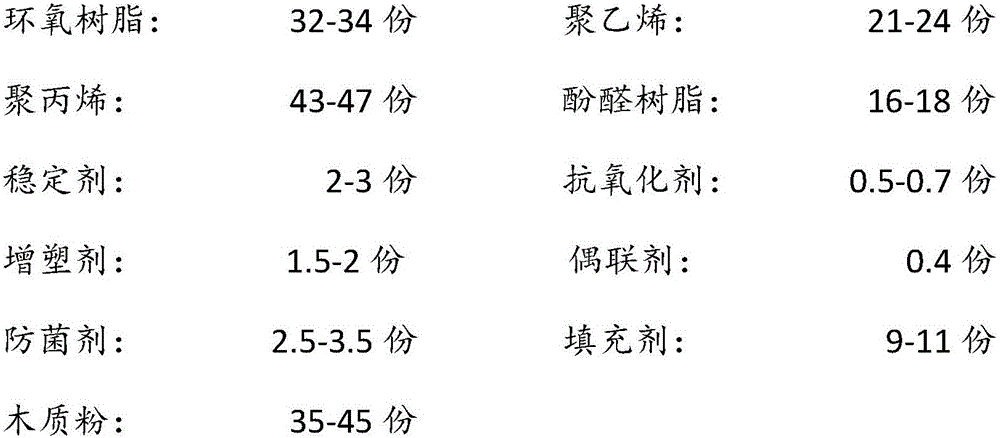

[0030] In parts by weight, the composition of a composite material for making mildew-proof and anti-corrosion door panels and a preparation method thereof of the present embodiment is as follows:

[0031]

Embodiment 3

[0033] In parts by weight, the composition of a composite material for making mildew-proof and anti-corrosion door panels and a preparation method thereof of the present embodiment is as follows:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com