Pre-treating technique for composite metal plastic pipe

A steel-plastic composite pipe, pretreatment technology, applied in the direction of pretreatment surface, metal material coating process, device for coating liquid on the surface, etc., to achieve the effect of improving adhesion, simple and convenient operation, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with specific examples, but the specific examples do not limit the present invention in any way.

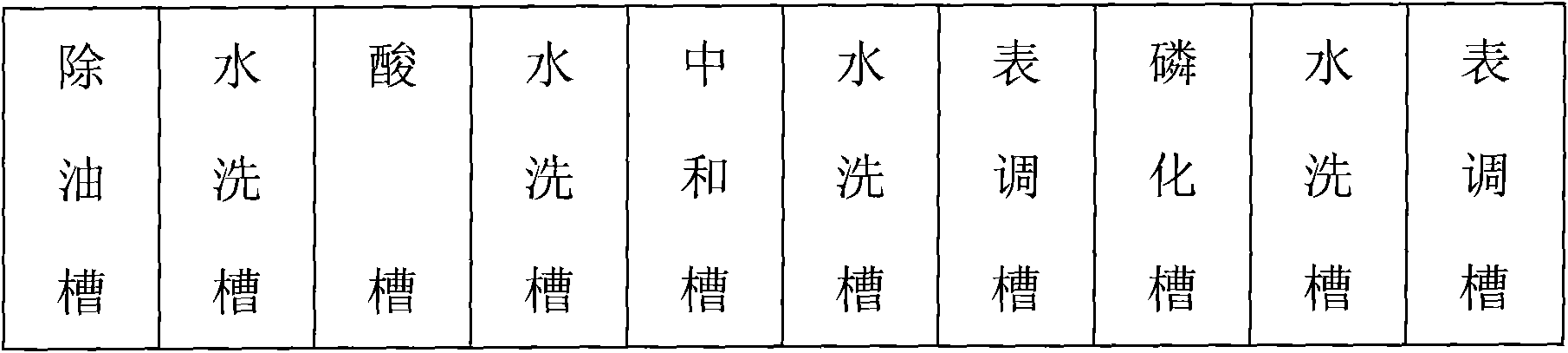

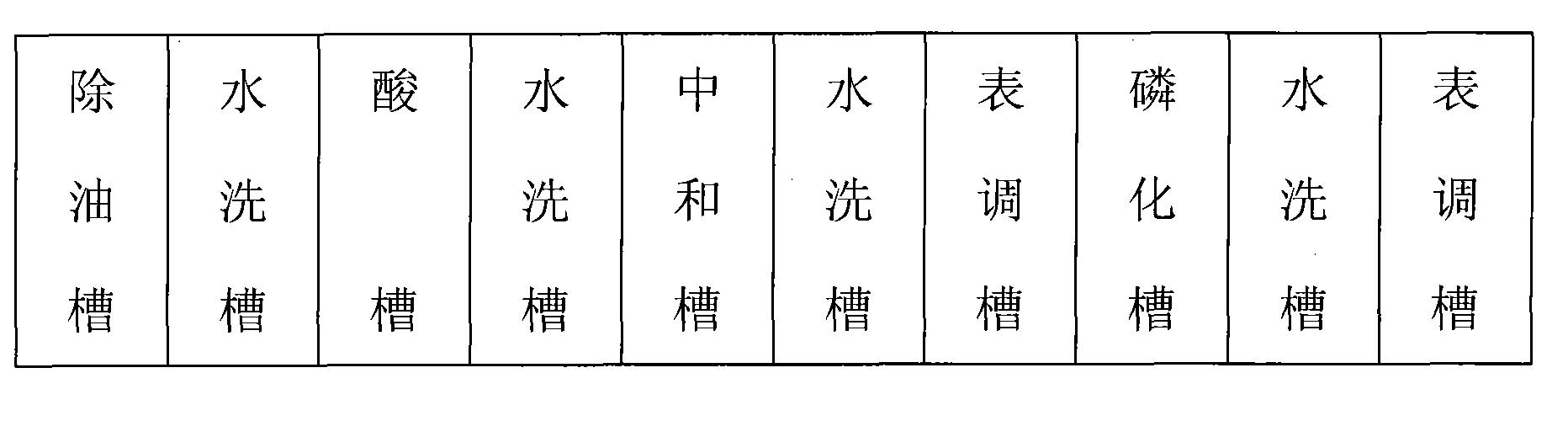

[0051] The steel-plastic composite pipe pretreatment process of the present invention follows the process of "grease removal→water washing→pickling→water washing→neutralization→water washing→surface conditioning→phosphating→water washing→surface conditioning→drying". The steel pipes are placed in various treatment tanks in turn, and after being treated for a period of time, they are taken out and entered into the next treatment tank, so as to complete the goals of degreasing, rust removal and phosphating in turn. The distribution of the tank body of the present invention is as follows figure 1 shown.

[0052] like figure 1 As shown, the degreasing tank, water washing tank, acid tank, water washing tank, neutralization tank, water washing tank, surface conditioning tank, phosphating tank, water washing ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com