Environment-friendly water replacing antirust oil

A technology of anti-rust oil and environmentally friendly water, applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as water stains cannot be effectively removed, workpiece rust, etc., achieve excellent rust resistance and water replacement, and reduce procurement costs. , good anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

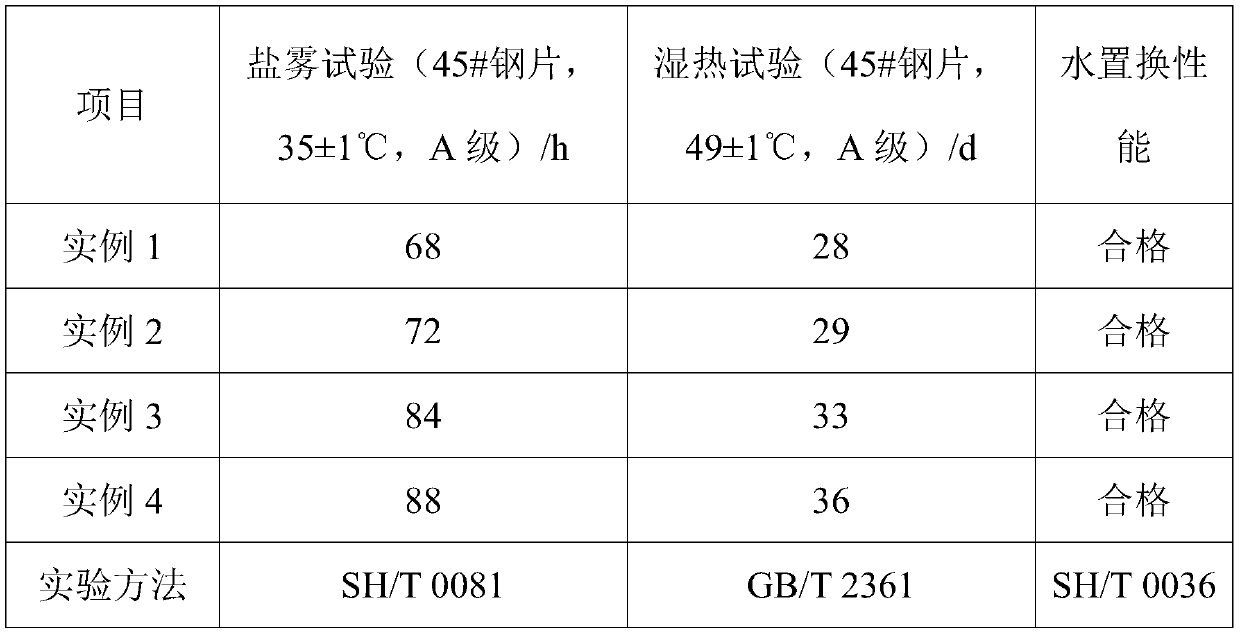

Examples

Embodiment 1

[0021] The sulfonic acid amine of this example was synthesized according to the following method:

[0022] Add sodium petroleum sulfonate and tetradecylamine into the reaction kettle at a molar ratio of 1:1.5, draw out the air from the reaction kettle until the pressure is less than or equal to 100Pa, and fill it with nitrogen until the pressure is 3MPa;

[0023] After heating to 115° C., stirring at constant temperature for 120 min, extracting nitrogen gas until the air pressure is less than 300 Pa, heating to 135° C., stirring at constant temperature for 70 min, and distilling out excess tetradecyl amine under reduced pressure; the sulfonic acid amine can be prepared after cooling.

[0024] An environmentally-friendly water-displacement anti-rust oil composition is composed of the following components in parts by mass: 84 parts of D100, 8 parts of sulfonamides, 5 parts of oleic acid, and 3 parts of basic aluminum stearate.

Embodiment 2

[0026] The sulfonic acid amine of this example was synthesized according to the following method:

[0027] Add sodium petroleum sulfonate and hexadecylamine into the reactor at a molar ratio of 1:1.7, draw out the air from the reactor until the pressure is less than or equal to 100Pa, and fill with nitrogen until the pressure is 3.2MPa;

[0028] After heating to 110°C, stirring at constant temperature for 140min, extracting nitrogen until the pressure is less than 300Pa, heating to 140°C, stirring at constant temperature for 80min, and distilling excess hexadecylamine under reduced pressure; the sulfonic acid amine can be prepared after cooling.

[0029] An environmentally friendly water-replacement type anti-rust oil composition is composed of the following components in parts by mass: 86 parts of D80, 8 parts of sulfonamides, 2 parts of fatty acid polyvinyl ether, and 4 parts of basic aluminum stearate.

Embodiment 3

[0031] The sulfonic acid amine of this example was synthesized according to the following method:

[0032] Add sodium petroleum sulfonate and heptadecylamine into the reaction kettle at a molar ratio of 1:2.0, draw out the air from the reaction kettle until the pressure is less than or equal to 100 Pa, and fill with nitrogen until the pressure is 3.5 MPa;

[0033] After heating to 120°C, stirring at constant temperature for 120min, extracting nitrogen until the pressure is less than 300Pa, heating to 130°C, stirring at constant temperature for 60min, and distilling excess heptadecylamine under reduced pressure; the sulfonic acid amine can be prepared after cooling.

[0034] An environmentally-friendly water-displacement anti-rust oil composition is composed of the following components in parts by mass: 48 parts of D60, 37 parts of D70, 10 parts of sulfonamides, 3 parts of oleic acid, and 2 parts of basic aluminum stearate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com