Hydraulic fracturing ground stress testing device with equal diameter design

A technology for testing equipment and in-situ stress, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of testing equipment stuck, unable to be retracted to the ground, and testing equipment falling into holes, etc., to achieve high overall rigidity , Eliminate water leakage and pressure leakage and test failure, and the effect of not being easy to bend and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

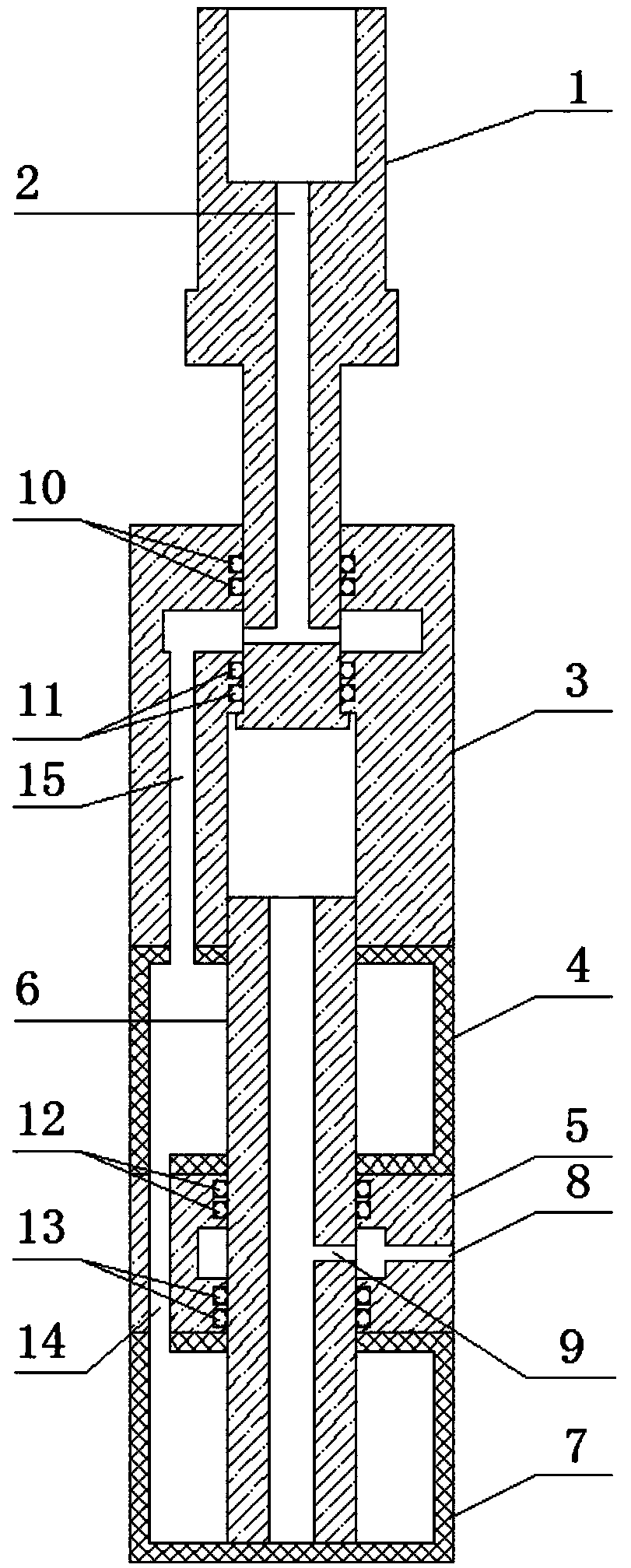

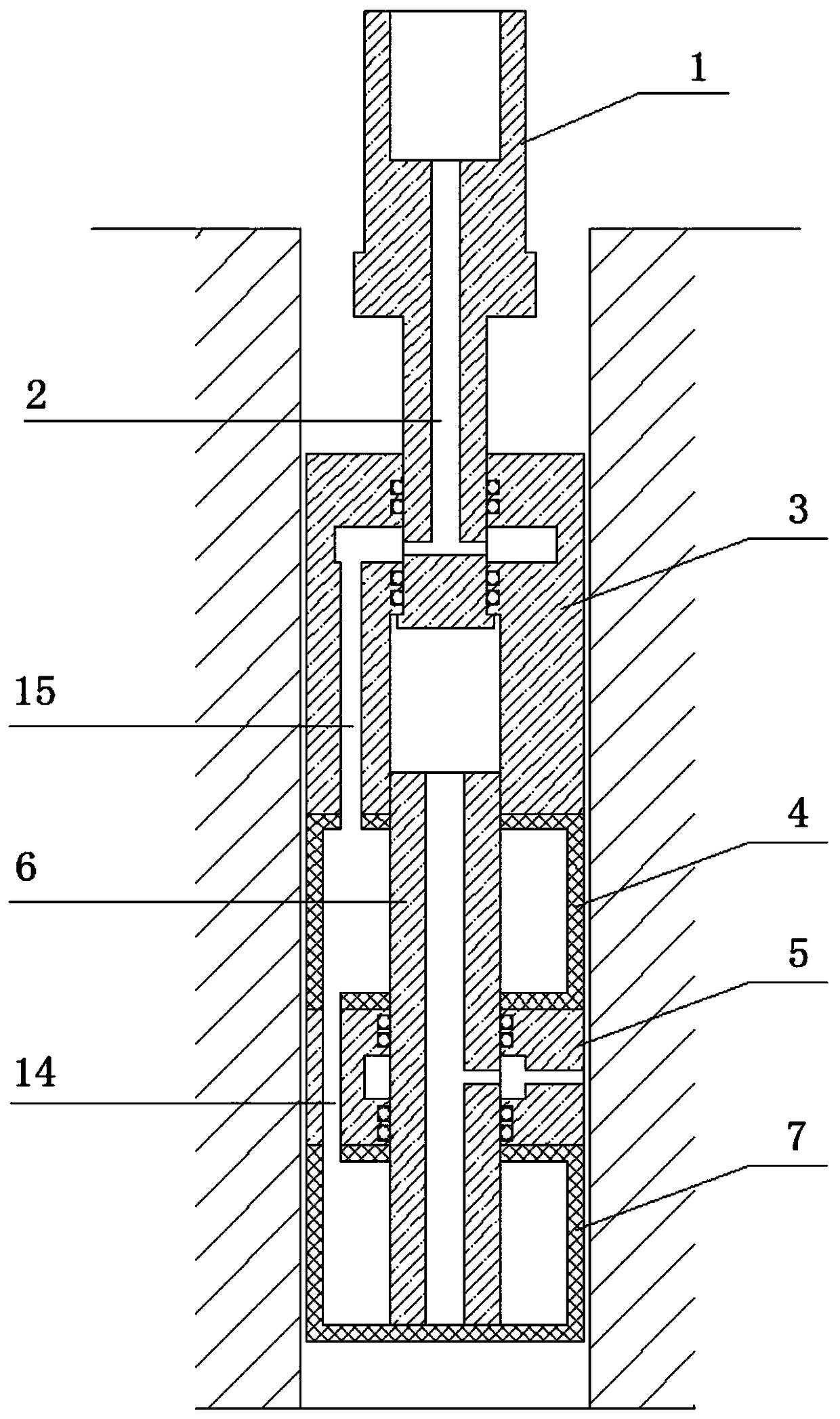

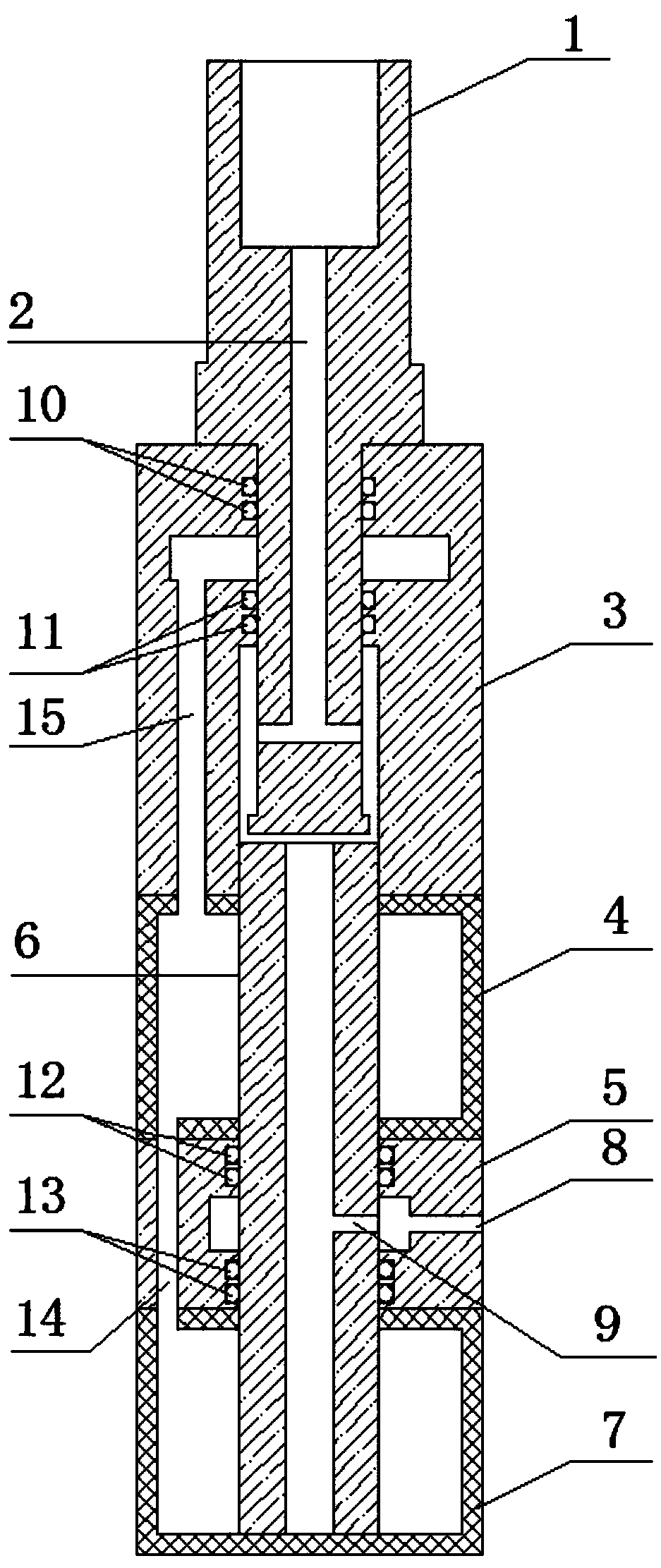

[0024] Such as Figure 1 to Figure 4 As shown, the present invention provides a hydraulic fracturing ground stress testing device with an equal diameter design, including a sliding valve column 1, a valve seat 3, an upper packer 4, a cracking flower tube 5, a central rod 6 and a lower Packer 7, the sliding spool 1 is installed in the valve seat 3 and protrudes from the upper end of the valve seat 3 to connect to the lower end of the drill pipe (not shown in the figure), and the spool water hole 2 is opened in the sliding spool 1 , the water hole 2 of the spool communicates with the inner hole of the drill pipe 16, the central rod 6 is connected to the lower end of the valve seat 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com