Power generation method using biomass

A biomass power generation and biomass technology, applied in the direction of biofuels, educts, engine components, etc., can solve the problems of large demand for raw materials, environmental pollution, etc., and achieve high gas calorific value, high flexibility, and high production intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

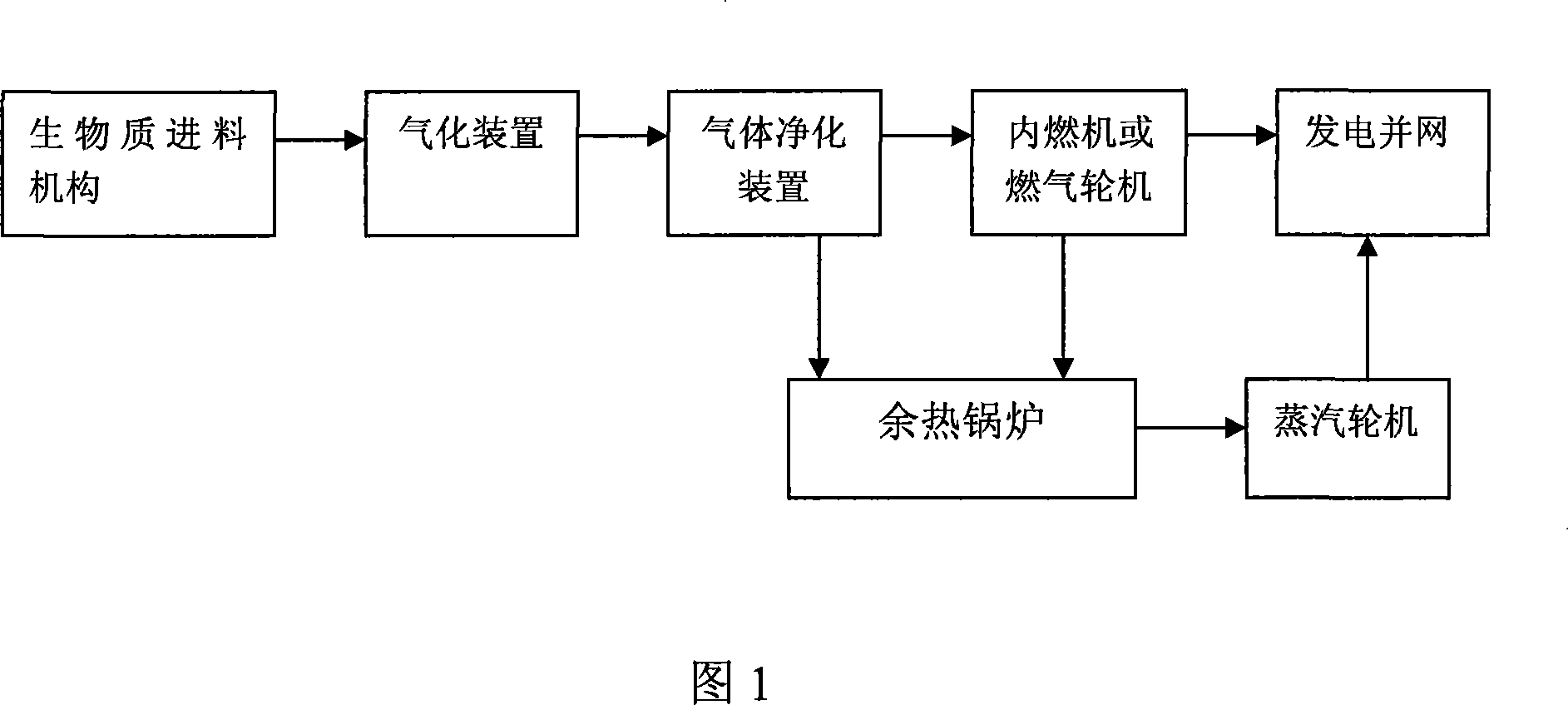

[0016] As shown in Figure 1, using gasification technology, agricultural and forestry wastes, including waste straw, sawdust, straw, rice husk, bagasse, etc., are converted into combustible gases close to coal gas through gasification devices. The main components of these combustible gases are CO, h 2 、CH 4 , CO 2 etc., calorific value is 1250kcal / m 3 Left and right, containing a small amount of tar at the same time, these combustible gases are removed from dust and tar by the gas purification device, and then sent to the gas internal combustion engine or gas turbine for power generation. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com