Frequency self-adaptive circuit of parallel resonant induction heating power supply

An induction heating power supply and frequency self-adaptive technology, applied in the electrical field, can solve problems such as system digitization, narrow start-up frequency range, and low start-up success rate, and achieve the effects of increased active power, good load adaptability, and reliable start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in conjunction with accompanying drawing and specific embodiment;

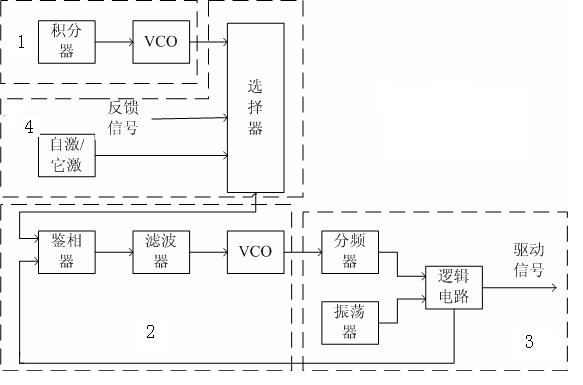

[0022] Such as figure 1 As shown, a parallel resonant induction heating power supply frequency adaptive circuit, the parallel resonant induction heating power supply frequency adaptive circuit includes a frequency sweep start circuit 1, a frequency tracking circuit 2, an overlapping area processing circuit 3 and a signal gating circuit 4 ; When the power is started, the frequency sweeping start circuit 1 outputs a frequency sweeping drive signal continuously changing to drive the inverter. The signal directly drives the inverter through the signal gating circuit 4. When the amplitude of the feedback signal reaches the preset threshold value, it means that the current frequency is close to the load resonance frequency. At this time, the level of the self-excited / other-excited signal generated by the comparison circuit changes, and the control system is controlled by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com