Asphalt rubber material for producing SBS elastomer modified asphalt waterproof roll material as well as preparation method and application thereof

A technology of asphalt waterproof membrane and asphalt glue, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of low-temperature flexibility of waterproof membrane, high-temperature resistance, cohesion and waterproof performance, etc., so as to achieve good quality control , Reduce production costs, improve cohesion and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

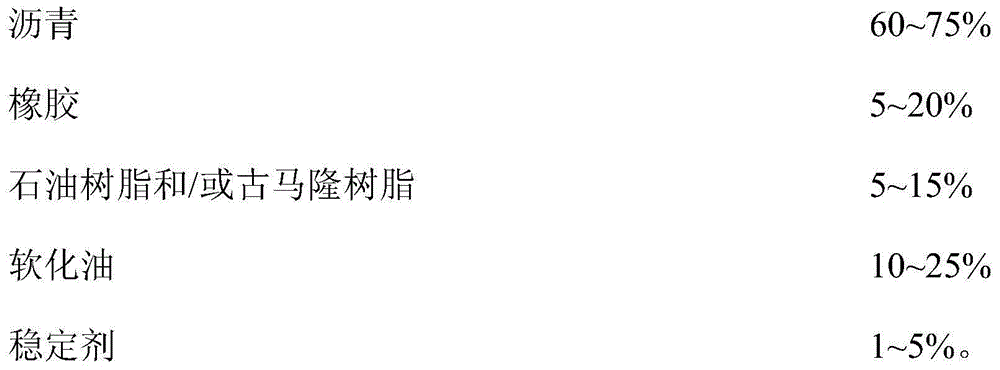

[0038] A bituminous compound for producing SBS elastomer-modified asphalt waterproofing membrane, which is prepared from the following raw materials according to the mass percentage of each raw material in the asphalt compound:

[0039]

[0040]

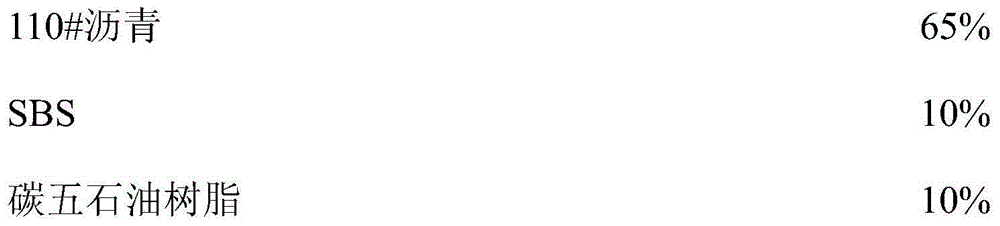

[0041] The preparation method of the asphalt rubber compound: compound 110# asphalt, SBS, C5 petroleum resin and stabilizer according to the above formula, then heat up to 185°C to 200°C for 4 hours, and stir during the reaction to make Mix all components evenly, then lower the temperature to 165°C, add rubber oil and stir for 30 minutes at a stirring speed of 200r / min to form asphalt rubber.

[0042] The asphalt compound used in the SBS elastomer modified asphalt waterproofing membrane prepared in Example 1 was compared with 110# asphalt, and the results are shown in Table 1. Among them, the softening point, ductility and penetration are tested according to the following methods:

[0043] Softening point test method: The soft...

Embodiment 2

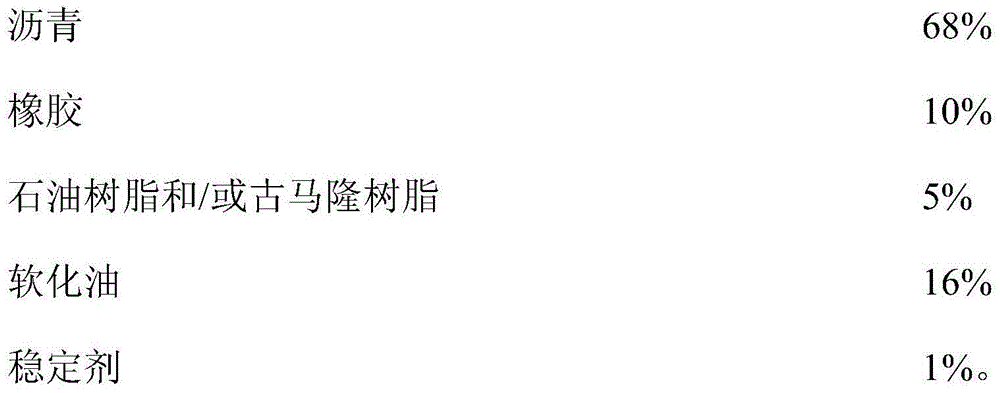

[0050] A bituminous compound for producing SBS elastomer-modified asphalt waterproofing membrane, which is prepared from the following raw materials according to the mass percentage of each raw material in the asphalt compound:

[0051]

[0052] The preparation method of the asphalt rubber compound: compound 70# asphalt, SBRS, coumarone resin and stabilizer according to the above formula, then heat up to 185°C-200°C for 5 hours, and stir during the reaction, so that Mix all components evenly, then lower the temperature to 165°C, add aromatic oil and stir for 30 minutes at a stirring speed of 200r / min to form an asphalt compound.

[0053] According to the detection method of softening point, ductility and penetration described in Example 1, the bituminous compound used for SBS elastomer modified bitumen waterproofing membrane prepared in Example 2 is compared with 70# bitumen in performance , the results are shown in Table 2:

[0054] Table 2

[0055] physical pro...

Embodiment 3

[0057] A bituminous compound for producing SBS elastomer-modified asphalt waterproofing membrane, which is prepared from the following raw materials according to the mass percentage of each raw material in the asphalt compound:

[0058]

[0059] The preparation method of the asphalt rubber compound: compound 100# asphalt, SBR, C9 petroleum resin and stabilizer according to the above formula, then raise the temperature to 185°C-200°C for 4.5h, and stir during the reaction. Mix all components evenly, then lower the temperature to 165°C, add base oil and stir for 30 minutes at a stirring speed of 200r / min to form asphalt rubber.

[0060] According to the detection method of softening point, ductility and penetration described in Example 1, the bituminous compound used for SBS elastomer modified bitumen waterproofing membrane prepared in Example 3 is compared with 100# bitumen in performance , the results are shown in Table 3:

[0061] table 3

[0062] physical prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com