Preparation method of modified vinylidene fluoride polymer powder

A technology of vinylidene fluoride and polymer, which is applied in the field of preparation of modified vinylidene fluoride polymer powder, and can solve problems such as poor adhesion, powder dropping, and poor binding force of binders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

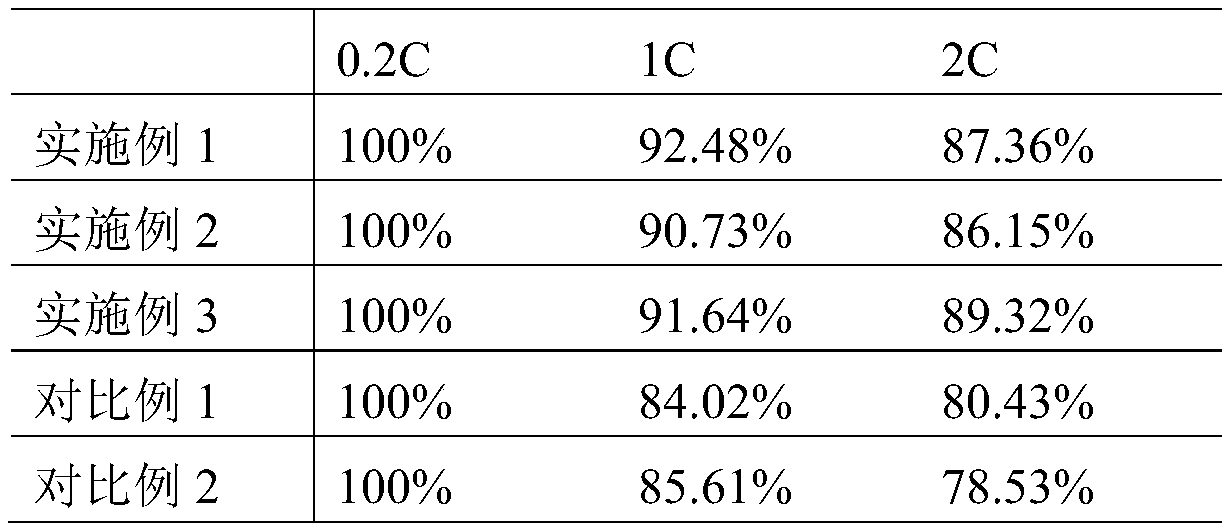

Examples

Embodiment 1

[0078] (1) Preparation of modified PVDF powder precursor

[0079] ① Mix 20 parts of PVDF powder, 0.2 part of acrylic acid, 0.4 part of methacrylic acid, 0.1 part of hydroxyethyl methacrylate, 0.1 part of sodium bisulfite and 80 parts of DI water, stir at room temperature for 0.5 h to obtain mixture A.

[0080] ②Under a nitrogen atmosphere, mix 0.02 parts of acrylamide and 20 parts of DI water in a reactor, stir at 30°C until dissolved, then add the above 80 parts of the premixed emulsion, mix well and heat up to 80°C to obtain mixture B.

[0081] ③ Sodium persulfate was dissolved in DI water to prepare a sodium persulfate solution with a concentration of about 10 wt%.

[0082] ④ Slowly add the above 5 parts of sodium persulfate solution to 100 parts of mixture B, add dropwise while stirring at 70°C and 1000rpm, react for 3 hours, filter, wash, dry and pulverize to obtain the modified PVDF powder precursor, particle size 3μm

[0083] (2) Preparation of modified PVDF powder

...

Embodiment 2

[0089] (1) Preparation of modified PVDF powder precursor

[0090] ①② Same as embodiment 1

[0091] ③ dissolving ammonium persulfate in DI water to prepare an ammonium persulfate solution with a concentration of about 8 wt%.

[0092] ④ Slowly add 10 parts of ammonium persulfate solution above to 100 parts of mixture B, add dropwise while stirring at 80°C and 1000 rpm, react for 3 hours, filter, wash, dry, and pulverize to obtain a modified PVDF powder precursor with a particle size of 3μm

[0093] (2) Preparation of modified PVDF powder

[0094] Disperse 20 parts of the modified PVDF powder precursor in 90 parts of tea polyphenol aqueous solution, the concentration of tea polyphenols is about 3wt%, pH = 8, stir and react at 45°C and 800rpm for 4h, filter, wash, dry and pulverize , to obtain modified PVDF powder with a particle size of 5 μm

[0095] (3) Preparation of composite diaphragm

[0096] ① Mix 30 parts of modified PVDF powder, 8 parts of styrene-butadiene rubber em...

Embodiment 3

[0099] (1) Preparation of modified PVDF-HFP powder precursor

[0100] ① Mix 20 parts of PVDF-HFP powder, 0.2 part of acrylic acid, 0.4 part of methacrylic acid, 0.1 part of hydroxyethyl methacrylate, 0.1 part of sodium bisulfite and 80 parts of DI water, stir at room temperature for 0.5 h to obtain mixture A;

[0101] ②Under a nitrogen atmosphere, mix 0.02 parts of acrylamide and 20 parts of DI water in a reactor, stir at 30°C until dissolved, then add 80 parts of the above-mentioned mixture A, mix well and heat up to 80°C to obtain mixture B.

[0102] ③ Dissolve potassium persulfate in DI water to prepare a 10% potassium persulfate solution.

[0103] ④ Slowly add 10 parts of potassium persulfate solution above to 100 parts of mixture B, add dropwise while stirring at 80°C and 1000 rpm, react for 3 hours, filter, wash, dry, and pulverize to obtain the modified PVDF powder precursor, particle size 4μm

[0104] (2) Preparation of modified PVDF-HFP powder

[0105] Disperse 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com