Drilling pre-formed polycrystalline diamond composite sheet with efficient chip discharge function

A technology of polycrystalline diamond and pre-shaping, which is applied to drill bits, earthwork drilling, drilling equipment, etc. It can solve problems such as tooth chipping, difficult-to-drill formations, and drill bits prone to tooth chipping, so as to reduce grinding heat and improve drilling efficiency. Improve efficiency and reduce the effect of chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

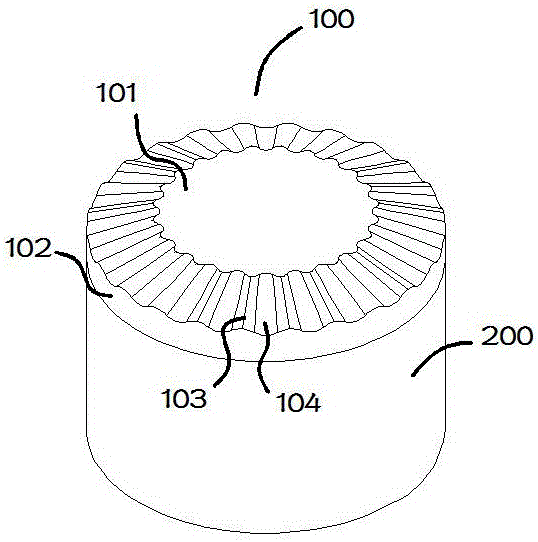

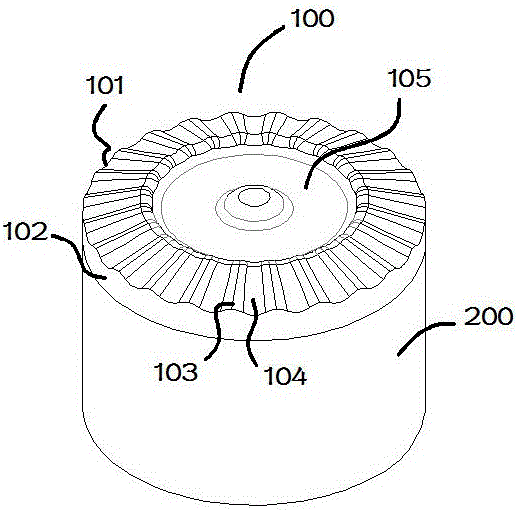

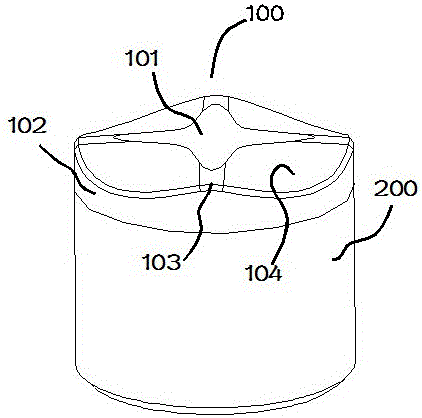

[0032] Such as image 3 and Figure 4 As shown, it is a preformed polycrystalline diamond compact with four teeth of similar structure for efficient chip removal. refer to image 3 As shown, the cutting edge teeth 103 of this four-edge tooth composite sheet have a radial extension length of 1.87mm and a height of 1.23mm, and the angle between it and the outer edge surface 102 is 90°; and the chip removal groove 104 and the cutting edge teeth 103 are at 22 ° are connected in a circular distribution, and the angle between them and the outer edge surface 102 is 112°. The chamfer between the cutting edge teeth 103, the chip removal groove 104 and the outer edge surface 102 is 0.35 mm. refer to Figure 4 As shown, the cutting edge teeth 103 of this four-blade tooth composite sheet have a radial extension length of 1.83mm and a height of 1.23mm, and the angle between it and the outer edge surface 102 is 99.5°; while the chip removal groove 104 and the cutting edge teeth 103 are ...

Embodiment 2

[0034] Such as Figure 5 and Figure 6 As shown, it is a five-blade preformed polycrystalline diamond compact with a similar structure for efficient chip removal. refer to Figure 5 As shown, the cutting edge teeth 103 of this five-blade tooth composite sheet have a radial extension length of 1.91mm and a height of 1.23mm, and the angle between it and the outer edge surface 102 is 90°; ° are connected in a circular distribution, and the angle between them and the outer edge surface 102 is 110°. The chamfer between the cutting edge teeth 103, the chip removal groove 104 and the outer edge surface 102 is 0.35 mm. refer to Figure 6 As shown, the cutting edge teeth 103 of this five-blade tooth composite sheet have a radial extension length of 1.87mm and a height of 1.23mm, and the angle between it and the outer edge surface 102 is 100.1°; while the chip removal groove 104 and the cutting edge teeth 103 are at 35.6 ° are connected in a circular distribution, and the angle bet...

Embodiment 3

[0037] Such as Figure 7 and Figure 8 As shown, it is a high-efficiency chip removal preformed polycrystalline diamond compact with eight teeth of similar structure. refer to Figure 7 As shown, the cutting tooth 103 of the eight-tooth composite sheet has a radial extension length of 1.78 mm and a height of 1.23 mm, and its angle with the outer edge surface 102 is 90°; while the chip removal groove 104 and the cutting tooth 103 are at 23 ° are connected in a circular distribution, and the angle between them and the outer edge surface 102 is 113°. The chamfer between the cutting edge teeth 103, the chip removal groove 104 and the outer edge surface 102 is 0.40 mm. refer to Figure 8 As shown, the cutting tooth 103 of the eight-tooth composite sheet has a radial extension length of 1.76 mm and a height of 1.23 mm, and its angle with the outer edge surface 102 is 99.3°; while the chip removal groove 104 and the cutting tooth 103 are at 32.8 ° are connected in a circular dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

| Extension length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com