Contact-type wire belt grinding machining device

A grinding and contact technology, applied in grinding/polishing safety devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of inability to perform high-speed grinding, strong grinding, machining accuracy effects, length limitations and other problems, to achieve the effect of reducing residual stress, high processing efficiency and reducing grinding heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

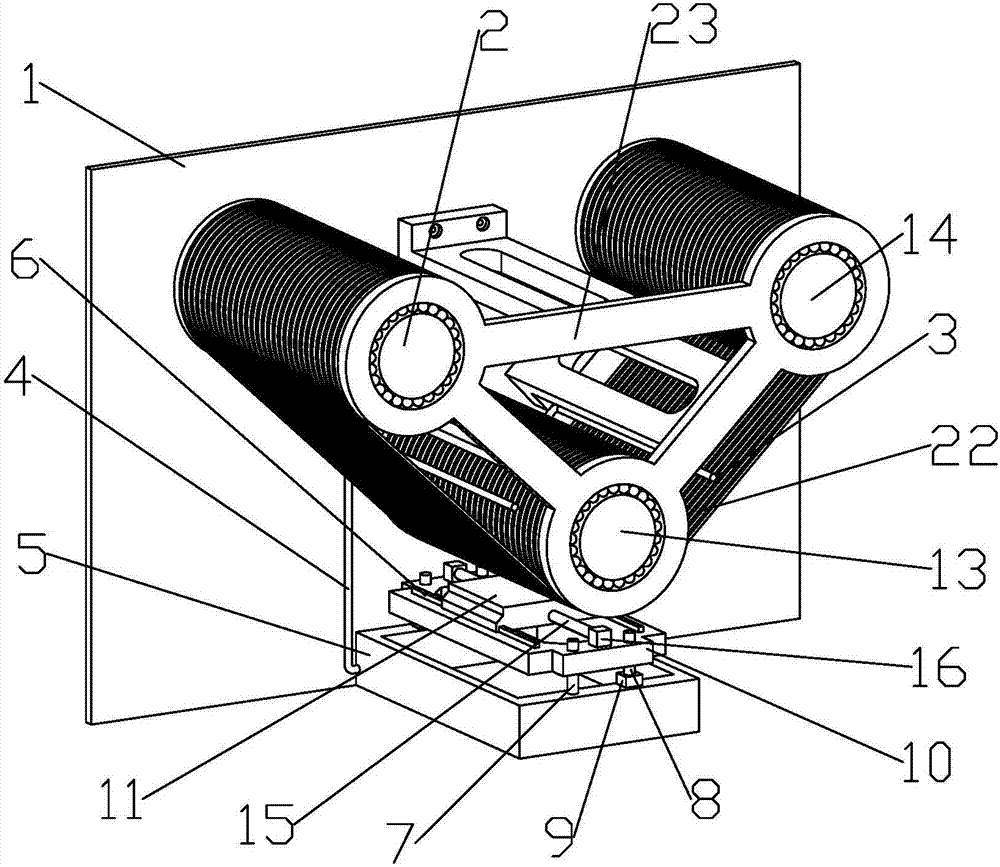

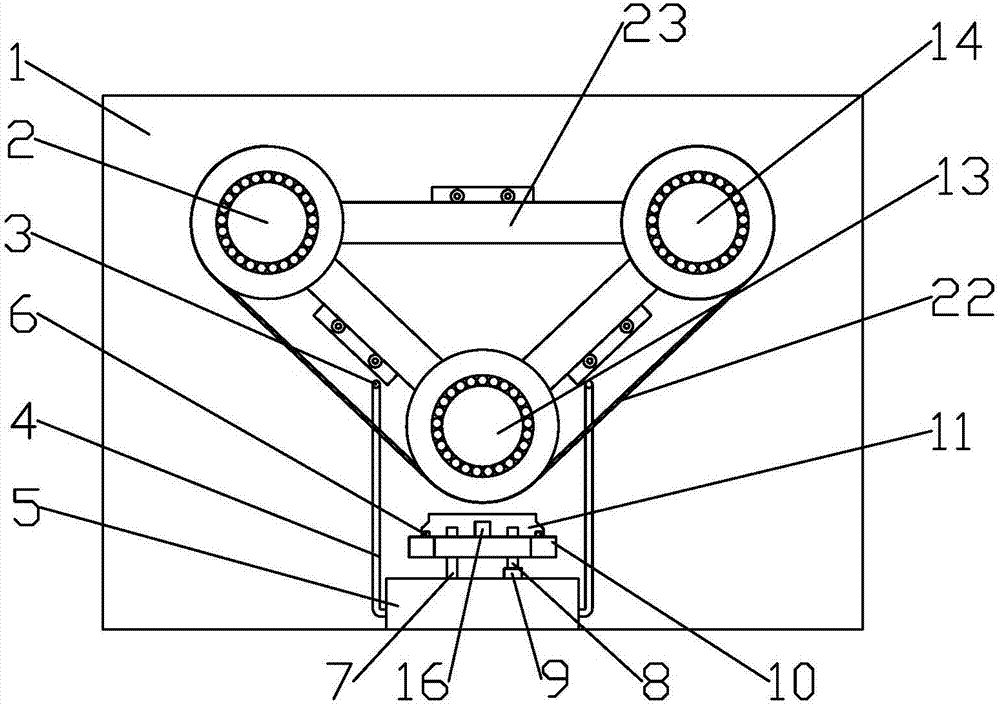

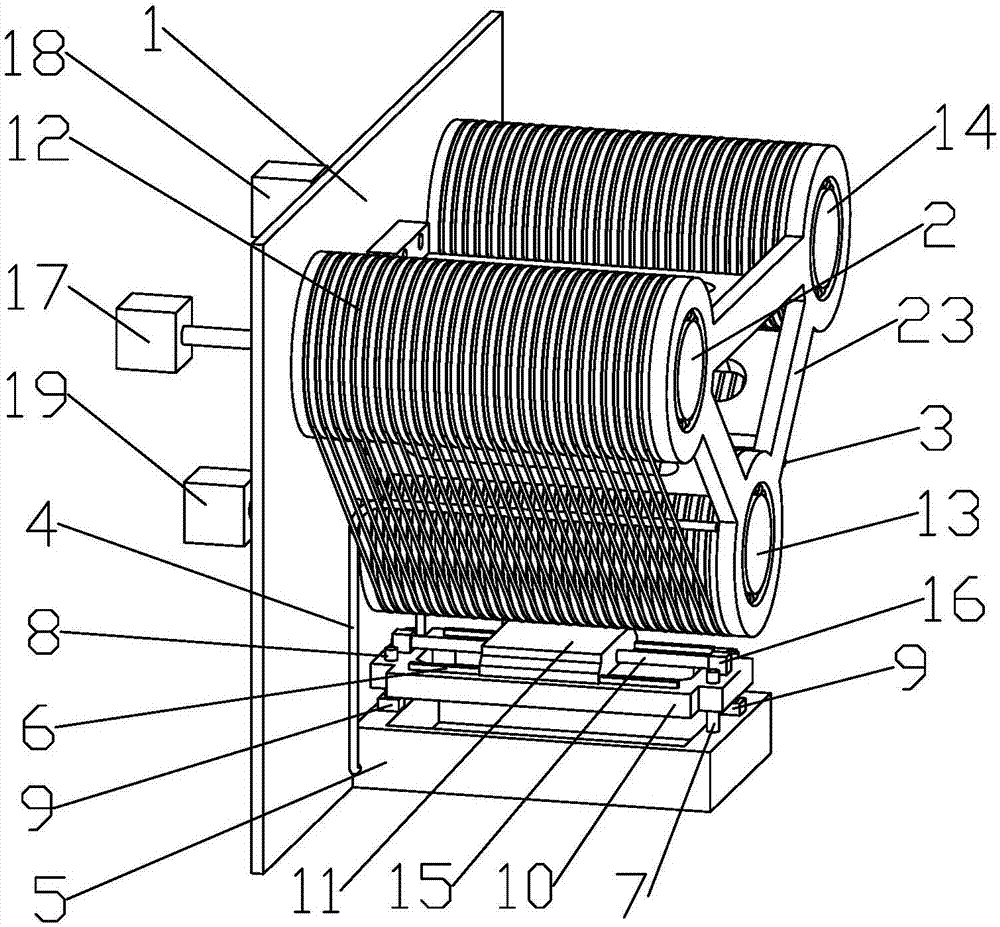

[0037] A contact type wire belt grinding device of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0038]A contact type wire belt grinding processing device of the present invention is a new type of processing device integrating traditional abrasive belt grinding and a newly developed diamond wire. The base of the diamond wire is steel wire, and a layer of artificial diamond abrasive particles is evenly consolidated on the surface. The two wire collecting wheels and the pressure grinding wheel have the same axial length and are arranged in parallel, and the specific arrangement orientation in space can be changed according to the actual working conditions. There are densely arranged grooves on the wheel to constrain the diamond wires. The distance between adjacent grooves is equal and parallel to each other, but they are not connected. The diamond wire is wound out from the left wire collection wheel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com