Soft projectile body polishing grinding head

A technology of polishing grinding head and soft elastic body, which is applied to the parts of grinding machine tools, grinding/polishing equipment, drilling/drilling equipment, etc., which can solve the problems of large friction coefficient and high heat generation of soft grinding heads, and achieve The effect of low grinding temperature, less grinding heat and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

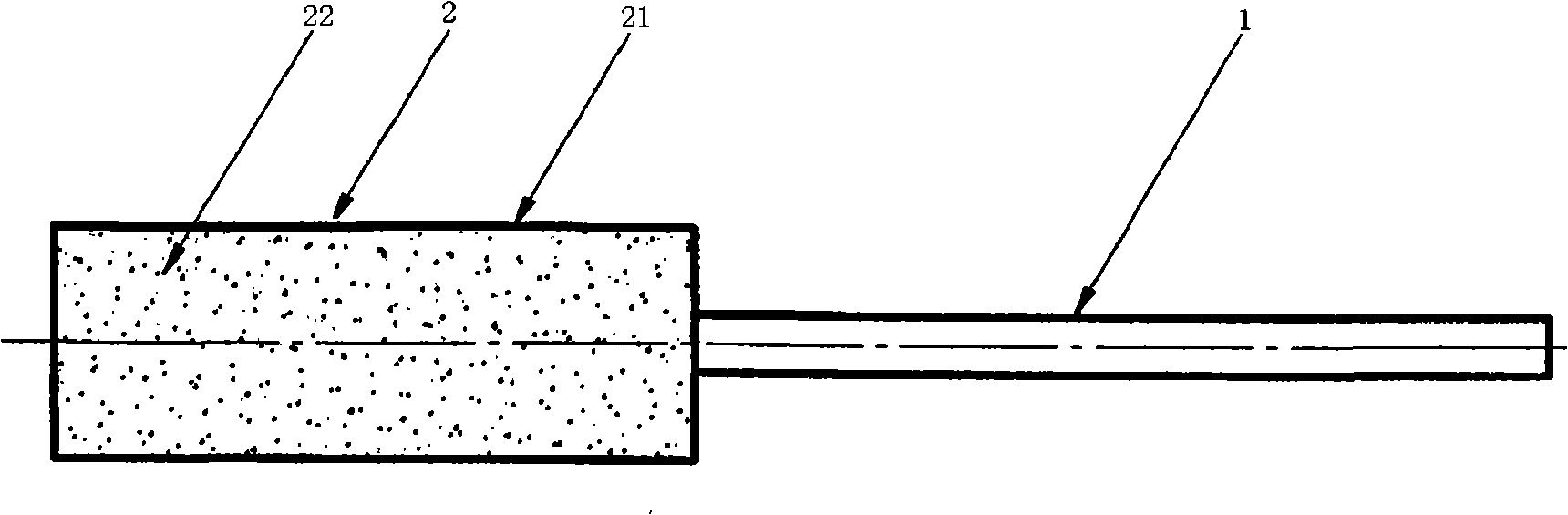

[0021] Example 1, see figure 1 , a soft elastic body polishing head, including a rotating shaft 1 connected with a motor, and a polishing head 2 arranged at the other end of the rotating shaft 1, the polishing head 2 is composed of a grinding core 21 fixedly arranged on the rotating shaft and uniformly planted Abrasive grains 22 that enter the surface of the grinding core. The grinding core 21 is made of elastic rubber-plastic material, and the abrasive grains 22 are needle-shaped with their sharp edges facing outward. The polishing head 2 is cylindrical.

[0022] Utilizing the principle of high-voltage electrostatic adsorption and electrostatic sand planting method, the abrasive grains 22 are uniformly implanted on the surface of the grinding core 21 made of EVA material, and the distribution is even and tightly arranged. The selected abrasive grains 22 have basically the same particle size, and have good contour performance. Abrasive grains 22 have sharp edges facing outw...

Embodiment 2

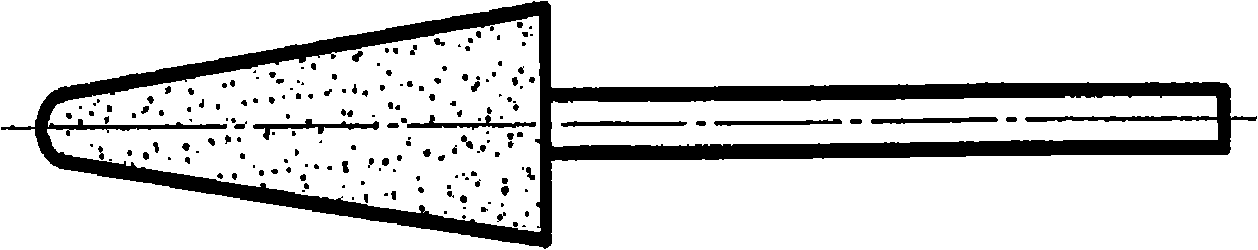

[0029] Example 2, see figure 2 , the polishing head 2 is a conical round head, and all the other are the same as in Embodiment 1.

Embodiment 3

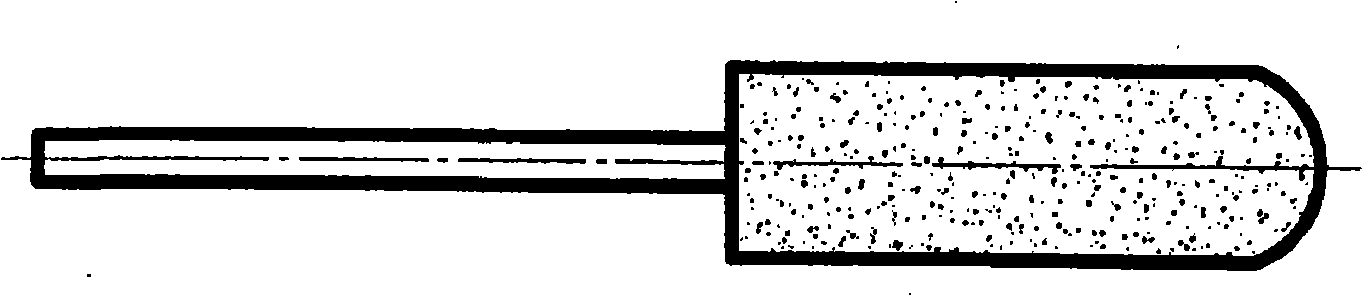

[0030] Embodiment 3, see image 3 , the polishing head 3 is a round cylindrical shape, and the rest are the same as in Embodiment 1.

[0031] The grinding head can also be made into various sizes and shapes to meet the requirements of different grinding pins.

[0032] Compared with the prior art, the grinding core of the present invention adopts EVA rubber and plastic material. EVA has the advantages of good cushioning, shock resistance, heat insulation, moisture resistance, chemical corrosion resistance, etc., and is non-toxic, non-absorbent, non-polluting environment, and the grinding core has good softness, which belongs to soft elastic body and has good flexibility to adapt to irregularities. The advantages of curved surface polishing; compared with grinding wheel grinding, the grinding heat is less, the grinding temperature is lower, the workpiece is not easily deformed, and the processed surface is not prone to defects such as overburning and cracks, and it is easy to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com