Hole making method for ultrasonic vibration assisted grinding of SiCp/Al composite

A technology of ultrasonic vibration and composite materials, which is applied to the parts of grinding machine tools, grinding/polishing equipment, manufacturing tools, etc. It can solve the problems of difficult discharge of grinding heat, temperature rise of grinding area, thermal damage of processed materials, etc. , to improve machining accuracy and quality, reduce axial grinding force, and reduce tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The embodiment of the present invention discloses a hole making method for ultrasonic vibration-assisted grinding of SiCp / Al composite material. The hole making method is as follows:

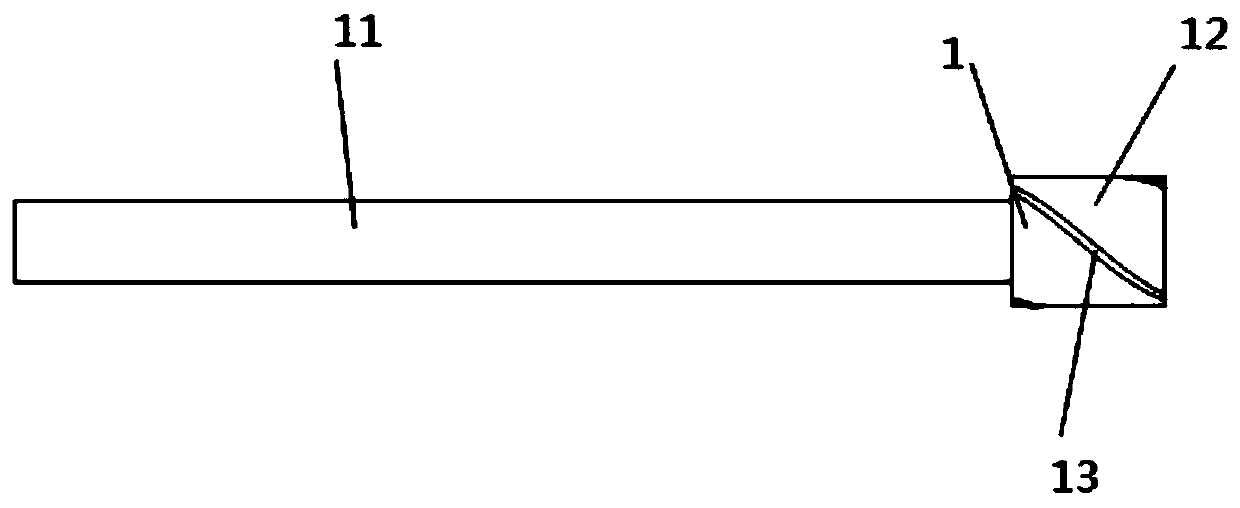

[0037] Step (1), the SiCp / Al composite material is drilled through a grinding tool to make holes. The grinding tool 1 includes: a cutter head 12 and a cutter handle 11; the cutter head 12 and the cutter handle 11 are fixedly connected;

[0038] The cutter head 12 is made by mixing abrasive and bonding agent;

[0039] The cutter head 12 needs to be selected before grinding. The cutter head 12 is selected mainly from three aspects: abrasive, bonding agent and particle size;

[0040] Abrasive selection: The reinforcement in the SiCp / Al composite material is SiC particles, and its hardness is very high. In order to ensure the wear resistance of the grinding tool 1 and increase its service life, diamonds with higher hardness than SiC particles should be used as abrasives , Where, such as figure 1 The ...

Embodiment 2

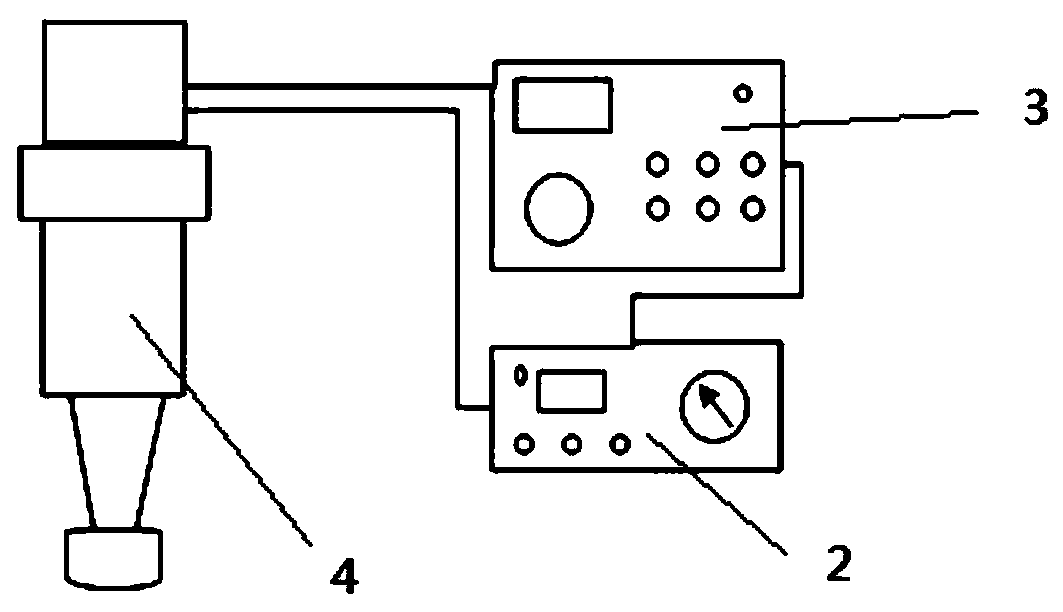

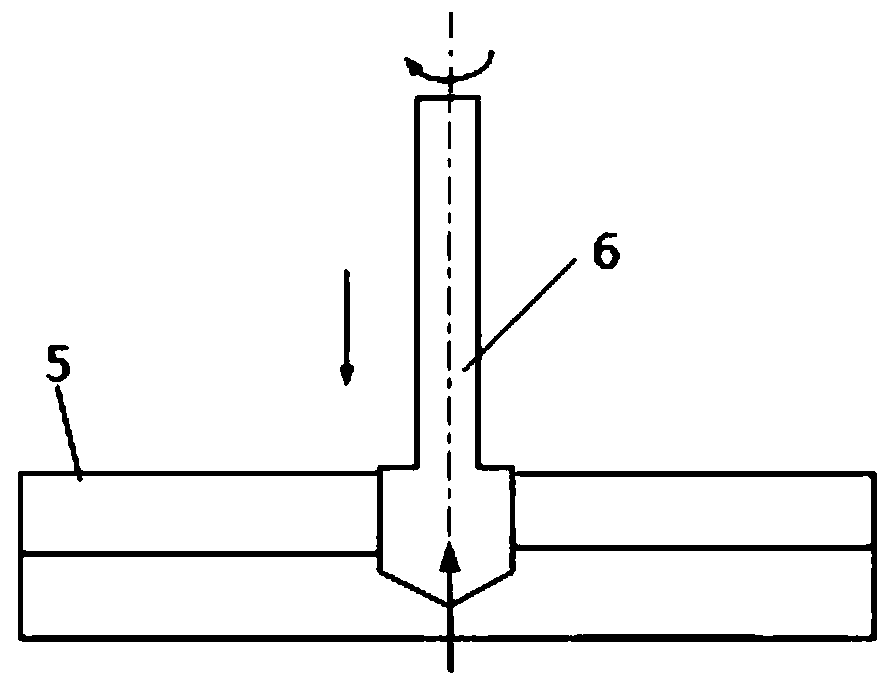

[0048] The aluminum-based composite material is used as the test material, the reinforcement is SiC particles, the volume fraction is 45%, the particle size is 2-8μm, and electroplated diamond grinding tools are used. Axial force is an important factor affecting the quality of composite holes, and it is the direct cause of various defects. This is mainly because the main cutting edge of the ordinary grinding tool 6 is the front face of the grinding tool. At a certain moment, the end face of the grinding tool is in contact with the material for processing such as image 3 As shown, a larger axial force will be generated. When electroplated diamond grinding tools are used for hole making, such as Figure 4 As shown, the cutter head 12 part of the grinding tool 1 is ground with a diamond with a higher hardness than SiC. It has a large contact area with the material, which can effectively reduce the axial force, and three equally spaced chip grooves 13 are attached, which is benefi...

Embodiment 3

[0050] The workpiece material is SiCp / Al composite material, and the grinding tool 1 in Example 1 is used for processing on the DMU80monoBLOCK 5-axis high-speed machining center. Because the cutting speed required for grinding is relatively high, the spindle speed is 4000RPM and the ultrasonic frequency is 26KHZ. The middle value of the amplitude is 6μm, the processing aperture is 8mm, and the hole depth is 4mm. During the processing, each hole needs to be processed for 6 minutes.

[0051] The processing parameters in this embodiment are shown in the table:

[0052] Table 1

[0053]

[0054] It can be seen from Table 1 that the ultrasonic vibration assisted grinding method is adopted in the present invention, and a suitable grinding tool is selected to quickly and accurately realize the hole-making of the SiCp / Al composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com