Resin grinding wheel and manufacturing method thereof

A technology of resin grinding wheel and grinding wheel, which is applied in the direction of bonding grinding wheel, manufacturing tools, metal processing equipment, etc., can solve the problems of metal corrosion, achieve the effects of preventing corrosion, improving the strength of grinding wheel, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

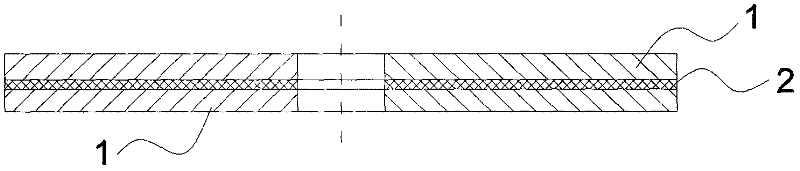

[0037] The resin grinding wheel to be prepared in this embodiment is a parallel grinding wheel, such as figure 1 shown.

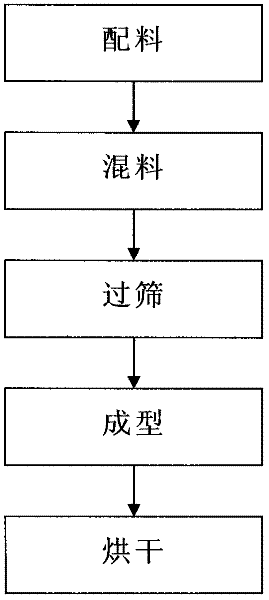

[0038] First, weigh raw materials with a certain weight ratio for batching. The types of raw materials and their parts by weight are 60 parts of brown corundum, 90 parts of single crystal corundum, 20 parts of green silicon carbide, 65 parts of phenolic resin powder, and phenolic resin liquid 10 parts, quicklime powder 20 parts, pyrite powder 25 parts, cryolite powder 8 parts.

[0039] Then, put abrasives such as brown corundum, single crystal corundum, and green silicon carbide into the phenolic resin solution for soaking, and stir sufficiently to make the surface of the abrasive grains fully adhere to the phenolic resin solution. After sufficient infiltration, mix phenolic resin powder, quicklime powder, pyrite powder and cryolite with brown corundum, and continue to stir until the various raw materials are fully mixed and even.

[0040] The mixed raw m...

Embodiment 2

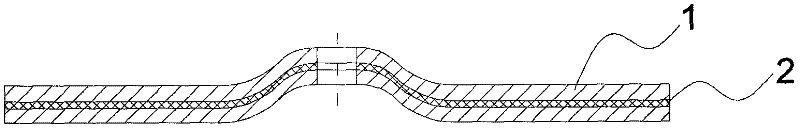

[0044] The resin grinding wheel to be prepared in this embodiment is a cymbal type grinding wheel, such as figure 2 shown.

[0045] Similarly, batching is carried out at first, and the types of raw materials and their parts by weight are respectively 150 parts of brown corundum, 58 parts of phenolic resin powder, 16 parts of phenolic resin liquid, 10 parts of quicklime powder, 12 parts of pyrite powder, 5 parts of cryolite powder, charcoal Black 2 parts.

[0046] Then, the same mixing and sieving steps as in the first embodiment were carried out.

[0047] The forming steps for cymbal wheels are slightly different from those for parallel wheels. Similarly, for example, to mold three grinding wheels at one time, first weigh three parts of molding materials, each of which is just or slightly more than the weight required to manufacture one resin grinding wheel. In the same way, put half of the molding material in the forming mold and spread it flat, cover the reinforcement sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com