Preparation method of high-strength durable porous diamond grinding wheel

A diamond grinding wheel, high-strength technology, used in metal processing equipment, manufacturing tools, ceramic products, etc., can solve the problems of insufficient grinding wheel strength, easy falling off of grinding wheel abrasives, short service life, etc. The effect of densification and improvement of interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

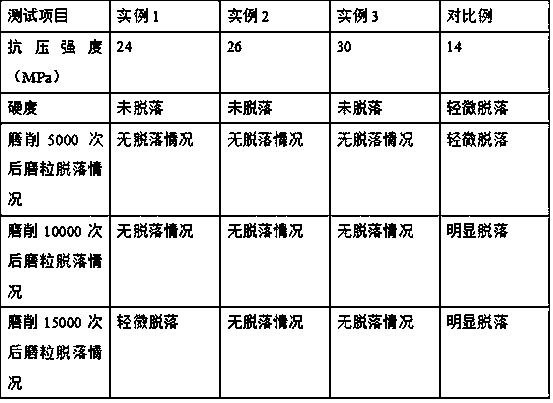

Examples

example 1

[0027] In parts by weight, pour 20 parts of silicon dioxide, 15 parts of alumina, 30 parts of calcium carbonate, 15 parts of zirconia, 10 parts of sodium carbonate, 10 parts of potassium carbonate, 8 parts of aluminum carbonate, and 40 parts of boric acid into the corundum ball mill In the altar, the diameter of the corundum ball is 30mm, the rotation speed of the ball mill altar is set to 80r / min, and the ball is milled for 30 minutes to obtain the ball abrasive powder; pour the ball abrasive powder into the crucible furnace, heat up to 1300°C, and keep it for 30 minutes to obtain a fusion bond Plug the plugging rod, put an enamel container filled with water at the outlet of the crucible furnace, use the plugging rod to drain the molten bonding agent into the enamel container for water quenching for 3 minutes, and collect the ceramic bonding agent in the enamel container. agent fragments; mix the above vitrified bond fragments with water and other qualities, pour them into the...

example 2

[0029] In parts by weight, pour 22 parts of silicon dioxide, 20 parts of alumina, 32 parts of calcium carbonate, 17 parts of zirconia, 11 parts of sodium carbonate, 12 parts of potassium carbonate, 9 parts of aluminum carbonate, and 45 parts of boric acid into the corundum ball mill In the altar, the diameter of the corundum ball is 35mm, the rotation speed of the ball mill altar is set to 90r / min, and the ball mill is 32min to obtain the ball abrasive powder; pour the ball abrasive powder into the crucible furnace, heat up to 1320°C, and keep it for 35min to obtain a fusion bond Plug the plugging rod, put an enamel container filled with water at the outlet of the crucible furnace, use the plugging rod to drain the molten bonding agent into the enamel container for water quenching for 3 minutes, and collect the ceramic bonding agent in the enamel container. agent fragments; mix the above-mentioned vitrified bond fragments with water and other qualities, pour them into a corundu...

example 3

[0031] In parts by weight, pour 25 parts of silicon dioxide, 25 parts of alumina, 35 parts of calcium carbonate, 20 parts of zirconia, 12 parts of sodium carbonate, 15 parts of potassium carbonate, 10 parts of aluminum carbonate, and 50 parts of boric acid into the corundum ball mill In the altar, the diameter of the corundum ball is 50 mm, the rotation speed of the ball mill altar is set to 100 r / min, and the ball mill is 35 minutes to obtain the ball mill powder; pour the ball mill powder into the crucible furnace, heat up to 1350 ° C, and keep it for 40 minutes to obtain a fusion bond agent, plug the plugging rod, put an enamel container filled with water at the discharge port of the crucible furnace, use the plugging rod to drain the molten bonding agent into the enamel container for water quenching for 4 minutes, and collect the ceramic bonding agent in the enamel container. agent fragments; mix the above vitrified bond fragments with water and other qualities, pour them i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com