Preparation method for wear-resisting man-made oilstone

A whetstone and man-made technology, applied in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of insufficient bonding degree of artificial whetstone and poor grinding effect, achieve good cooling and lubrication, and improve processing quality , The effect of preventing the pores from being too large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

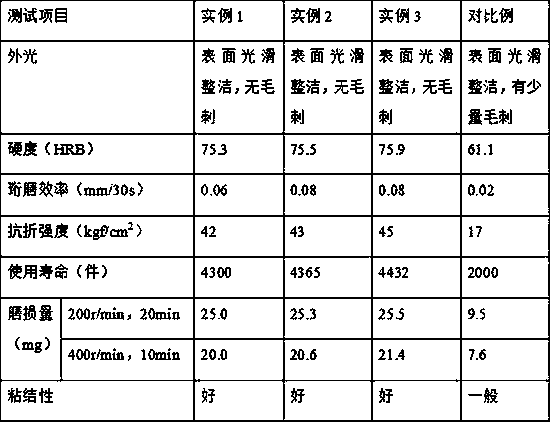

Examples

example 1

[0027] In parts by weight, pour 20 parts of silicon dioxide, 15 parts of alumina, 30 parts of calcium carbonate, 15 parts of zirconia, 10 parts of sodium carbonate, 10 parts of potassium carbonate, 8 parts of aluminum carbonate, and 40 parts of boric acid into the corundum ball mill In the altar, add corundum balls with a diameter of 30mm, set the rotation speed of the ball mill altar to 80r / min, and the ball milling time to 30min to obtain the ball mill powder; pour the ball mill powder into the crucible furnace, heat up to 1300°C, and keep warm After 30 minutes, get the molten binder, plug the plugging rod, use the plugging rod to drain the molten binder into an enamel container filled with water, quench in water for 3 minutes, collect the broken pieces of the vitrified binder, mix the broken pieces of the porcelain binder with water Mix with equal mass, pour into corundum ball milling altar and continue ball milling for 20h, control ball milling speed to 40r / min, get ball mi...

example 2

[0029] In parts by weight, pour 23 parts of silicon dioxide, 20 parts of alumina, 33 parts of calcium carbonate, 17 parts of zirconia, 11 parts of sodium carbonate, 13 parts of potassium carbonate, 9 parts of aluminum carbonate, and 45 parts of boric acid into the corundum ball mill In the altar, add corundum balls with a diameter of 40mm, set the rotation speed of the ball mill altar to 90r / min, and the ball milling time to 33min to obtain the ball mill powder; pour the ball mill powder into the crucible furnace, heat up to 1325°C, and keep warm 35min, get the molten binder, plug the plugging rod, use the plugging rod to drain the molten binder into an enamel container filled with water, quench in water for 3.5min, collect the vitrified bond fragments, and mix the porcelain bond fragments with Mix water and other qualities, pour it into a corundum ball mill altar and continue ball milling for 22 hours, control the ball milling speed to 50r / min to obtain a ball mill slurry, pou...

example 3

[0031] In parts by weight, pour 25 parts of silicon dioxide, 25 parts of alumina, 35 parts of calcium carbonate, 20 parts of zirconia, 12 parts of sodium carbonate, 15 parts of potassium carbonate, 10 parts of aluminum carbonate, and 50 parts of boric acid into the corundum ball mill In the altar, add corundum balls with a diameter of 50mm, set the rotation speed of the ball mill altar to 100r / min, and the ball milling time to 35min to obtain the ball mill powder; pour the ball mill powder into the crucible furnace, heat up to 1350°C, and keep warm After 40 minutes, get the molten binder, plug the plugging rod, use the plugging rod to drain the molten binder into an enamel container filled with water, quench in water for 4 minutes, collect the broken pieces of the vitrified binder, mix the broken pieces of the porcelain binder with water Mix with equal mass, pour into corundum ball milling altar and continue ball milling for 24 hours, control ball milling speed to 60r / min to ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com