Core-shell nano fiber type self-healing carbon fiber composite material and preparation method thereof

A nanofiber and composite material technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of long curing time and poor healing effect, and achieve the effect of easy operation, improved interlayer performance, and stable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

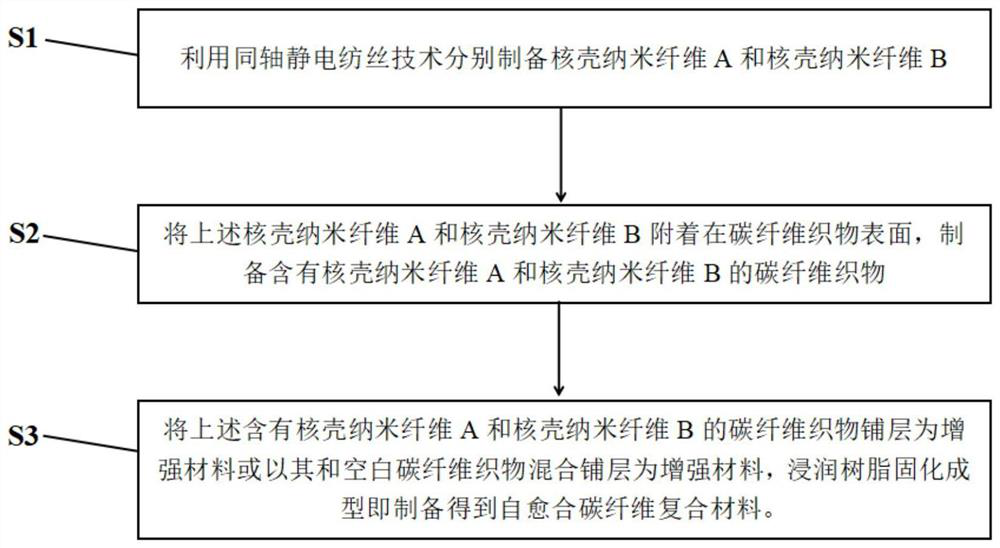

[0018] see figure 1 , the first aspect of the present invention provides a method for preparing a core-shell nanofiber type self-healing carbon fiber composite material, comprising the following steps:

[0019] S1 uses coaxial electrospinning technology to prepare core-shell nanofiber A and core-shell nanofiber B respectively; wherein, the core layer material in core-shell nanofiber A is bisphenol A epoxy resin and bisphenol F epoxy resin One or two of them, which are healing agent resins, have a viscosity range of 500-5000mPa.s, preferably 500-2500mPa.s, and further 2500mPa.s. The flow in the crack, so that the healing agent quickly fills the damaged area and shortens the healing time; the core layer material in the core-shell nanofiber B is a highly active curing agent, which is conducive to improving the healing speed, specifically isophorone diamine, poly One or more of mercaptan, ethylenediamine, polyethylene polyamine, which is a curing agent curing agent; the shell mat...

Embodiment 1

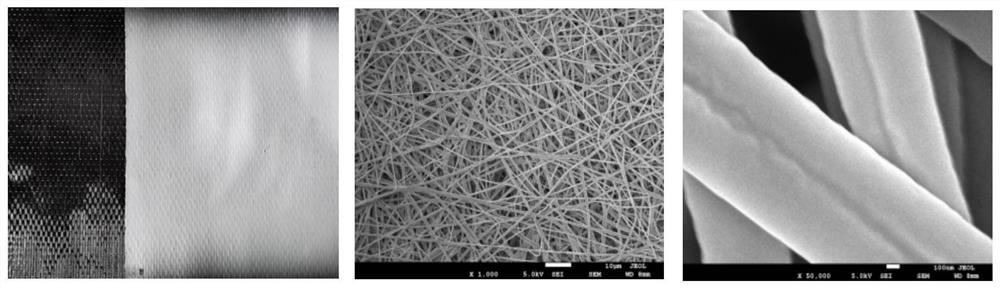

[0036] Add the shell spinning solution with a mass fraction of 9wt% (N,N-dimethylformamide solution of acrylonitrile) into the outer needle barrel, and add bisphenol F epoxy resin (viscosity 2500mPa.s) into the inner needle Syringe; among them, the injection speed of the outer needle is set to 0.9ml / h, and the injection speed of the inner needle is set to 0.07ml / h; the positive pressure of the power supply is set to 13KV, and the negative pressure is set to -1KV; the temperature is 30°C, and the humidity is 50% ; After the electrospinning parameters are adjusted, fix the T700 carbon fiber unidirectional cloth on the roller collector, then start the electrospinning machine for spinning, the roller speed is set to 50rpm, and the distance from the needle to the roller is 15cm. At this time, the nanofiber Start to deposit on the surface of the carbon fiber unidirectional cloth, and the spinning time is 120min to obtain a carbon fiber fabric containing the core-shell nanofiber A;

...

Embodiment 2

[0040] Add the shell spinning solution (N,N-dimethylformamide solution of acrylonitrile) with a mass fraction of 20wt% into the outer needle barrel, and add bisphenol F epoxy resin (viscosity 1500mPa.s) into the inner needle Syringe; among them, the injection speed of the outer needle is set to 0.5ml / h, and the injection speed of the inner needle is set to 0.1ml / h; the positive pressure of the power supply is set to 13KV, and the negative pressure is set to -1KV; the temperature is 30°C, and the humidity is 50% ; After the electrospinning parameters are adjusted, fix the T700 carbon fiber unidirectional cloth on the roller collector, then start the electrospinning machine for spinning, the roller speed is set to 50rpm, and the distance from the needle to the roller is 15cm. At this time, the nanofiber Start to deposit on the surface of the carbon fiber unidirectional cloth, and the spinning time is 90min to obtain a carbon fiber fabric containing the core-shell nanofiber A;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com