Temporary plugging well killing fluid for fractured reservoirs, and application and preparation method thereof

A technology for fractured reservoirs and well-killing fluids, which is applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., and can solve the problem that the pressure bearing capacity cannot meet the downhole working environment of ultra-low pressure coefficient formations and poor high temperature adaptability , poor flowback performance and other problems, to achieve the effects of reducing reservoir damage, high pressure bearing capacity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a temporary plugging and killing fluid for fractured reservoirs, including a base fluid and degradable shape memory polymer particles, the base fluid is a composite gel, and the degradable shape memory polymer particles are composed of Composition of polymers with different deformation recovery amounts, the degradable shape-memory polymer particles are carried by the base fluid and pumped into the reservoir, and after entering the fractured reservoir, they expand and recover their shape in response to temperature.

[0041] Application process:

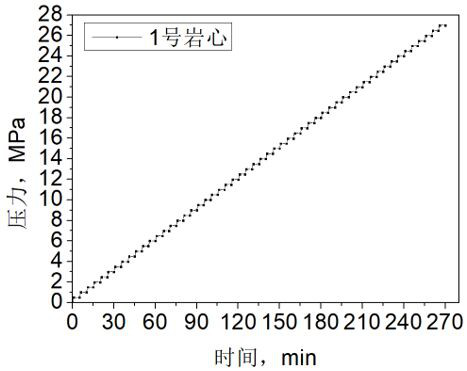

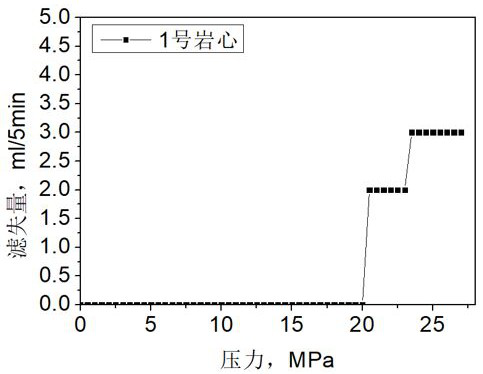

[0042] The base fluid carries degradable shape memory polymer particles and is pumped into the reservoir. The degradable shape memory polymer particles can be evenly dispersed in the base fluid. Glue, which isolates the upper liquid column, degradable shape memory polymer particles enter the fractured reservoir and expand in response to temperature and restore their shape, self-adaptively block the chann...

Embodiment 2

[0044] On the basis of Example 1, this example provides a temporary plugging and killing fluid for fractured reservoirs, wherein the amount of the degradable shape memory polymer particles is 0.1-0.5% by mass of the base fluid.

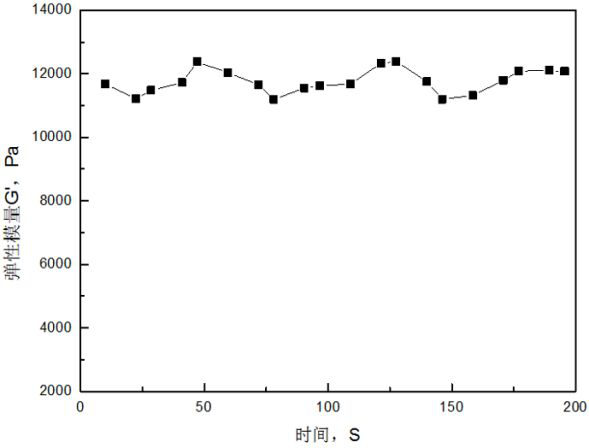

[0045] Among them, the base fluid is a composite gel, which has good fluidity at ground temperature, and can carry degradable shape memory polymer particles to pump into the reservoir, and cross-link at the reservoir temperature to form a high-elastic and low-viscosity gel to isolate the upper liquid column , to prevent natural gas invasion in the wellbore. The degradable shape-memory polymer particles are composed of different proportions of deformation recovery. They are pumped into the fractured reservoir with the base fluid and then expand and restore their shape in response to temperature, blocking the channels of fractures of various sizes.

[0046] The temporary plugging and killing fluid can realize temporary plugging and killing of fractured ...

Embodiment 3

[0048] On the basis of Example 1, this example provides a temporary plugging and killing fluid for fractured reservoirs, the base fluid is composed of the following raw material components in mass percent: polymer 1-5%; cross-linked 0.1-3% agent; 1-5% nano-inorganic material; 0.01-0.1% initiator, 0.1-0.2% dispersant; 0.1-1% capsule breaker; the balance is water.

[0049] The base fluid gel involved in the present invention has the characteristics of high elasticity and low viscosity after the formation is gelled, does not adsorb and stay on the wellbore pipe wall and the formation, and has a certain pressure bearing capacity. After gelation, the gel can effectively prevent gas from passing through , After the job is completed, according to the next process, you can choose different ways to break the glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com