Novel connecting rod plunger piston mechanism of press machine

A press and connecting rod technology, applied in the field of press machinery, can solve the problems of difficult maintenance, easy deformation of connecting pins, rapid damage of plunger, etc., achieve inconvenient lubrication and difficult maintenance, avoid bearing large stamping force, and compact overall structure Effect

Inactive Publication Date: 2012-08-15

赵亚州

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a new type of press connecting rod plunger mechanism, which overcomes the problems that the connecting pins of the existing press connecting rod plungers bear high punching force, the connecting pins are easily deformed, the plunger is damaged quickly, and the lubrication is not good. Defects of convenience and difficult maintenance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

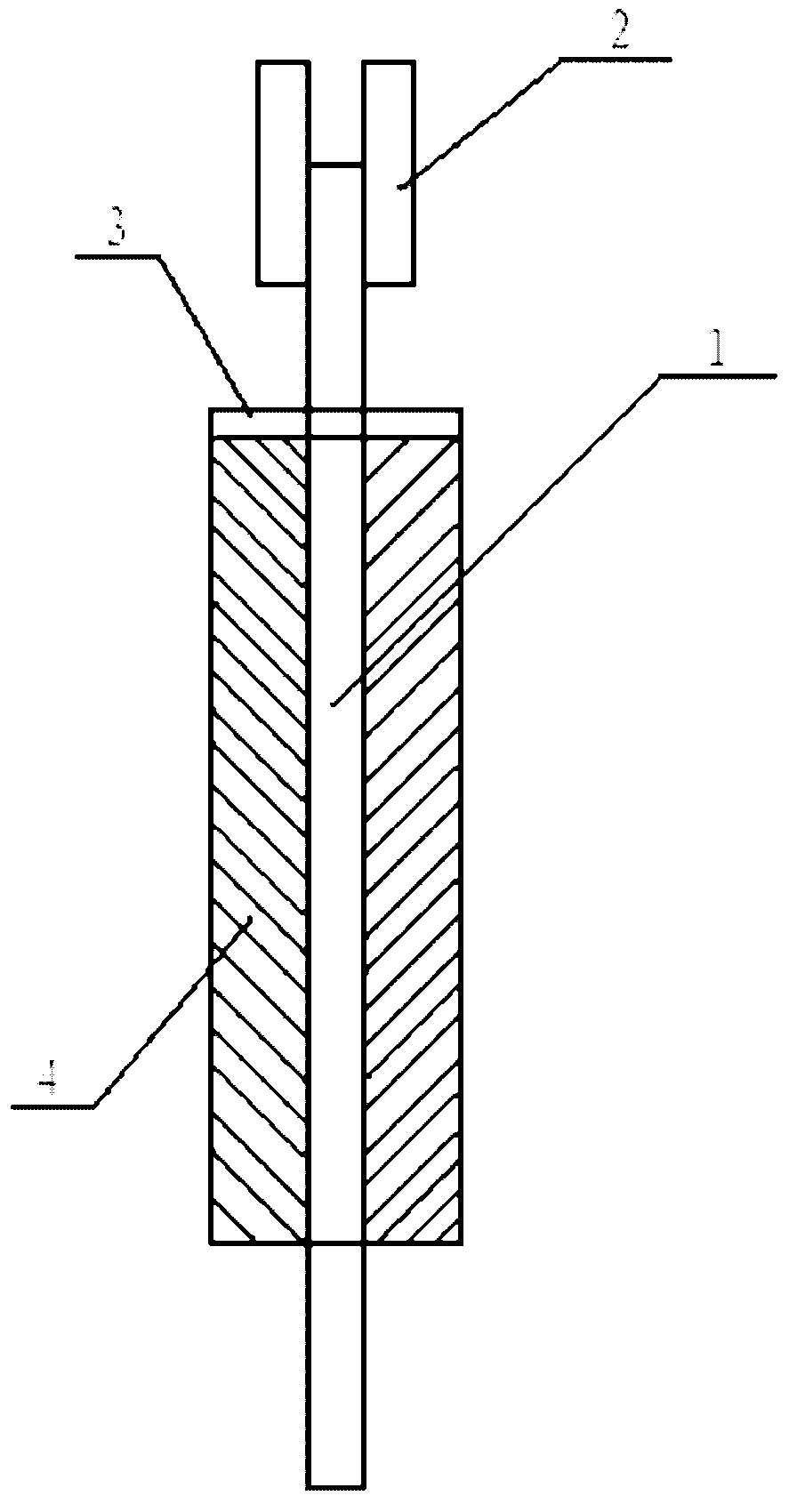

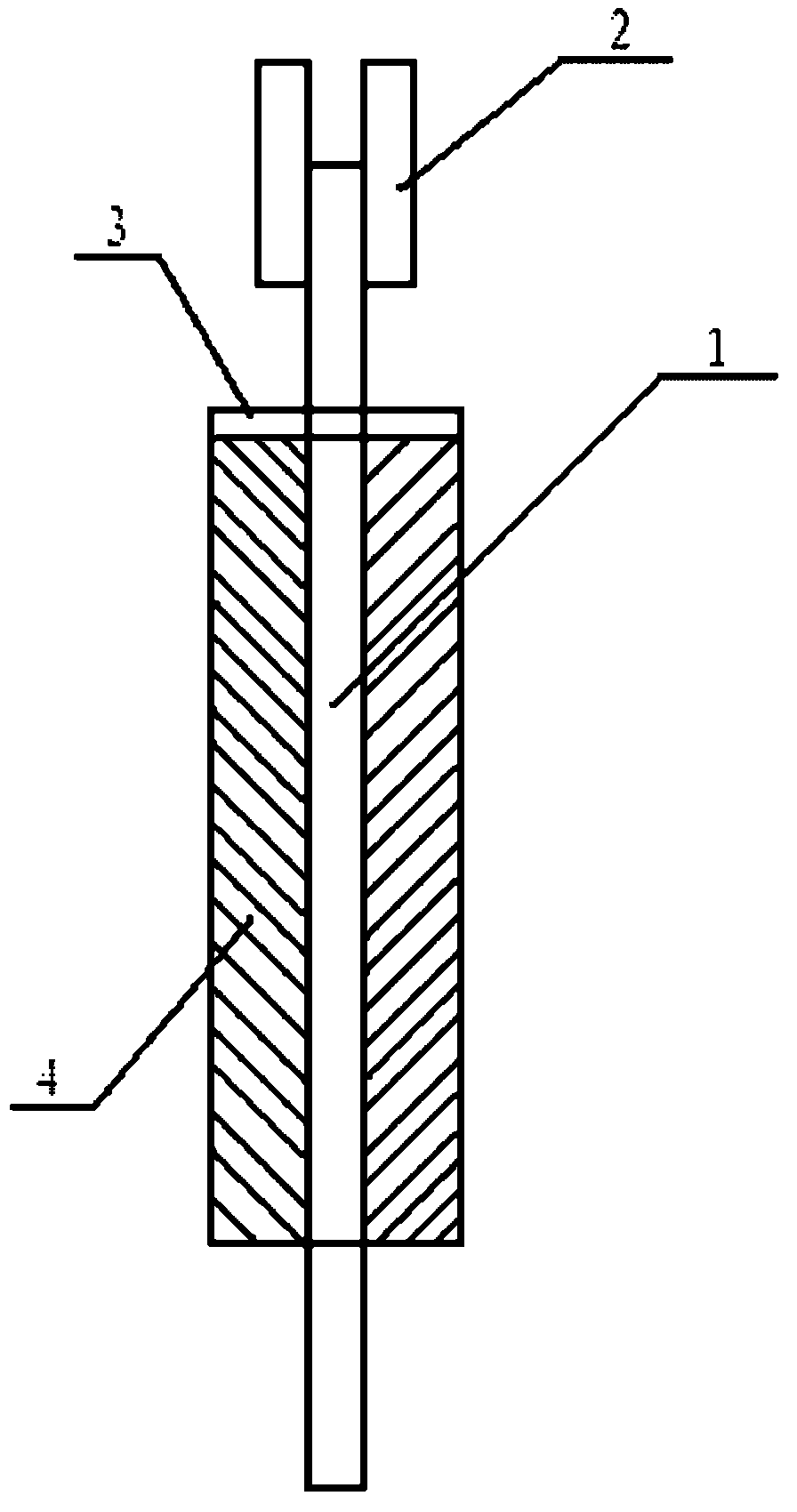

[0009] The connecting rod plunger mechanism has a press connecting rod (1), and a one-way connecting pin (2) is arranged on the top of the press connecting rod (1), and a steel alloy tile is installed on the upper half of the press connecting rod (1). (3); The press connecting rod (1) and the steel alloy tile (3) are installed in the holes of the double cover plunger (4).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a novel connecting rod plunger piston mechanism of a press machine; a one-way connecting pin is arranged on the top of a connecting rod of the press machine; the upper half end of the connecting rod of the press machine is provided with a rigid alloy tile; and the connecting rod of the press machine and the rigid alloy tile are arranged in holes of two sets of plunger pistons. After the scheme is adopted, the defects that the connecting pin is easy to deform due to large stamping force, and the plunger pistons are rapidly damaged, inconvenient to lubricate and difficult to maintain can be effectively avoided; and furthermore, the parts are small in volume, so that the whole structure of the press machine is compact.

Description

technical field [0001] The invention relates to a connecting rod plunger mechanism, in particular to a novel press connecting rod plunger mechanism, which belongs to the technical field of pressure machinery. Background technique [0002] At present, the connecting rod plunger used in all presses adopts a double-joint mechanism or a three-point connecting rod plunger mechanism. In this mechanism, the connecting pin bears a large stamping force, the connecting pin is easily deformed, and the plunger is damaged. Fast, inconvenient lubrication and difficult maintenance defects. Contents of the invention [0003] The purpose of the present invention is to provide a new type of press connecting rod plunger mechanism, which overcomes the problems that the connecting pins of the existing press connecting rod plungers are subjected to high punching force, the connecting pins are easily deformed, the plunger is damaged quickly, and the lubrication is not good. Defects of convenien...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B30B15/00

Inventor 赵亚州

Owner 赵亚州

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com