Fixed-point quantitative feeding machine

A mechanical and feeding tube technology, applied in the field of feeding, can solve the problems of uneven spreading, waste, neglect of feeding organisms, etc., and achieve the effect of preventing the slider from getting out of control, avoiding waste of feed, and preventing rapid shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

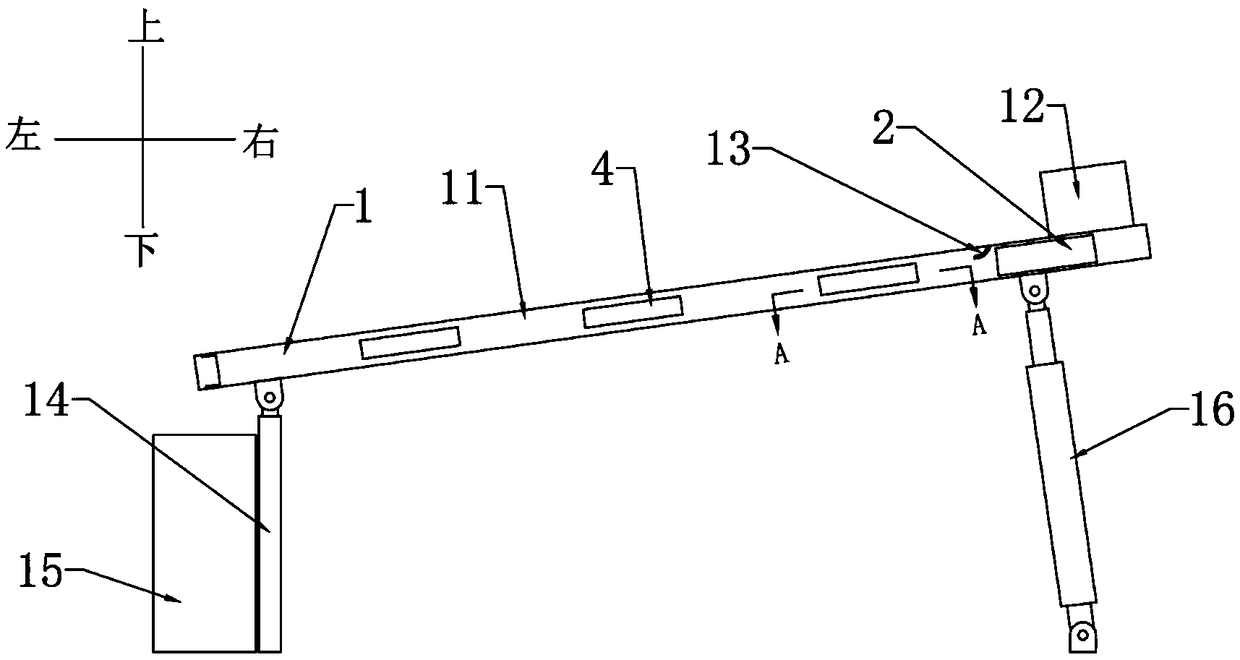

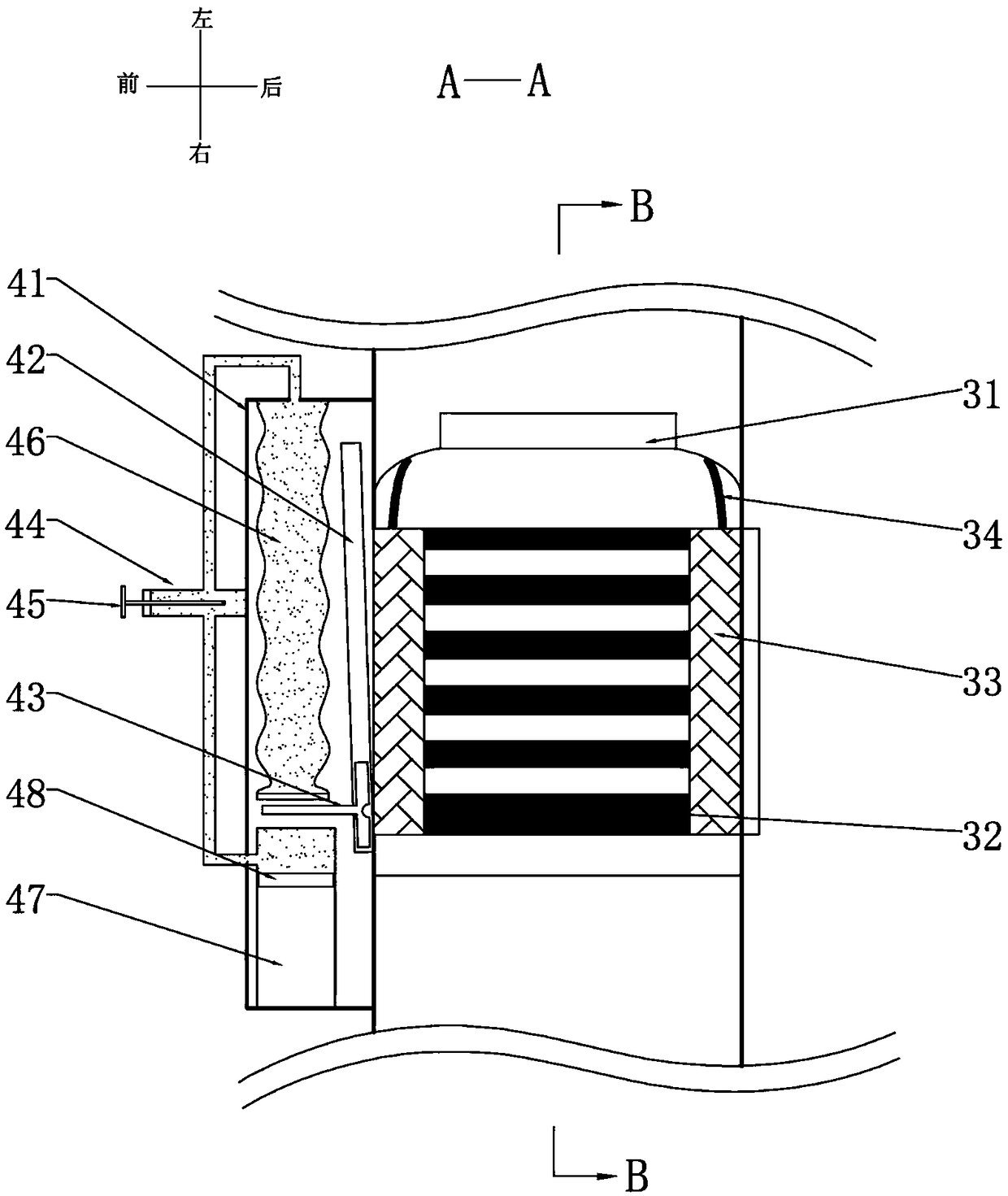

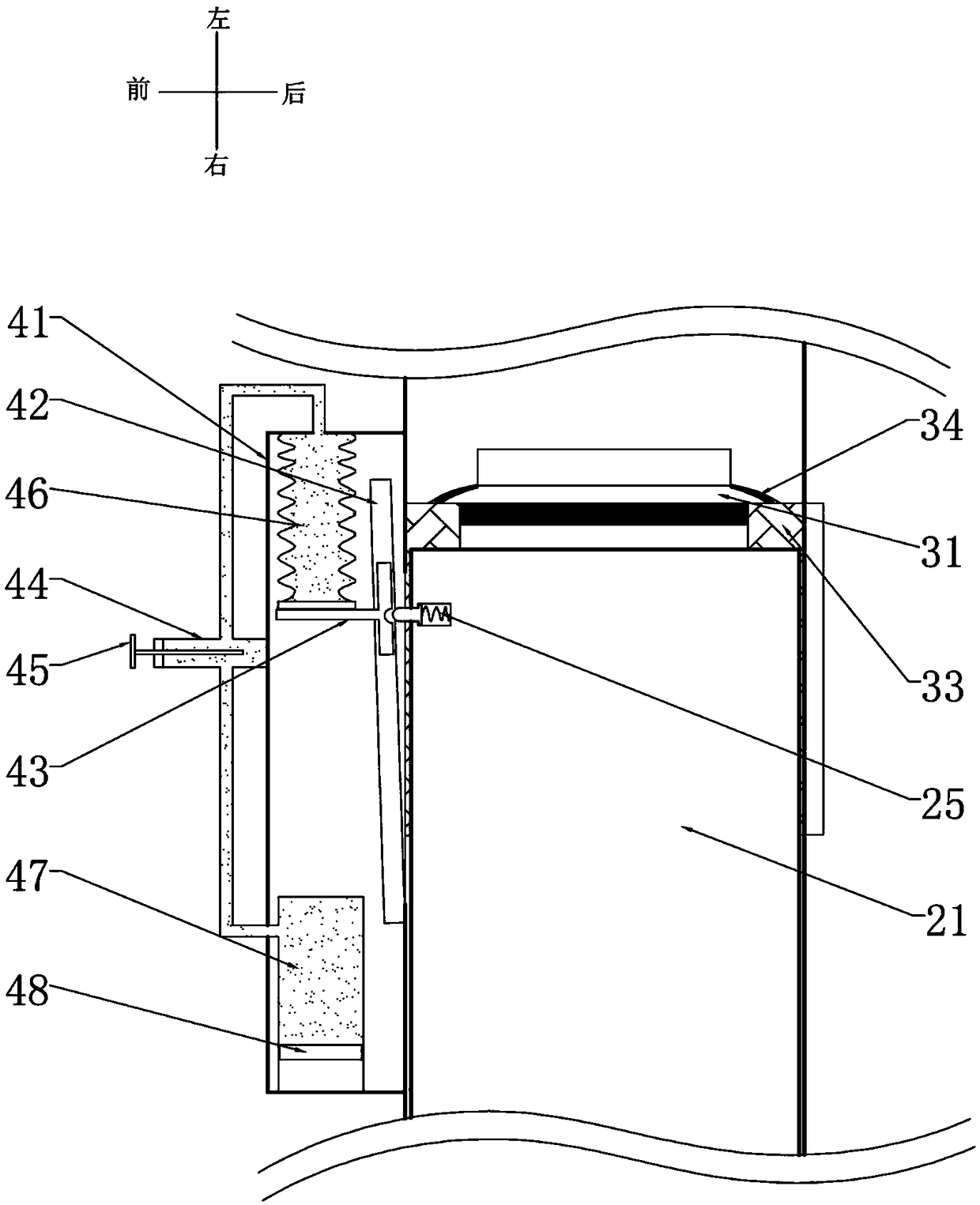

[0051] Such asfigure 1 As shown, a fixed-point quantitative feeding machine in this embodiment includes a carrier assembly 1 , a slider 2 , a slide plate assembly 3 and a deceleration assembly 4 .

[0052] Such as figure 1 , Figure 5 As shown, the carrying assembly 1 includes a feeding tube 11 , a feeding port 12 , a retaining spring 13 , a fixing rod 14 , a recovery bucket 15 and a telescopic rod 16 .

[0053] The feeding tube 11 is a hollow rod with a rectangular cross-section. The right end of the feeding tube 11 is closed and the left end runs through. Each group of strip grooves of the feeding tube 11 includes two upper and lower strip grooves parallel to the edges of the feeding tube 11, and there is a rectangular hole on the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com