Transparent wear-resistant film layer, plastic surface modification method and product

A technology of surface modification and wear-resistant film, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of high production cost, complicated process, difficult quality control, etc., and achieve enhanced stability and wear-resistant life, expand the application range, and improve the effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] 1) Place the PC sheet in deionized water and industrial high-purity ethanol or isopropanol for ultrasonic cleaning for 10 minutes to remove surface oil.

[0088] 2) After drying the PC sheet obtained above, load it in the chamber of the PECVD coating equipment, and vacuumize it to 1×10 -2 Below Pa, feed an inert gas (Ar or He) with a flow rate of 100 sccm, keep the vacuum at 0.5 Pa, load a 500V bias voltage on the turntable, set the ICP power to 300W, perform ion bombardment activation for 10 minutes, and then feed O 2 , the flow rate is 100sccm, the vacuum degree is kept at 0.5Pa, the bias voltage of 200V is loaded on the turntable, the ICP power is set to 500W, and the ion bombardment activation is performed for 10 minutes to increase the surface activity.

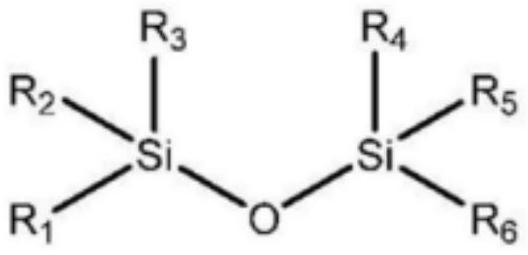

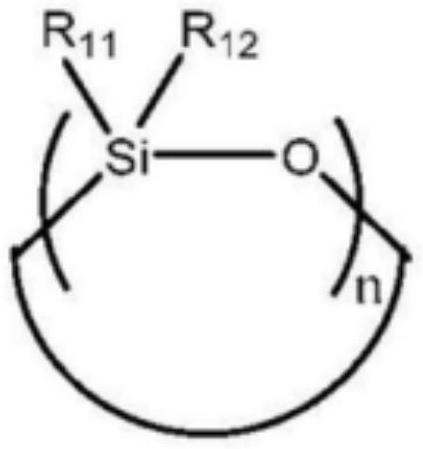

[0089] 3) Introduce hexamethyldisiloxane monomer vapor, the monomer flow rate is 300 μL / min, and at the same time, inject He and O 2 , the flow rates are 100sccm and 300sccm respectively, and the butterfly valve ...

Embodiment 2

[0092] 1) Place the PC sheet in deionized water and industrial high-purity ethanol or isopropanol for ultrasonic cleaning for 10 minutes to remove surface oil.

[0093] 2) After drying the PC material obtained above, load it in the chamber of the PECVD coating equipment, and vacuumize it to 1×10 -2 Below Pa, feed Ar with a flow rate of 100 sccm, keep the vacuum at 0.5 Pa, load a bias voltage of 500V on the turret, set the ICP power to 300W, perform ion bombardment activation for 10 minutes, and then feed H 2 , the flow rate is 100sccm, the vacuum degree is kept at 0.5Pa, the bias voltage of 200V is loaded on the turntable, the ICP power is set to 500W, and the ion bombardment activation is performed for 10 minutes to increase the surface activity.

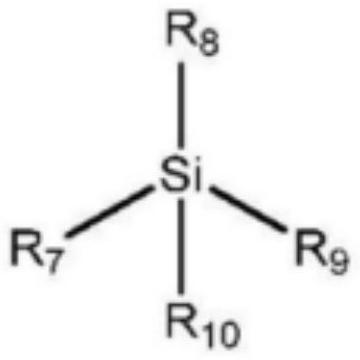

[0094] 3) Introduce tetraethoxysilane (TEOS) monomer steam, the monomer flow rate is 500μL / min, and at the same time, O 2 , the flow rate is 300sccm, and the butterfly valve is adjusted to maintain the vacuum pressure at 15Pa, a 6...

Embodiment 3

[0097] 1) Place the PC sheet in deionized water and industrial high-purity ethanol or isopropanol for ultrasonic cleaning for 10 minutes to remove surface oil.

[0098] 2) After drying the PC material obtained above, load it in the chamber of the PECVD coating equipment, and vacuumize it to 1×10 -2 Below Pa, feed an inert gas (Ar or He) with a flow rate of 100 sccm, keep the vacuum at 0.5 Pa, load a 500V bias voltage on the turntable, set the ICP power to 300W, perform ion bombardment activation for 10 minutes, and then feed O 2 , the flow rate is 100sccm, the vacuum degree is kept at 0.5Pa, the bias voltage of 200V is loaded on the turntable, the ICP power is set to 500W, and the ion bombardment activation is performed for 10 minutes to increase the surface activity.

[0099] 3) Introduce tetramethoxysilane (TMOS) monomer vapor, the monomer flow rate is 550μL / min, and at the same time, Ar and O 2 , the flow rates are 100sccm and 300sccm respectively, and the butterfly valve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com