High-efficient environmentally-friendly feed for quasipaa spinosa and preparation method of high-efficient environmentally-friendly feed

An environmentally friendly technology for Rana spinosa is applied in the field of high-efficiency and environment-friendly Rana spinosa feed and its preparation, which can solve the problems of affecting the healthy growth of Frog spinosa, difficulty in mass production, deterioration of aquaculture water, and the like, so as to improve the survival rate of farming , the effect of reducing body fat accumulation and reducing feed coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

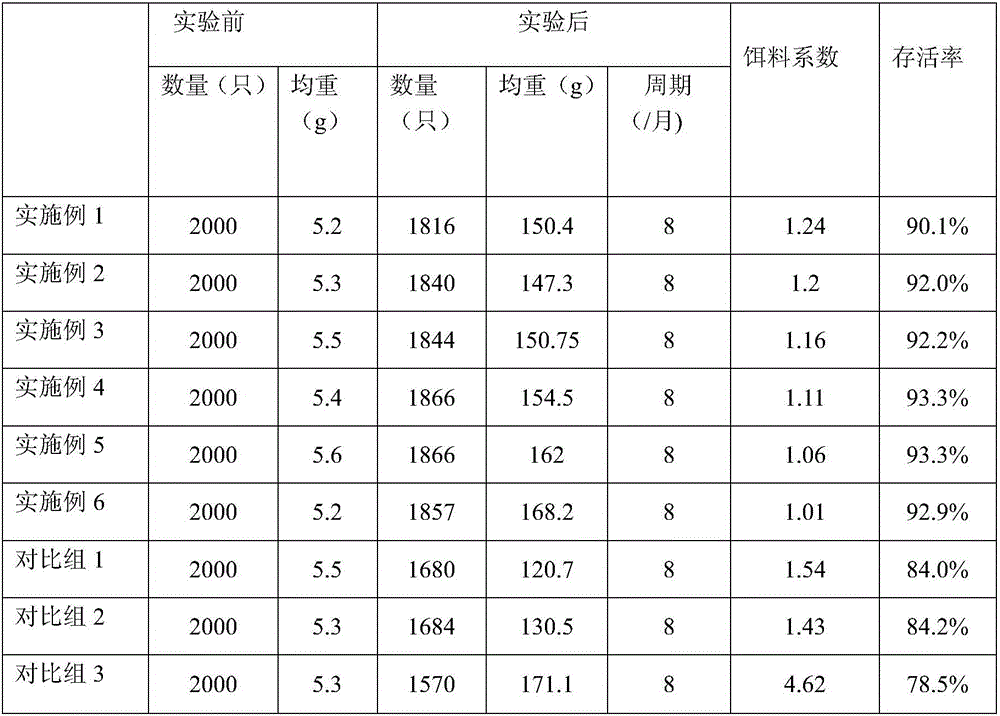

Examples

Embodiment 1

[0026] A high-efficiency and environment-friendly extruded compound feed for spiny frog, including the following raw material components in terms of mass percentage: 45% fish meal, 2% chicken meal, 2% spray-dried porcine blood globulin powder, 3% earthworm dry powder, fly maggot Dry powder 3%, fermented soybean meal 16%, flour 20%, soybean lecithin 1.5%, fish oil 3.5%, multivitamin 0.8%, multimineral 1.5%, 1.4%, choline chloride 0.24%, betaine 0.02%, 60% L-carnitine 0.02%, bile acid 0. calcium dihydrogen phosphate 01%, high temperature resistant phytase 0.01%.

[0027] After mixing all the raw materials of the above components, carry out superfine grinding, and the fineness of grinding to 98% of the material can pass through the 80-mesh screen; then the crushed material is placed in an extruder for granulation, the expansion temperature is 95°C, and the starch is gelatinized The density is greater than 90%, and the expansion coefficient is 1.70. The expanded pellets are produc...

Embodiment 2

[0029] A high-efficiency and environment-friendly extruded compound feed for spiny frog. The raw materials are formulated according to the following components: 28% fish meal, 6% chicken meal, 5% spray-dried porcine blood globulin powder, 3% earthworm dry powder, and 4% fly maggot dry powder , fermented soybean meal 25%, flour 20%, soybean lecithin 2%, fish oil 3%, multivitamin 0.8%, multimineral 1.5%, calcium dihydrogen phosphate 1.5%, choline chloride 0.15%, betaine 0.01%, 60 % L-carnitine 0.01%, bile acid 0.01%, high temperature resistant phytase 0.02%.

[0030] After mixing all the raw materials of the above components, carry out superfine grinding, and the material crushed to a fineness of 99% can pass through the 80-mesh sieve; then the crushed material is placed in an extruder for granulation, and the expansion temperature is 98°C, and the starch is gelatinized 1.0mm, 2.0mm, 3.0mm, 4.0mm and 5.0mm molds are used to produce different specifications and sizes of extruded ...

Embodiment 3

[0032] A high-efficiency and environment-friendly extruded compound feed for spiny frog. The raw materials are formulated according to the following components: 33% fish meal, 6% chicken meal, 2% spray-dried porcine blood globulin powder, 3% earthworm dry powder, and 4% fly maggot dry powder , fermented soybean meal 25%, flour 18%, soybean lecithin 2%, fish oil 3%, multivitamin 0.8%, multimineral 1.5%, calcium dihydrogen phosphate 1.5%, choline chloride 0.15%, betaine 0.01%, 60 % L-carnitine 0.01%, bile acid 0.01%, high temperature resistant phytase 0.02%.

[0033]After mixing all the raw materials of the above components, carry out superfine grinding, and the fineness of grinding to 98% of the material can pass through the 80-mesh sieve; then the crushed material is placed in an extruder for granulation, the expansion temperature is 100°C, and the starch is gelatinized The degree of expansion is greater than 90%, and the expansion coefficient is 1.70. 1.0mm, 2.0mm, 3.0mm, 4.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com