Tap fixture for tapping of milling machine

A technology for taps and milling machines, which is applied to manufacturing tools, thread trimmers, metal processing equipment, etc., can solve problems such as difficulty in operation, accuracy cannot meet technical requirements, tap breakage, etc., to ensure thread accuracy, controllable feed amount, Guaranteed effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

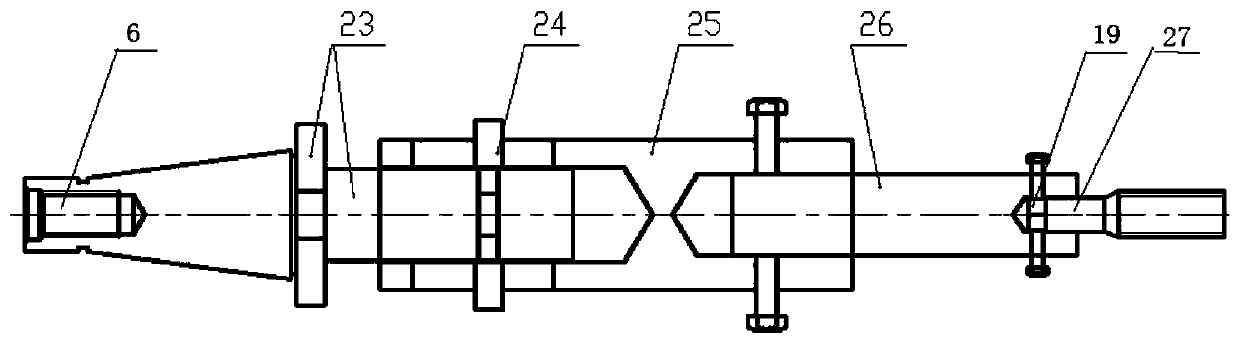

[0030] As shown in the accompanying drawings, a tap clamp for tapping of a milling machine includes a connecting head 23, a sliding sleeve 25, a collet 26, and a positioning pin 24. The taper shank 27 is assembled and connected, and the connecting head 23 and the collet 26 are assembled and connected through the sliding sleeve 25;

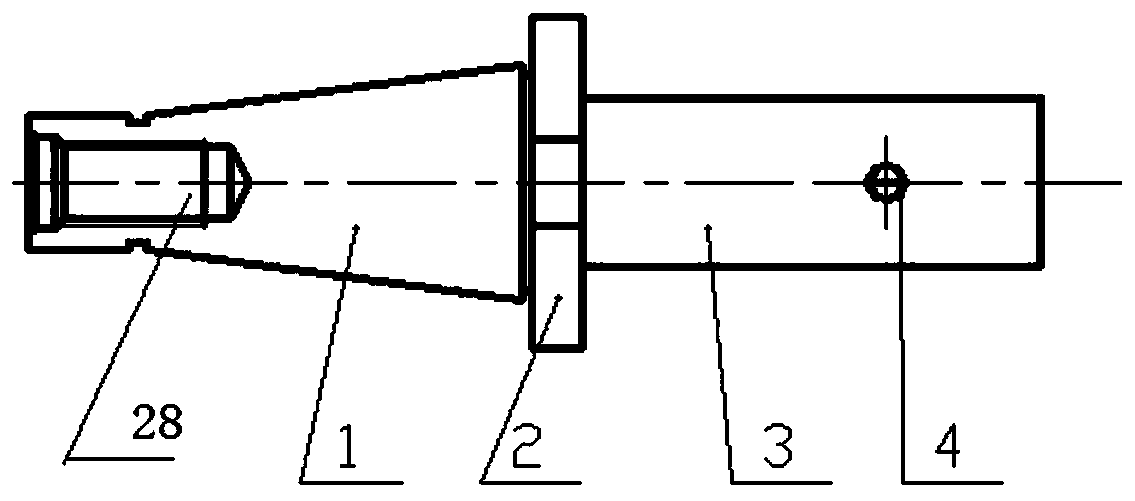

[0031] Described connecting head 23 comprises conical section 1, chuck 2, guide rod 3, and conical section 1, guide rod 3 are respectively positioned at chuck 2 both sides, and the end face of conical section 1 is provided with machine head assembly hole 28, and machine head The assembly hole 28 is matched with the milling machine head 27, and the guide rod 3 is provided with a first threaded hole 4;

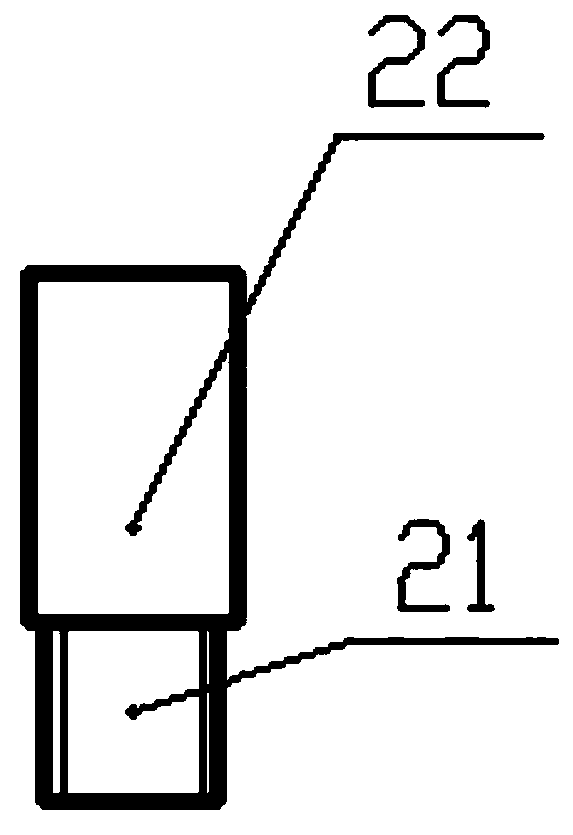

[0032] The sliding sleeve 25 is a cylindrical shaft sleeve, and the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com