Wall printing device based on computer processing

A computer processing and printing technology, applied in the field of image processing, can solve the problems of poor quality of printing effect, inconvenient printing on high walls, low efficiency of artificial paint, etc., and achieves changeable printing work, good printing effect and cutting quantity. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

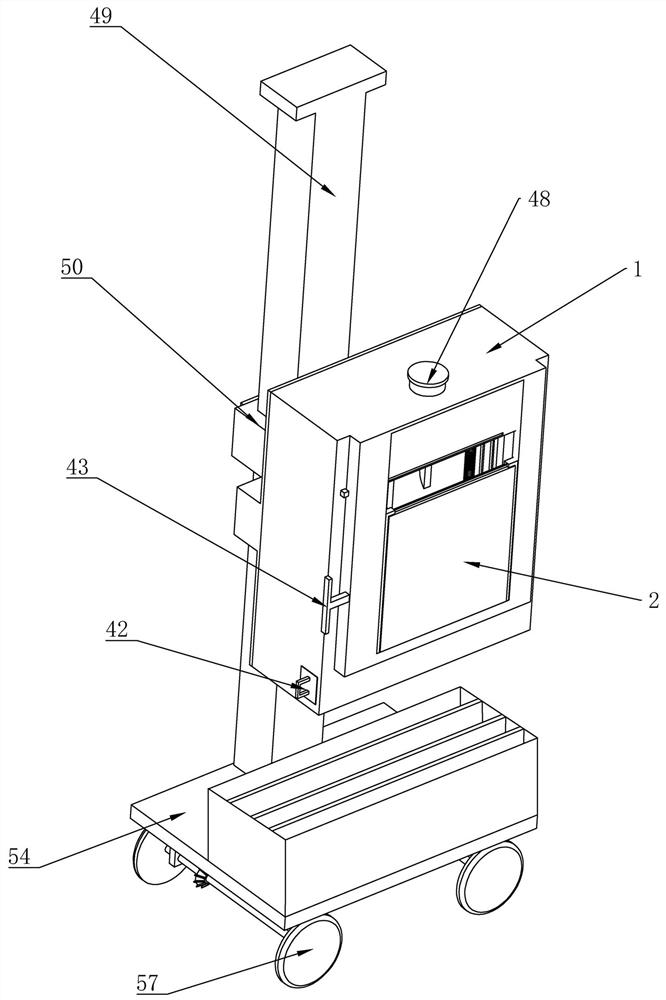

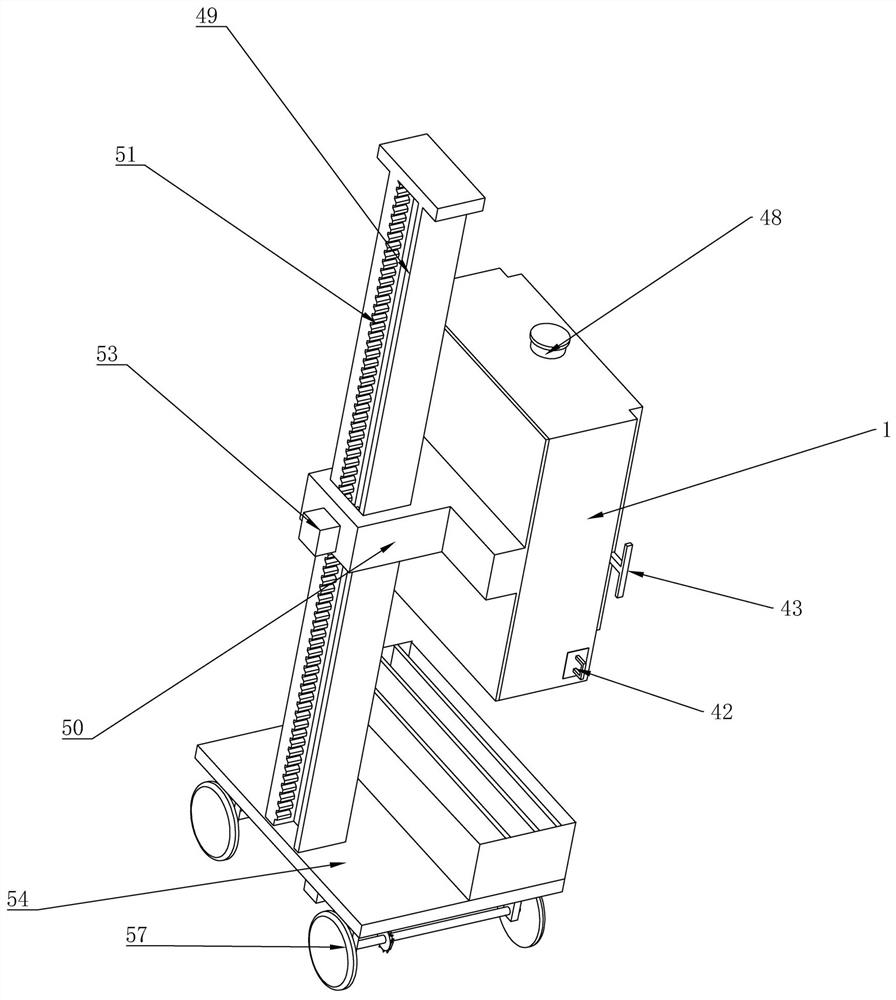

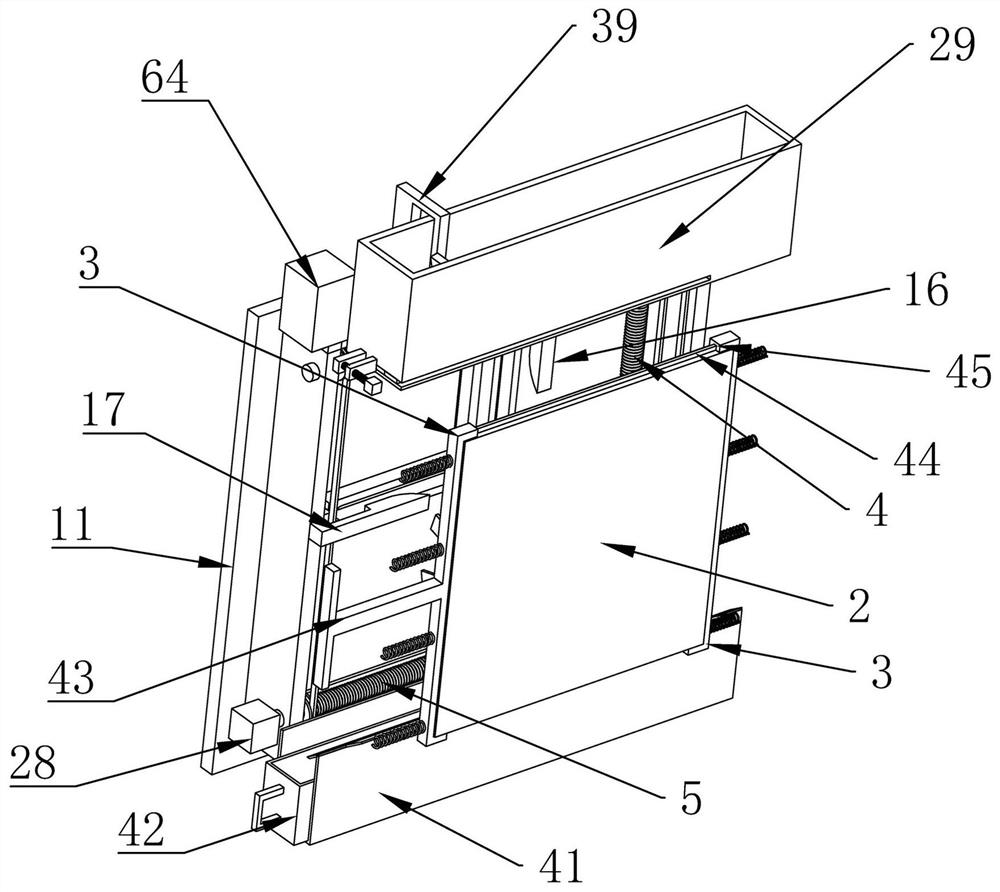

[0048] Embodiment 1, the present invention is a wall printing device based on computer processing, which is characterized in that it includes a printing cabinet 1, and a silk screen board 2 is slidably connected to one side of the printing cabinet 1, and the screen board 2 is detachably connected to the printing cabinet. On the cabinet 1, the silk screen board 2 can be freely replaced according to the needs of customers to realize the printing of different patterns. The two sides of the screen board 2 are contacted and connected with a fixing frame 3 that is slidably connected to the printing cabinet 1. The frame 3 can fix the screen plate 2, and by pulling the fixing frames 3 on both sides, the screen plate 2 can be taken out and put in and the screen plate 2 can be fixed. There is a lifting reciprocating screw rod 4, the upper and lower ends of the printing cabinet 1 are rotationally connected with a translational reciprocating screw rod 5, and the two lifting and reciprocati...

Embodiment 2

[0052] Embodiment 2, on the basis of Embodiment 1, the end of the upper scraper 9 and the lower scraper 10 away from the screen plate 2 are provided with jacking grooves 15, and the upper and lower ends of the printing cabinet 1 are Both are fixedly connected with the first stop rod 16, and the left and right sides of the printing cabinet 1 are fixedly connected with the second stop rod 17, the first stop rod 16, the second stop rod 17 are all slidably connected in the jacking groove 15, when the first limiting rod 16 and the second limiting rod 17 touch the jacking groove 15, the upper scraper 9 or the lower scraper 10 will be lifted up, and the coating Flow out along the screen plate 2 to prepare for the next coating. By setting a gap on the side of the jacking groove 15 through which the first stop bar 16 and the second stop bar 17 can pass, it can be ensured that when the printing frame 8 when rising, when the printing frame 8 moves to the top, the first limit rod 16 locat...

Embodiment 3

[0056] Embodiment three, on the basis of embodiment two, the top of the screen plate 2 is provided with a feed tank 29 fixedly connected to the printing cabinet 1, the feed tank 29 is filled with paint, and the The bottom of the feeding trough 29 is provided with a feeding port 30, and the feeding port 30 is located above the upper scraper 9. When the paint flows out along the feeding port 30, the paint can fall on the upper scraper 9 without falling out of the upper scraper. Plate 9, the described feeding port 30 is provided with a quantitative plate 31 that is slidably connected in the feeding chute 29, the sliding of the quantitative plate 31 can control the opening size of the feeding port 30, and one side of the quantitative plate 31 is rotatably connected There is an adjusting screw 32, and one side of the feeding chute 29 is fixedly connected with an adjusting fixing plate 33, and the adjusting screw 32 runs through the adjusting fixing plate 33 and is threadedly matched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com