Preparation method for p-aminodiphenylamine

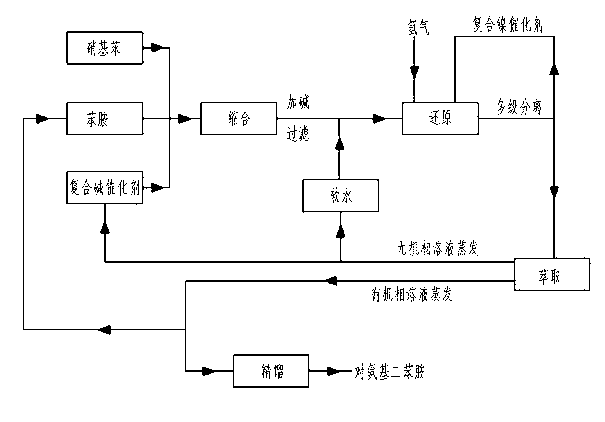

A technology for p-aminodiphenylamine and aniline, which is applied in the field of industrial preparation of p-aminodiphenylamine, and can solve problems such as catalyst activation, complex operating units in the separation process, increased risk of reduction and post-processing units, increased equipment investment and operating costs, etc. , to achieve the effect of accurate and flexible adding operation, reducing labor intensity, and simplifying the separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

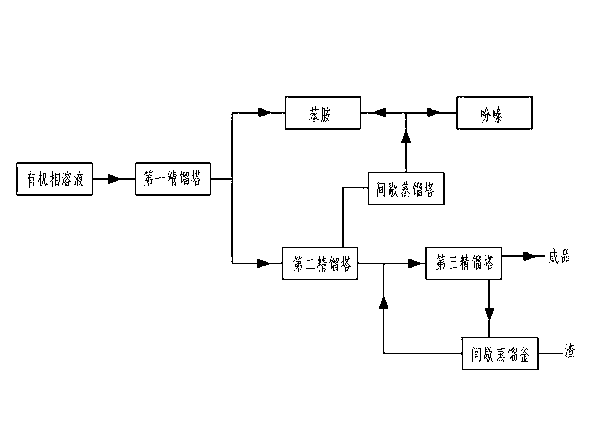

Method used

Image

Examples

Embodiment 1

[0052] condensation reaction

[0053] The condensation reaction is to keep the vacuum degree of the reaction system at -0.09MPa, adjust the feed amount of raw materials to be 9L / hr of aniline, 3L / hr of nitrobenzene, and 10L / hr of composite alkali catalyst, and enter the primary condensation reaction kettle. Use the circulating pump at the bottom of the tank to carry out heating and dehydration reaction in the condensation liquid evaporator. The condensation liquid evaporator uses isopropanol as the heat medium. After heating and vaporizing the isopropanol with low-pressure steam, the condensation liquid entering the evaporator is circulated and heated. The cooling water removed by vacuum contains a small amount of aniline and enters the aniline water storage tank. The reaction temperature is controlled at 80°C, and the circulation flow rate is controlled at 400L / hr. After the liquid level in the primary condensation tank reaches a certain level, it enters the secondary tank or...

Embodiment 2

[0071] A preparation method of p-aminodiphenylamine, carried out according to the following steps:

[0072] first step, condensation

[0073] Pass nitrobenzene, aniline and composite base catalyst into the reaction kettle for condensation reaction to generate condensation liquid;

[0074] The weight percentage concentration of described composite base catalyst is 25%; The volume ratio of described nitrobenzene, aniline and composite base catalyst is 1: 8: 8;

[0075] The condensation reaction conditions are as follows: the reaction temperature is 85°C, the reaction time is 3 hours, and the reaction pressure is -0.090~-0.098MPa;

[0076] The second step is to add alkali to form a salt

[0077] Add solid caustic soda to the condensed liquid, then stir and filter to obtain a qualified condensed liquid; the stirring time for salt formation is 1 hour, and the CO in the qualified condensed liquid 3 -2 The weight percentage content is 0.3%, and the salt-forming temperature is 60°...

Embodiment 3

[0094] A preparation method of p-aminodiphenylamine, carried out according to the following steps:

[0095] first step, condensation

[0096] Pass nitrobenzene, aniline and composite base catalyst into the reaction kettle for condensation reaction to generate condensation liquid;

[0097] The weight percent concentration of described composite base catalyst is 25%; The volume ratio of described nitrobenzene, aniline and composite base catalyst is 1:4:3;

[0098] The condensation reaction conditions are as follows: the reaction temperature is 55°C, the reaction time is 2 hours, and the reaction pressure is -0.090~-0.098MPa;

[0099] The second step is to add alkali to form a salt

[0100] Add solid caustic soda to the condensed liquid, then stir and filter to obtain a qualified condensed liquid; the stirring time for salt formation is 1 hour, and the CO in the qualified condensed liquid 3 -2 The weight percentage content is 0.1%, and the salt-forming temperature is 60°C;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com