Patents

Literature

46 results about "P-aminodiphenylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

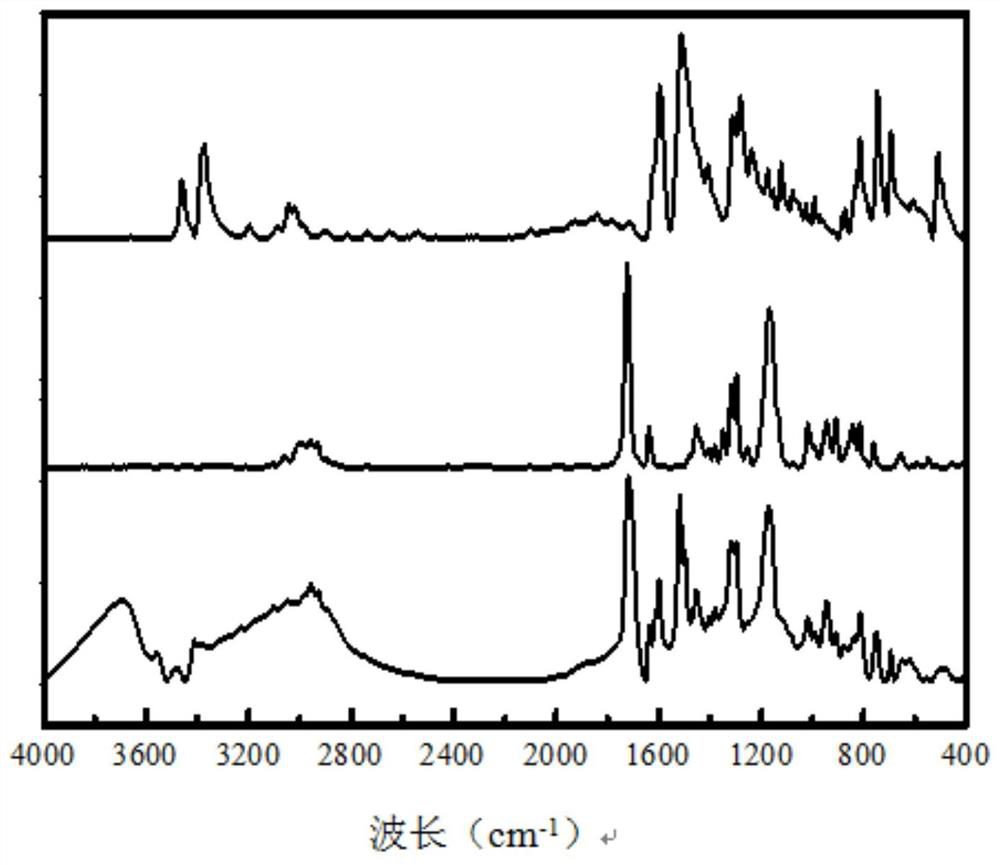

Silane coupling agent and preparation method thereof

InactiveCN102584886AHas anti-aging functionSimple manufacturing methodGroup 4/14 element organic compoundsSilanesNitrogen

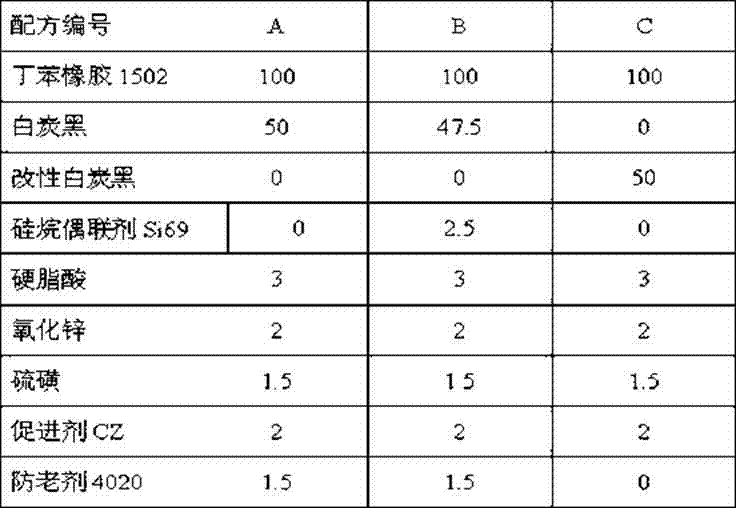

The invention discloses a silane coupling agent and a preparation method thereof. The method comprises the steps of: mixing a coupling agent (gamma-glycidyl ether oxopropyl trimethoxy-silane) and aminophenol p-diphenylamine (PPDA) according to a certain molar ratio; before temperature raising and heating, introducing nitrogen till the end of reaction, and continuously reacting for a period of time under the condition of magnetic force stirring, thus obtaining the silane coupling agent. The prepared silane coupling agent can be used for inorganic filler such as white carbon black and argil; compared with white carbon black modified with the common silane coupling agent, white carbon black modified with the silane coupling agent disclosed by the invention has an excellent aging-preventing function besides the enhancement of the compatibility between the filler and plastic matrixes, and thus the service life of mad products can be prolonged; and when applied to butylbenzene and hevea rubber, the silane coupling agent has excellent performance superior to 2-(gamma-( triethoxy) propyl group) tetrasulfide, so the silane coupling agent can completely replace the 2-(gamma-( triethoxy) propyl group) tetrasulfide to be applied to some rubber.

Owner:SOUTH CHINA UNIV OF TECH

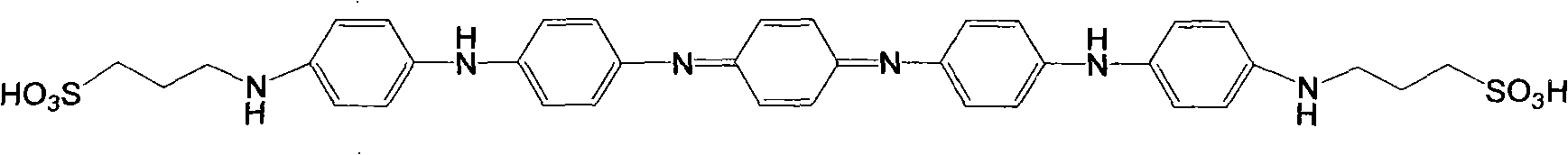

Water-soluble self-doping aniline oligomer and preparation method thereof

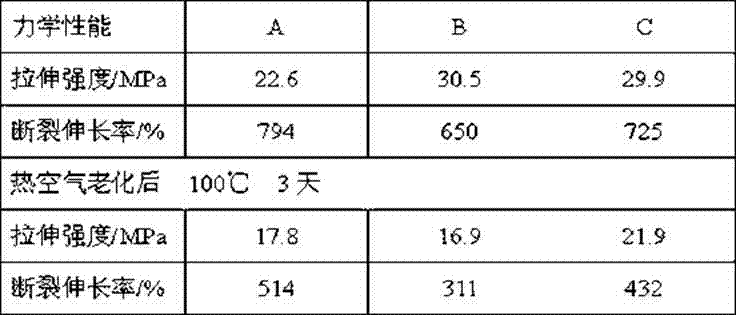

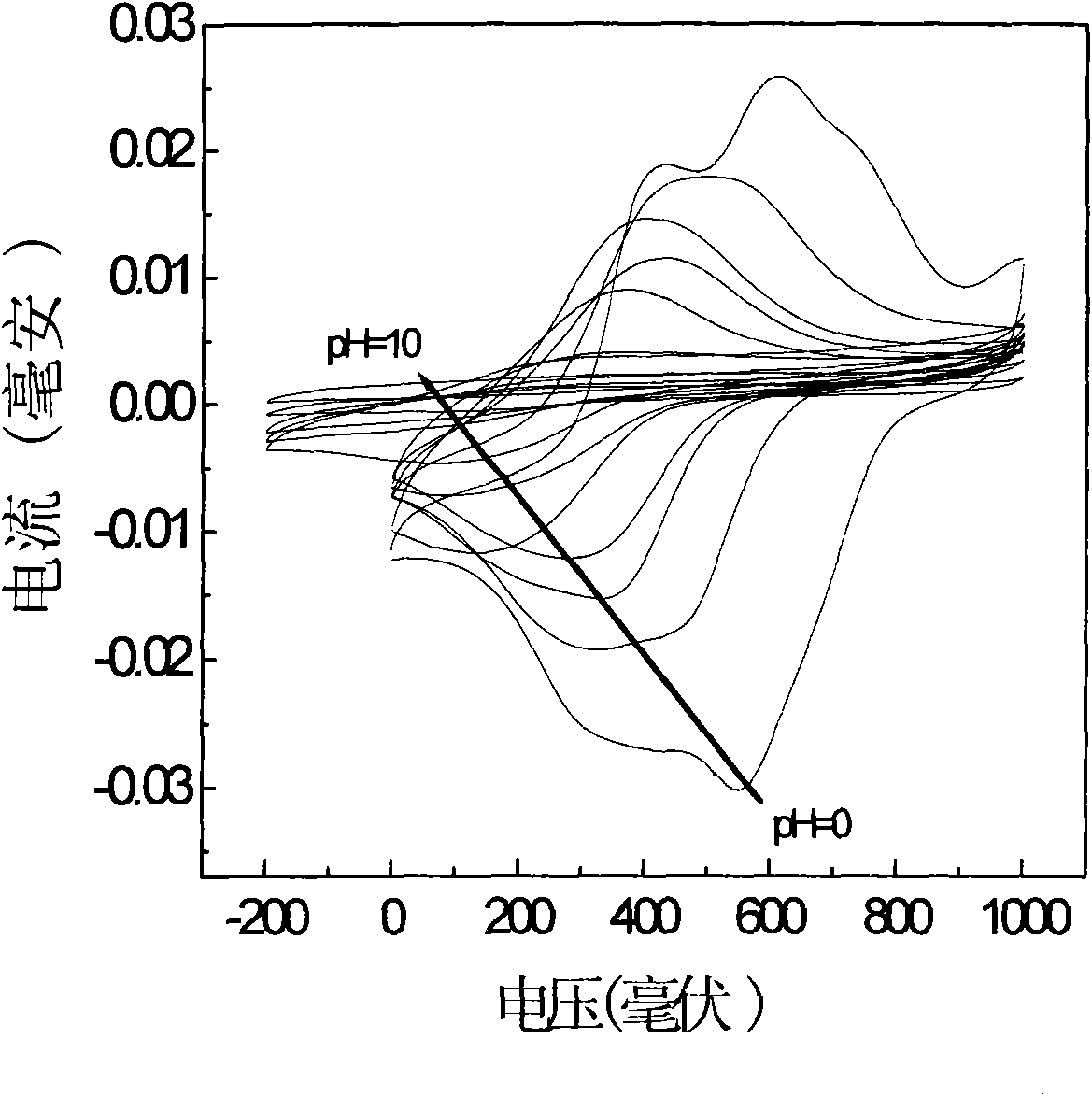

The invention belongs to the field of functional materials, in particular to a novel aniline oligomer with water solubility and self-doping character and a preparation method thereof. The aniline oligomer is prepared by the preoxidation coupling reaction of p-phenylenediamine and a monomer which is obtained by the reaction of p-aminodiphenylamine and propane sultone. The invention is characterized in that the synthesis route is simple, the reaction condition is mild, and the operation is convenient. The synthesized aniline oligomer has good dissolubility in water, and simultaneously, the existence of sulfonic groups at the two ends enables the aniline oligomer to have the self-doping character and show certain electrochemical activity in acid, neutral or even alkaline environment. The water-soluble aniline oligomer has great application potency in terms of metal corrosion inhibition.

Owner:JILIN UNIV

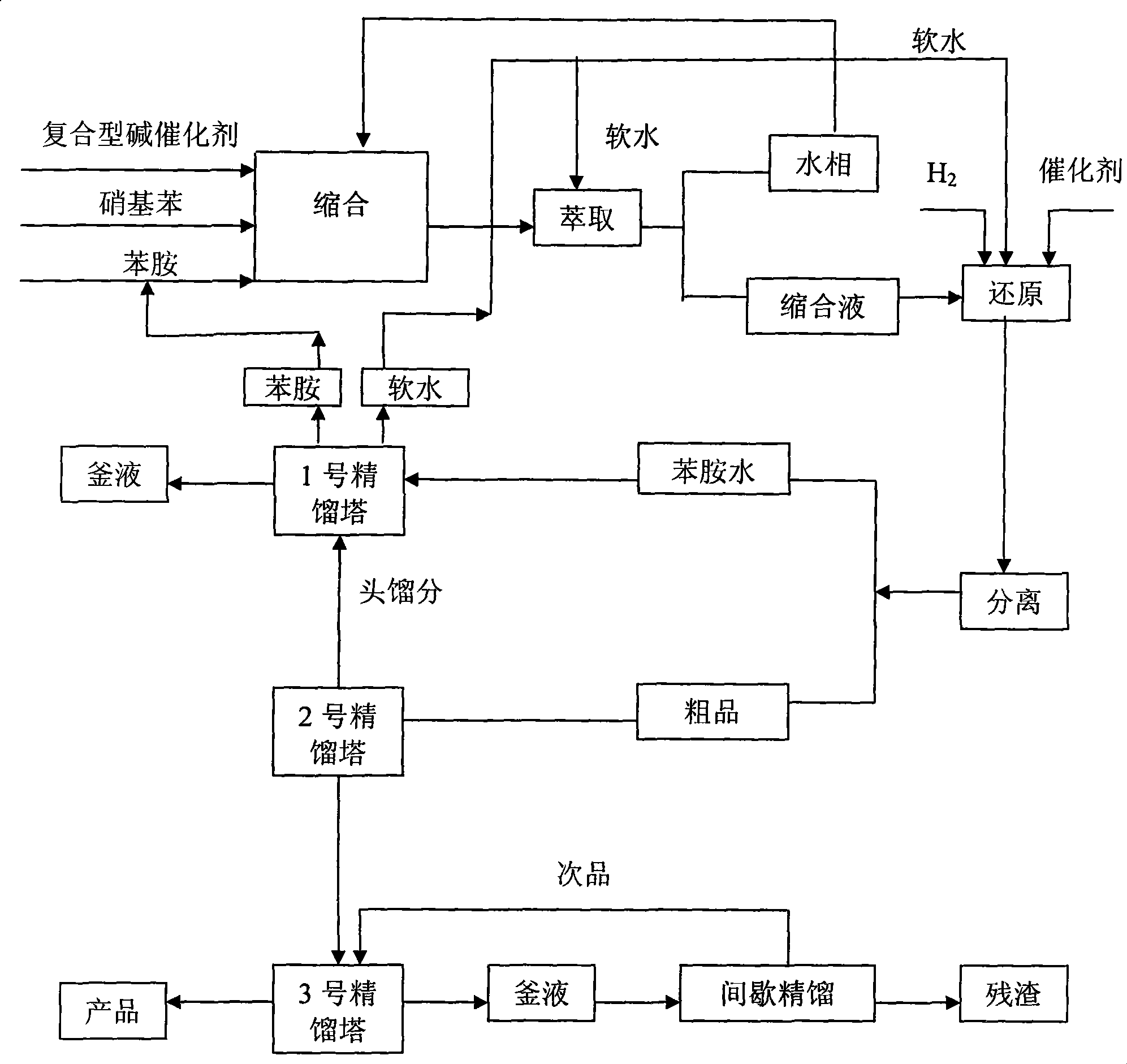

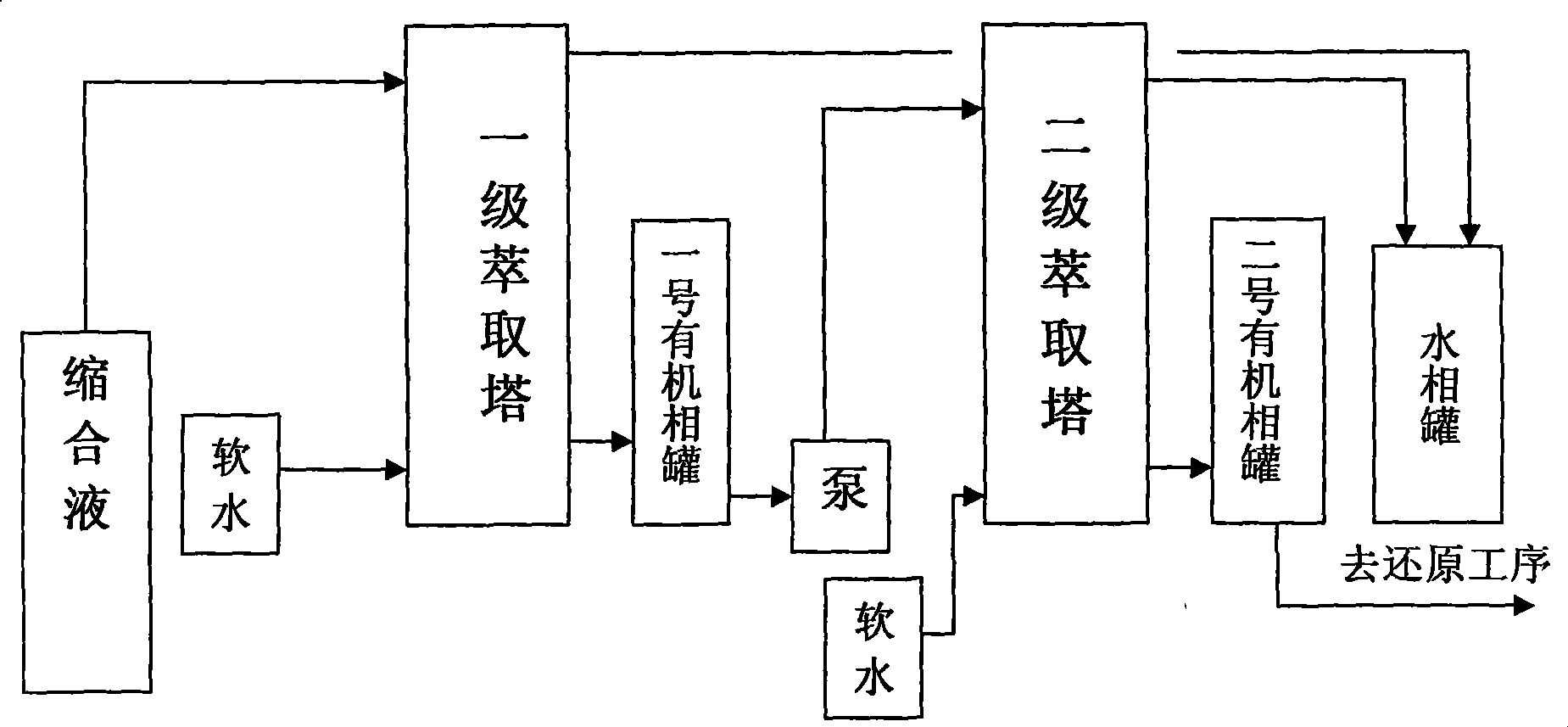

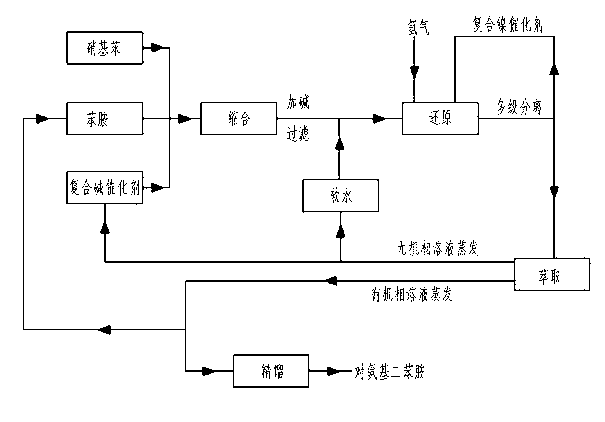

Preparation method of p-aminodiphenylamine

ActiveCN101381315ALow priceReduce manufacturing costOrganic compound preparationAmino compound preparation by condensation/addition reactionsHydrogenNitrobenzene

The invention relates to a method for preparing p-aminodiphenylamine, which comprises the following: (1) a step of condensation, in which, nitrobenzene and aniline produce condensation reaction in the presence of a catalyst to generate condensation solution including 4-nitrodiphenylamine and 4-nitrosodiphenylamine; (2) a step of extraction, in which, water phase and organic phase in the condensation solution are separated by an extracting method; (3) a step of reduction, in which, hydrogen and the organic phase of the condensation solution produce reduction reaction in the presence of the catalyst to generate reduction solution including the p-aminodiphenylamine; (4) a step of separation, in which, the p-aminodiphenylamine is separated from the reduction solution to form crude p-aminodiphenylamine feed liquid; and (5) a step of rectification, in which, the p-aminodiphenylamine is separated from the crude p-aminodiphenylamine feed liquid in a rectification mode to form a p-aminodiphenylamine product. The method is suitable for serialized industrialized production in large scale, and has the advantages of low reduction reaction temperature, mild reaction condition, few side products, high conversion rate and selection, low labor intensity and no corrosive liquid, thereby reducing pollution to environment.

Owner:张国柱

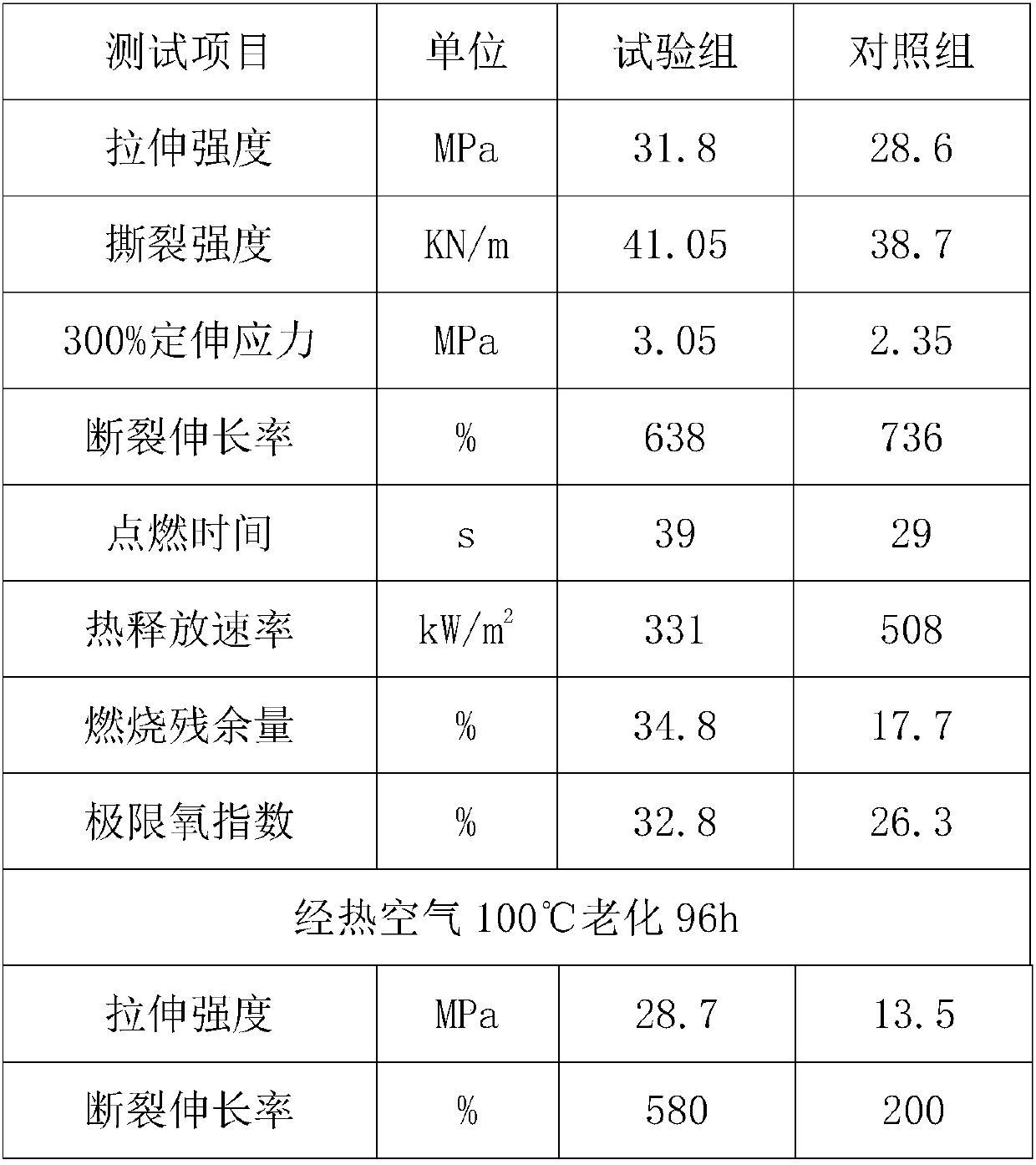

High-strength and anti-impacting natural rubber cable sheathing material

ActiveCN106117644AHigh strengthGood compatibilityInsulated cablesInsulated conductorsLow-density polyethylenePolymer science

The invention discloses a high-strength and anti-impacting natural rubber cable sheathing material. The high-strength and anti-impacting natural rubber cable sheathing material is prepared from the following raw materials: natural rubber, polyvinyl chloride, low-density polyethylene, an ethylene-vinyl acetate copolymer, zinc oxide, stearic acid, sulfur, high-abrasion-resisting furnace black, carbon nanotubes, nano calcium carbonate, montmorillonoid, zirconium diboride, calcium sulfate whiskers, lignocellulose short fibers, cotton short fibers, an accelerant M, an accelerant BZ, a poly-3-hydroxybutyrate-4-hydroxybutyrate, epoxy soybean oil, an anti-aging agent RD, an anti-aging agent MB, p-aminodiphenyl amine, gamma-epoxypropoxy propyltrimethoxysilicane and vinyltriethoxysilane. The high-strength and anti-impacting natural rubber cable sheathing material disclosed by the invention is high in strength, good in anti-impacting performance, excellent in anti-aging performance and long in service life.

Owner:ANHUI ELECTRIC GRP SHARES

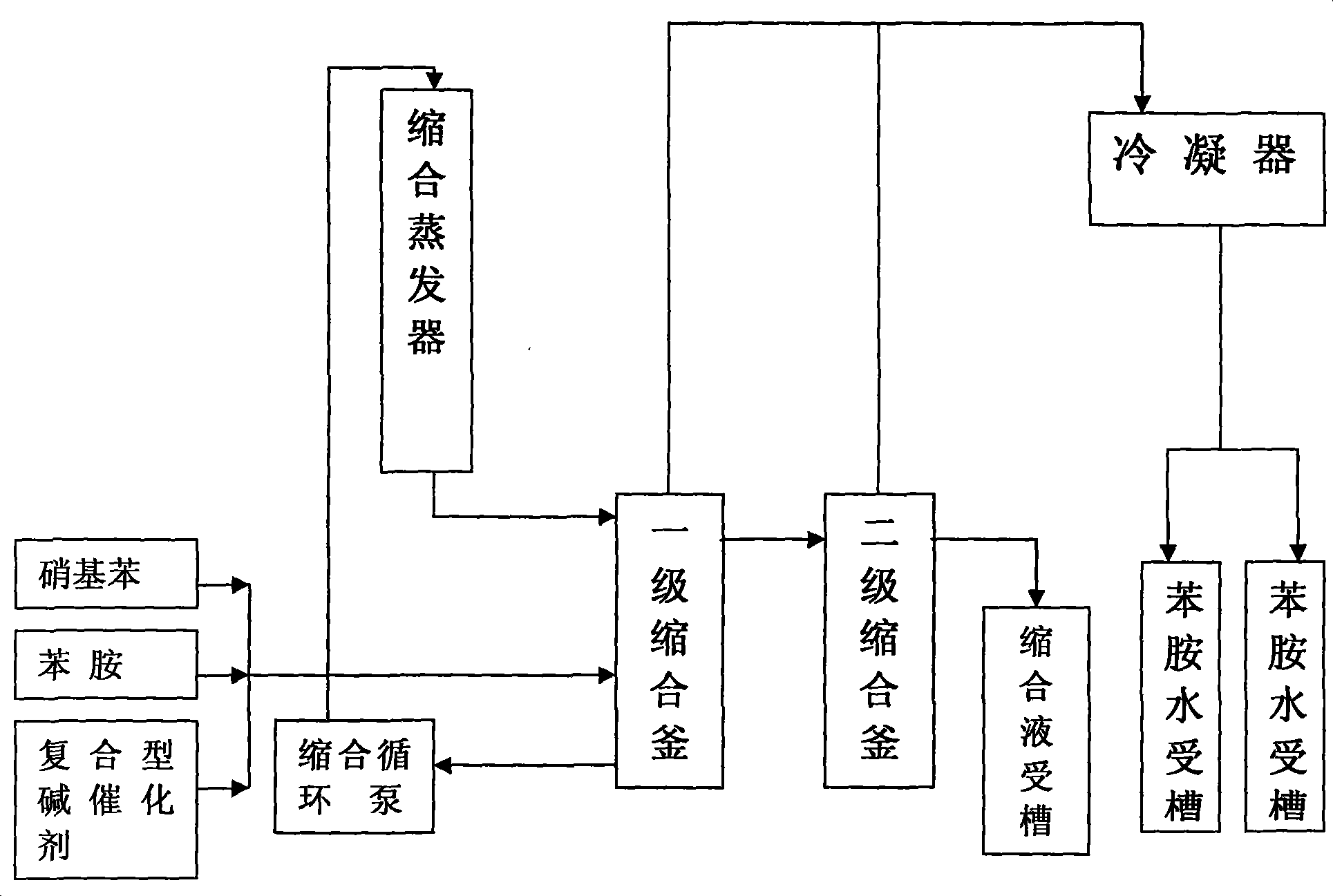

Preparation method for p-aminodiphenylamine

InactiveCN102796011AImprove continuityReduce operating unitAmino compound purification/separationOrganic compound preparationNickel catalystHydrogen

The invention relates to a preparation method for p-aminodiphenylamine, and belongs to the technical field of industrial preparation for p-aminodiphenylamine. The technical problem to-be-solved is to provide a preparation method for p-aminodiphenylamine with a condensation reaction catalyst capable of being activated and reused and a reduction reaction solvent having no danger and being easily separated. The technical solution adopted includes: a first step of feeding nitrobenzene, aniline and a complex alkali catalyst into a reactor for a condensation reaction to generate a condensation liquid; a second step of adding alkali to form salt to get a qualified condensation liquid; a third step of adding soft water and composite nickel catalyst slurry, and feeding hydrogen to perform a reduction reaction to get a reduction liquid; a fourth step of extracting and distilling the reduction liquid to get a rectification raw material; and a fifth step of performing a multi-stage rectification for the rectification raw material to get the finished p-aminodiphenylamine. The method can be widely applied to the field of p-aminodiphenylamine preparation.

Owner:山西翔宇化工有限公司

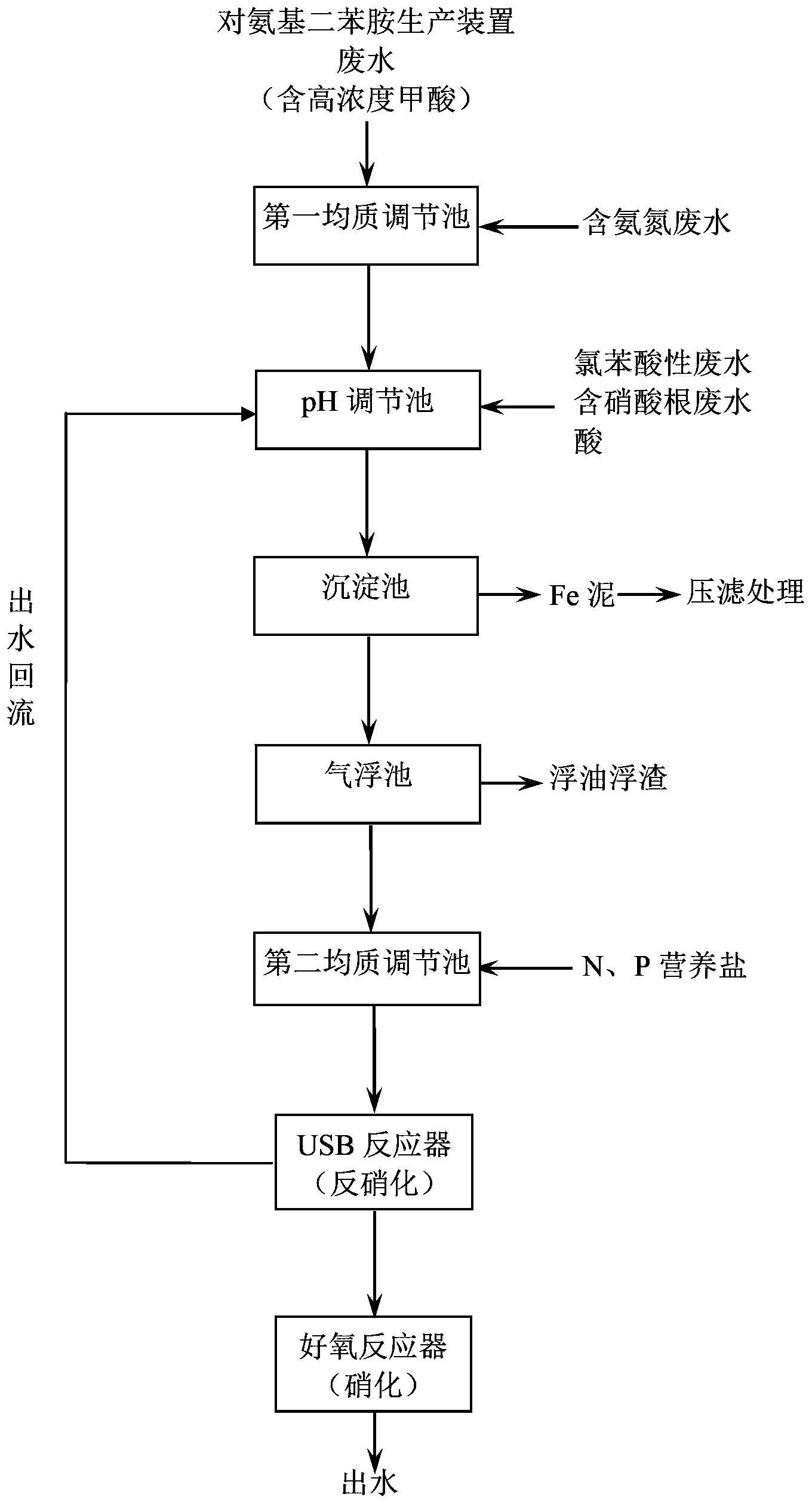

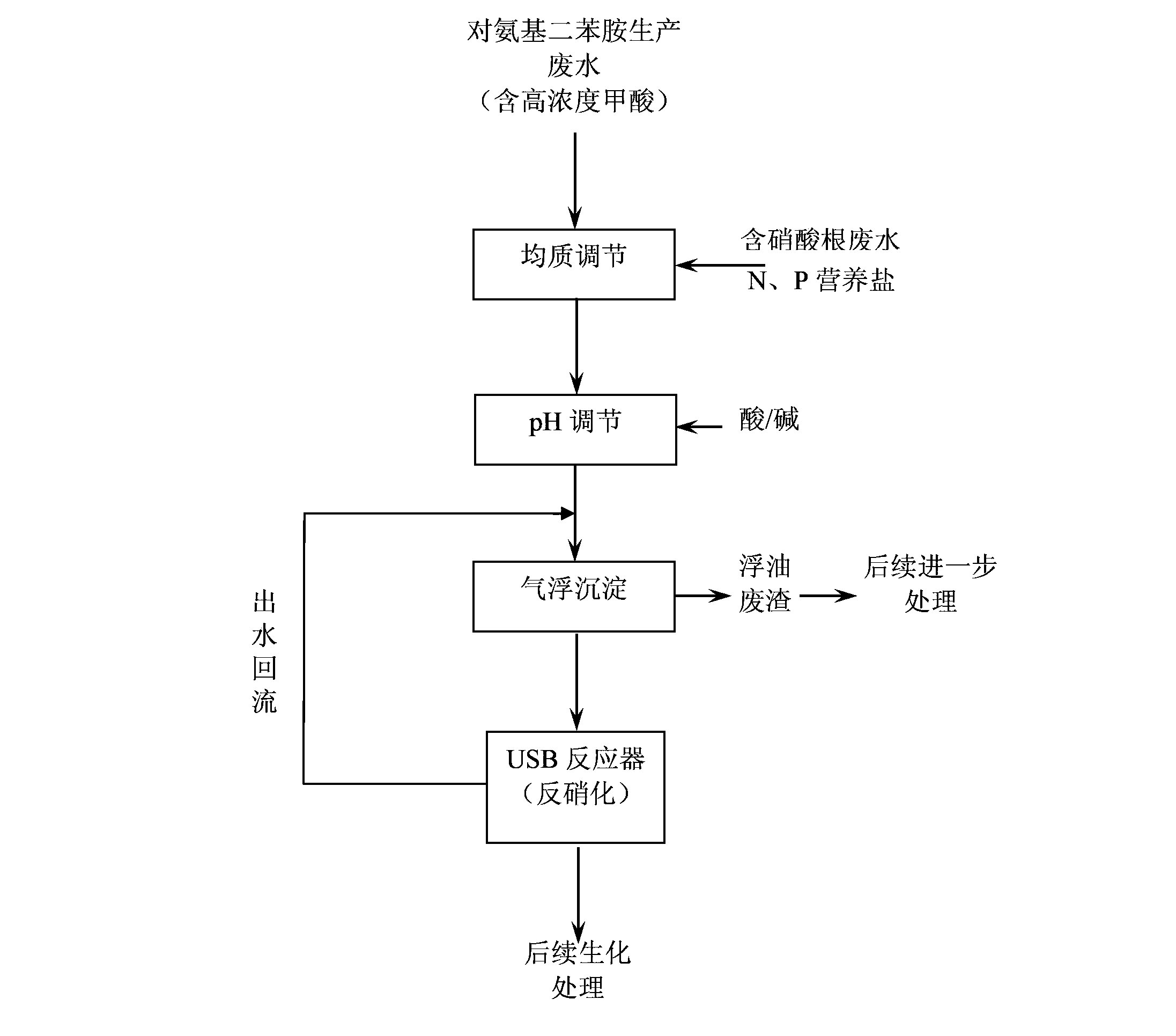

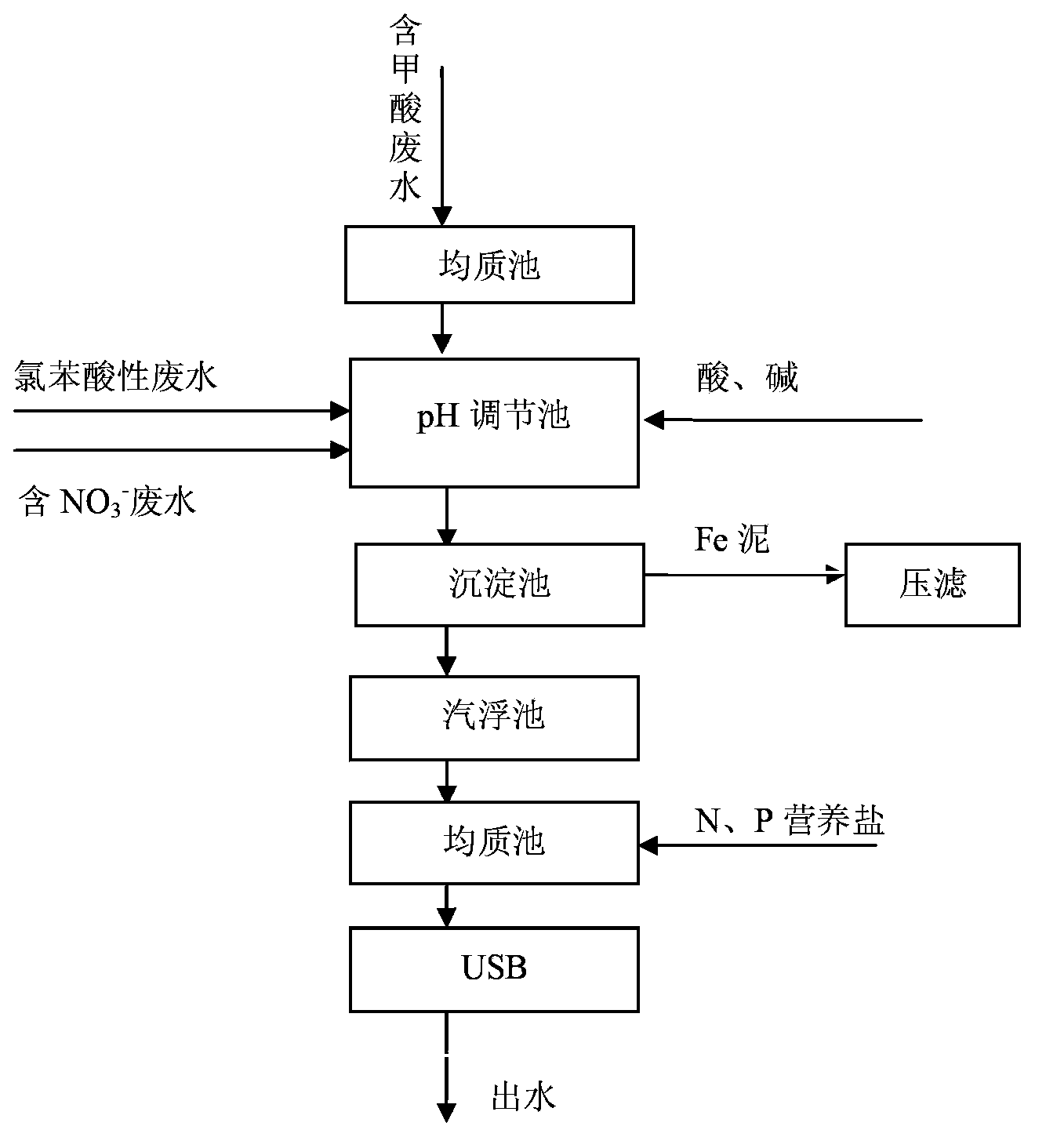

Method for treating ammonia-nitrogen containing p-aminodiphenyl amine production wastewater

ActiveCN104250053AImprove removal efficiencyHigh volume loadMultistage water/sewage treatmentNature of treatment waterHigh concentrationNitration

The invention relates to a method for treating ammonia-nitrogen containing p-aminodiphenyl amine production wastewater. The method comprises the steps: firstly, mixing and homogenizing the p-aminodiphenyl amine production wastewater and phenylamine production wastewater; then allowing the wastewater to enter a pH regulation tank, successively adding Fe-containing chlorobenzene acidic wastewater, a nitrate-containing solution or wastewater, alkaline denitrification backflow water and dilution water, and finally, adding an acid to adjust the pH value; allowing Fe in the mixed wastewater to form a flocculant Fe(OH)3, and carrying out precipitation treatment; then further removing impurities in an air flotation tank; allowing effluent in the air flotation tank to enter a homogeneous adjusting tank, and adding N and P nutritive salts; finally, removing high-concentration organic compounds in the wastewater through a denitrification reaction; and carrying out a nitration reaction by using the alkalinity generated in the denitrification process to remove ammonia nitrogen in the wastewater, and reaching standards to discharge. The treatment method has the advantages of less investment, high income, simple operation, and stable treatment effect; and the produced wastewater can be further treated and utilized, not only is the purpose of reducing wastewater emissions achieved, but also economic benefits are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

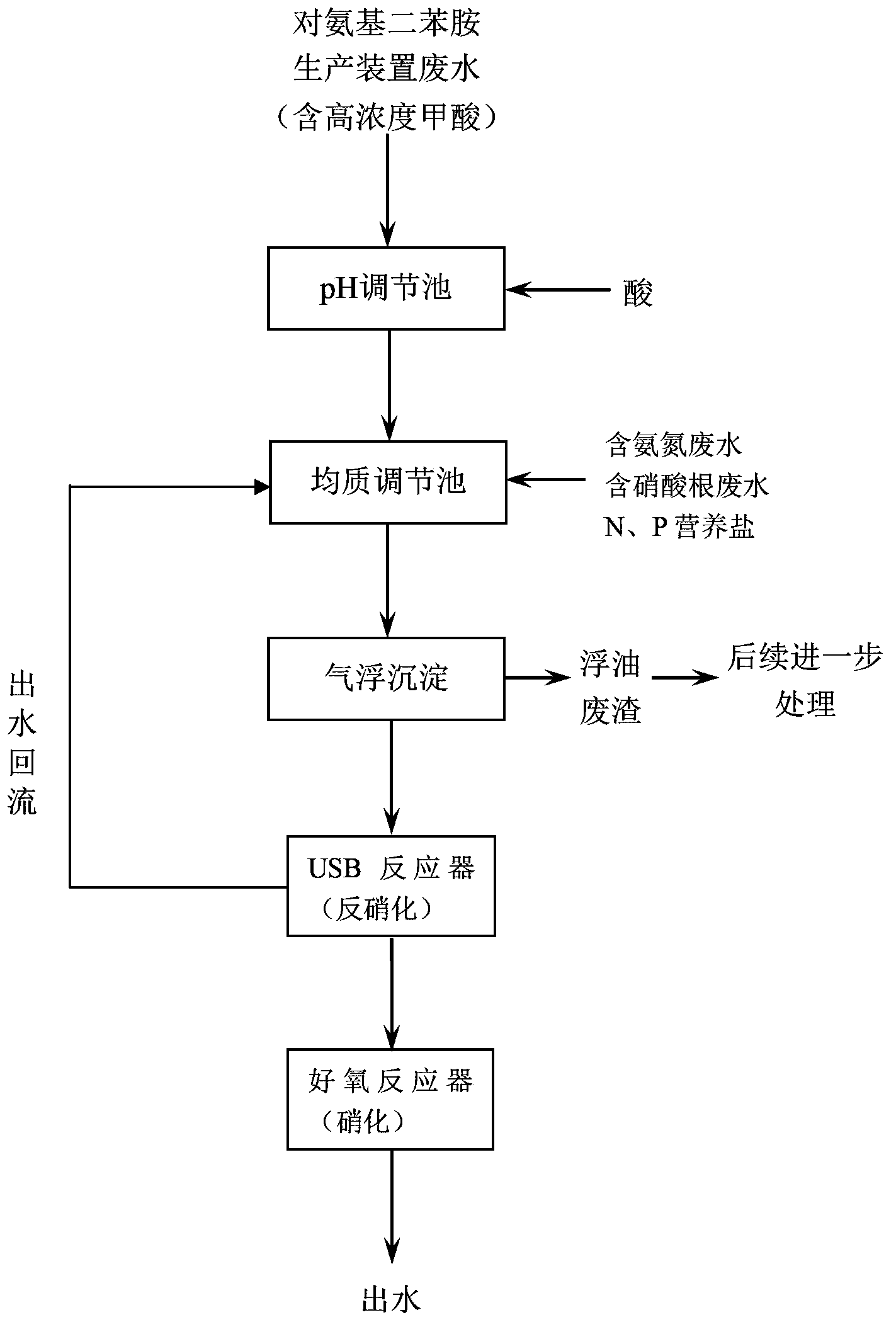

Method for treating ammonia-nitrogen containing p-aminodiphenyl amine production wastewater

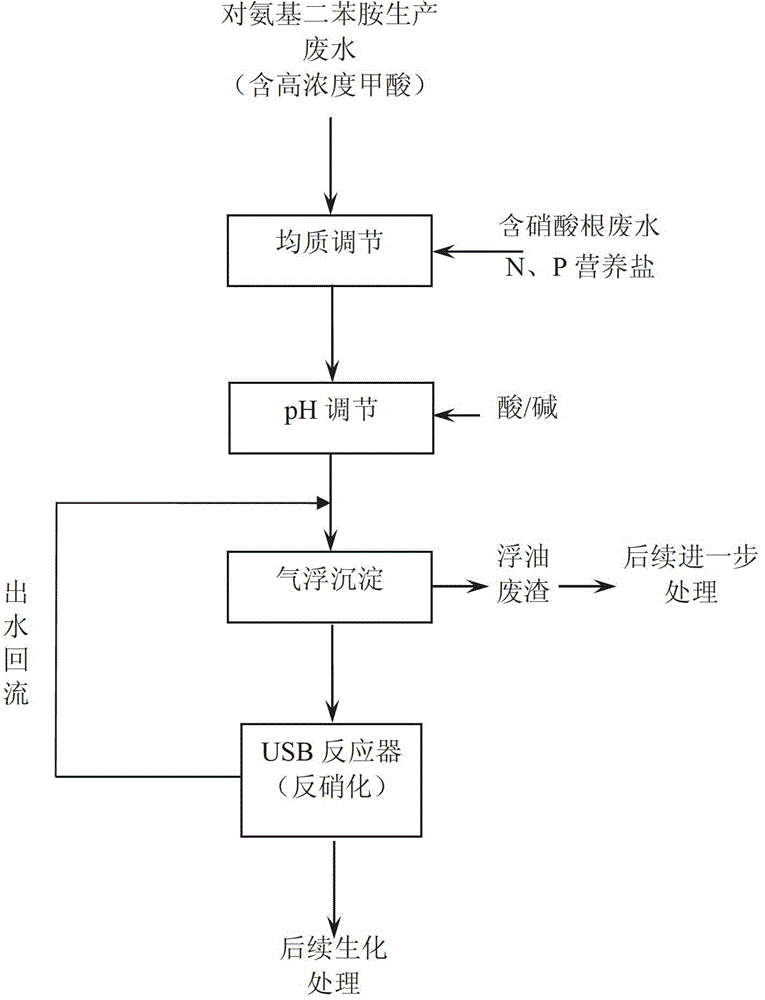

ActiveCN104250052AImprove removal efficiencyHigh volume loadWater contaminantsMultistage water/sewage treatmentHigh concentrationAlkalinity

The invention relates to a method for treating ammonia-nitrogen containing p-aminodiphenyl amine production wastewater. The method comprises the steps: carrying out pH adjustment on the p-aminodiphenyl amine production wastewater, mixing and homogenizing with phenylamine production wastewater, then adding nitrate-containing wastewater into a homogeneous adjusting tank, completing adjustment of the C / N ratio and the pH value of the mixed wastewater in the homogeneous adjusting tank, next adding N and P nutritive salts into the homogeneous adjusting tank, if effluent of the homogeneous adjusting tank contains more waste residue quantity, requiring to carry out precipitate air flotation treatment on the effluent of the homogeneous adjusting tank, then removing high-concentration organic matters contained in the effluent of the homogeneous adjusting tank through a denitrification reaction, and finally, carrying out a nitration reaction by using the alkalinity generated by the denitrification process to remove ammonia nitrogen in the denitrification reaction effluent. The wastewater treatment method can effectively reduce the organic matters and ammonia nitrogen in the wastewater, substantially cuts down the total amount of pollutants discharged to the environment by a p-aminodiphenyl amine production device, and makes the wastewater reach standards and discharged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-aging natural rubber synthesis method

The invention belongs to the technical field of rubber materials, and relates to an anti-aging natural rubber synthesis method, which comprises: (1) synthesizing an anti-aging silane coupling agent: adding gamma-glycidyl ether propyltrimethoxysilane and p-aminodiphenylamine to a reaction kettle, introducing 0.2-0.6 MPa nitrogen, heating to a temperature of 120-150 DEG C, and stirring for 1-1.5 h at a stirring rotation speed of 100-120 r / min to obtain anti-aging silane coupling agent; and (2) preparing an in-situ modified filler: weighing carbon black, white carbon black and an anti-aging silane coupling agent, placing into the reaction kettle, introducing 0.1-0.2 MPa N2 gas, carrying out heating to a temperature of 50-60 DEG C, and stirring for 1-1.5 h at a stirring rotation speed of 100-120 r / min to prepare the in-situ modified filler. According to the present invention, with the preparation method, the anti-aging natural rubber is prepared by adding the anti-aging coupling agent modified filler, such that the aging resistance of the rubber is improved, and the operation is simple; and the prepared anti-aging rubber has advantages of high strength, strong aging resistance and thelike.

Owner:SHENYANG SAIYA RUBBER PRODS

Method for recovering, treating and recycling quaternary ammonium base

InactiveCN108623475AReduce viscosityImprove liquidityAmino compound purification/separationOrganic matterSolvent

The invention discloses a method for recovering, treating and recycling quaternary ammonium base. According to the invention, the method overcomes disadvantages in conventional recovery and treatmentof quaternary ammonium base produced in preparation of p-aminodiphenylamine by using a nitrobenzene process; the method of the invention has an extra procedure of solvent extraction and recovery of p-aminodiphenylamine and macromolecular viscous organic substances in the quaternary ammonium base, thereby lowering the content of p-aminodiphenylamine and macromolecular viscous organic matters in theammonium base, reducing the viscosity of the recovered quaternary ammonium base, decreasing difficulties in desalting filtering of the recovered quaternary ammonium base, improving desalting effect on the recovered quaternary ammonium base and promoting normal implementation of subsequent condensation reactions and reduction reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

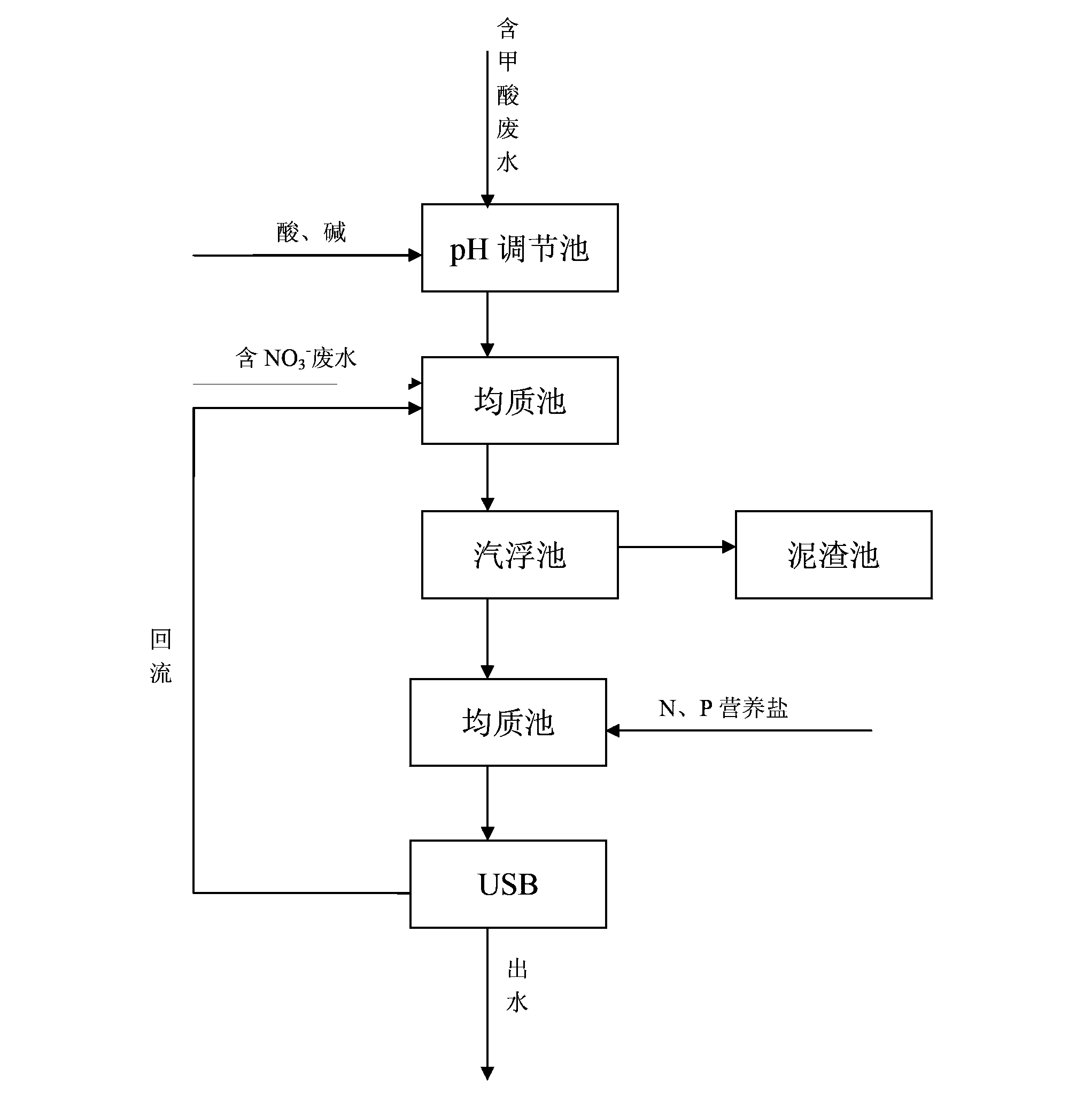

Method for accumulating nitrite nitrogen by performing short-cut denitrification on p-aminodiphenyl amine production wastewater

ActiveCN103663846AReduce contentImprove removal efficiencyMultistage water/sewage treatmentHigh concentrationTreatment effect

The invention provides a method for accumulating nitrite nitrogen by performing short-cut denitrification on p-aminodiphenyl amine production wastewater. The method comprises the following steps of: mixing formic acid-containing wastewater generated in the p-aminodiphenyl amine production process with nitrate-containing wastewater and homogenizing, regulating the C / N ratio and the pH value of the wastewater, adding N and P nutritive salts, carrying out such treatments as sedimentation and air floatation, and then removing high-concentration organic matters out of the wastewater through an oxygen-poor short-cut denitrification reaction, and generating yielding water containing the nitrite nitrogen, which is advantageous for the subsequent anaerobic ammonia oxidation reaction. The method provided by the invention is low in investment, high in income, simple and convenient to operate and stable in treatment effect; besides, the generated wastewater can be further treated and utilized; and as a result, the purpose of reducing wastewater emission is reached and the economic benefit is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating, desalting and recycling recovered quaternary ammonium base

ActiveCN108997140AReduce viscosityImprove liquidityAmino compound purification/separationOrganic compound preparationOrganic matterP-aminodiphenylamine

The invention discloses a method for separating, desalting and recycling recovered quaternary ammonium base. The method for separating, desalting and recycling the recovered quaternary ammonium base,disclosed by the invention, has the advantages that shortcomings in the prior art of recovering the quaternary ammonium base during using a nitrobenzene method to prepare p-aminodiphenyl amine are eliminated; a procedure of centrifugally separating p-aminodiphenyl amine and macromolecular viscous organic substances in the recovered quaternary ammonium base is increased to reduce the contents of the p-aminodiphenyl amine and macromolecular viscous organic substances in the recovered quaternary ammonium base, reduce the viscosity of the recovered quaternary ammonium base, reduce the desalting and filtering difficulty of the recovered quaternary ammonium base, improve the desalting effect of the recovered quaternary ammonium base and promote normal implementations of follow-up condensation reaction and reduction reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

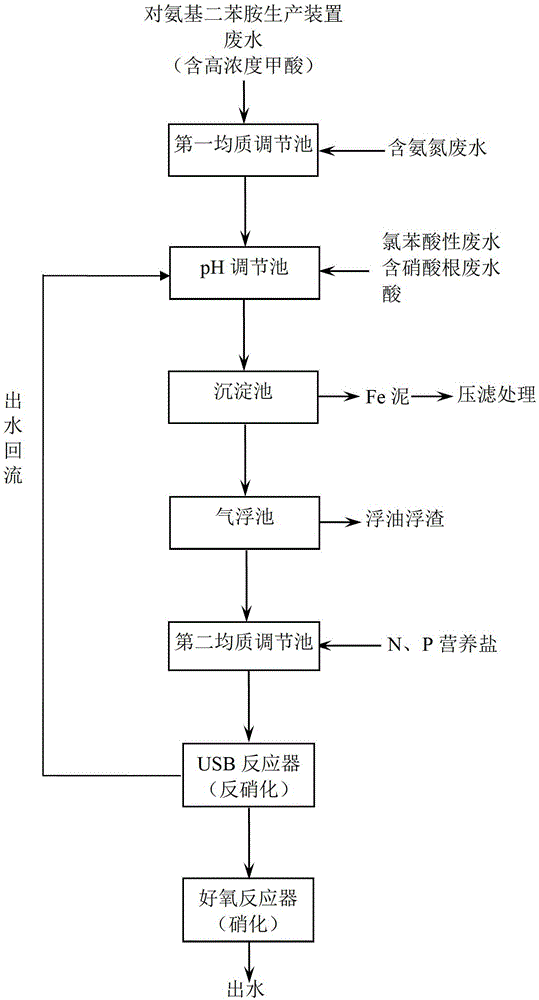

Treatment method of p-aminodiphenylamine production device wastewater

ActiveCN103663843AImprove denitrification effectHigh processing loadMultistage water/sewage treatmentHigh concentrationTreatment effect

The invention provides a treatment method of p-aminodiphenylamine production device wastewater, particularly a high-efficiency treatment method of process wastewater containing high-concentration formic acid. The method comprises the following steps: primary pH regulation of p-aminodiphenylamine production device wastewater, C / N ratio control in a homogenizing tank, secondary pH regulation, air floatation, N and P nutritive salt addition, influent water temperature regulation, biochemical denitrification treatment and the like. After the p-aminodiphenylamine production device wastewater is treated by the treatment procedure provided by the invention and corresponding conditions, the formic acid concentration in the wastewater can be lowered from 160000 mg / L or so to 0.1 mg / L below, and the removal ratio is up to higher than 90%. The method has the advantages of stable treatment effect and low treatment cost, is simple to operate, and can easily implement industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Functionalized graphene oxide, preparation method and application thereof

ActiveCN109535770ASuppress stackingImprove aging resistancePigment treatment with non-polymer organic compoundsIce waterPolyphenol

The invention discloses a preparation method of functionalized graphene oxide. The method includes: under an ice-water bath condition, adding cyanuric chloride into a mixed solution of acetone and water, stirring the substances evenly, adding ammonia water, carrying out reaction at 1-5DEG C for 30-50min, and then conducting filtering, washing and drying to obtain a material A; adding the materialA into 1, 4-dioxane, mixing the substances evenly, adding a 1, 4-dioxane solution of p-aminodiphenyl amine and sodium carbonate, conducting stirring at room temperature for 30-100min, and performing filtering, washing and drying to obtain a material B; adding the material B into 1, 4-dioxane, adding 1H, 1H-perfluorooctylamine, adjusting the pH to 7, carrying out reaction at 80-90DEG C for 3-4h, and conducting standing, filtering and drying to obtain a material C; subjecting graphene oxide to acylating chlorination, then adding the product into dimethylformamide, adding a material C, carrying out reaction at 80-90DEG C for 20-30h, conducting filtering and drying, mixing the obtained material with plant polyphenol and water evenly, carrying out reaction at 35-60DEG C for 30-48h, and performing drying.

Owner:JILIN NORMAL UNIV

Method for treating p-aminodiphenylamine production device wastewater

ActiveCN103663845AImprove denitrification effectGood removal effectMultistage water/sewage treatmentNature of treatment waterHigh concentrationTreatment effect

The invention provides a treatment method of p-aminodiphenylamine production device wastewater, particularly a high-efficiency treatment method of process wastewater containing high-concentration formic acid. The method comprises the following steps: homogenizing the p-aminodiphenylamine production device wastewater, regulating the pH value, controlling the C / N ratio, precipitating, adding N and P nutritive salts, regulating the influent water temperature, carrying out biochemical denitrification treatment and the like. After the p-aminodiphenylamine production device wastewater is treated by the treatment procedure provided by the invention and corresponding conditions, the formic acid concentration in the wastewater can be lowered from 160000 mg / L or so to 0.1 mg / L below, and the removal ratio is up to higher than 90%. The method has the advantages of stable treatment effect and low treatment cost, is simple to operate, and can easily implement industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Platinum catalyst loaded on aminated graphene and preparation method thereof

PendingCN113499764AReduce security risksAvoid sintering deactivationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPlatinum salts

The invention discloses a preparation method of a platinum catalyst loaded on aminated graphene, the preparation method comprises the following steps: pretreating natural crystalline flake graphite, oxidizing the pretreated natural crystalline flake graphite to prepare graphite oxide, performing ultrasonic exfoliation on the graphite oxide to obtain graphene oxide, aminating the graphene oxide to obtain aminated graphene, and adding a platinum salt solution into the aminated graphene to prepare the platinum catalyst loaded on the aminated graphene. The problems of sintering deactivation, large catalyst loss, more impurities in hydrogenation liquid and reduced production capacity caused by local overheating of the catalyst due to the fact that the reduction catalyst cannot timely remove reaction heat in the existing p-aminodiphenylamine production can be solved. The catalyst has the advantages of high activity, high selectivity, good stability, long service life and good application prospect when being used for catalyzing nitrobenzene process hydrogenation to prepare p-aminodiphenylamine.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD +2

Process for the preparation of 4-OXO-4-((4-(phenylamino)phenyl)amino)-2-butenoic acid

InactiveUS20060089511A1Good dispersionEasy to handleOrganic compound preparationCarboxylic acid amides preparation2 Butenoic AcidsOrganic solvent

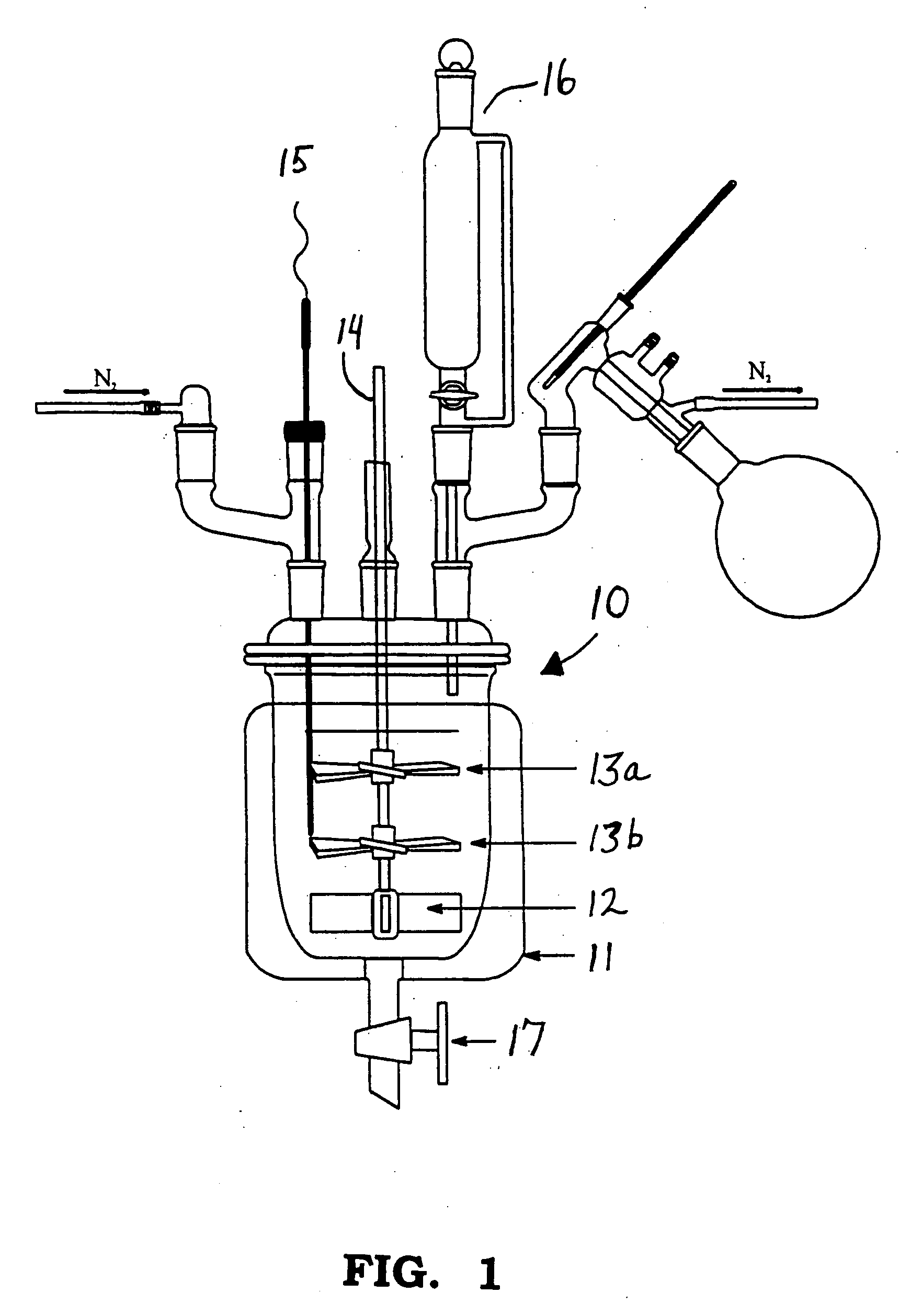

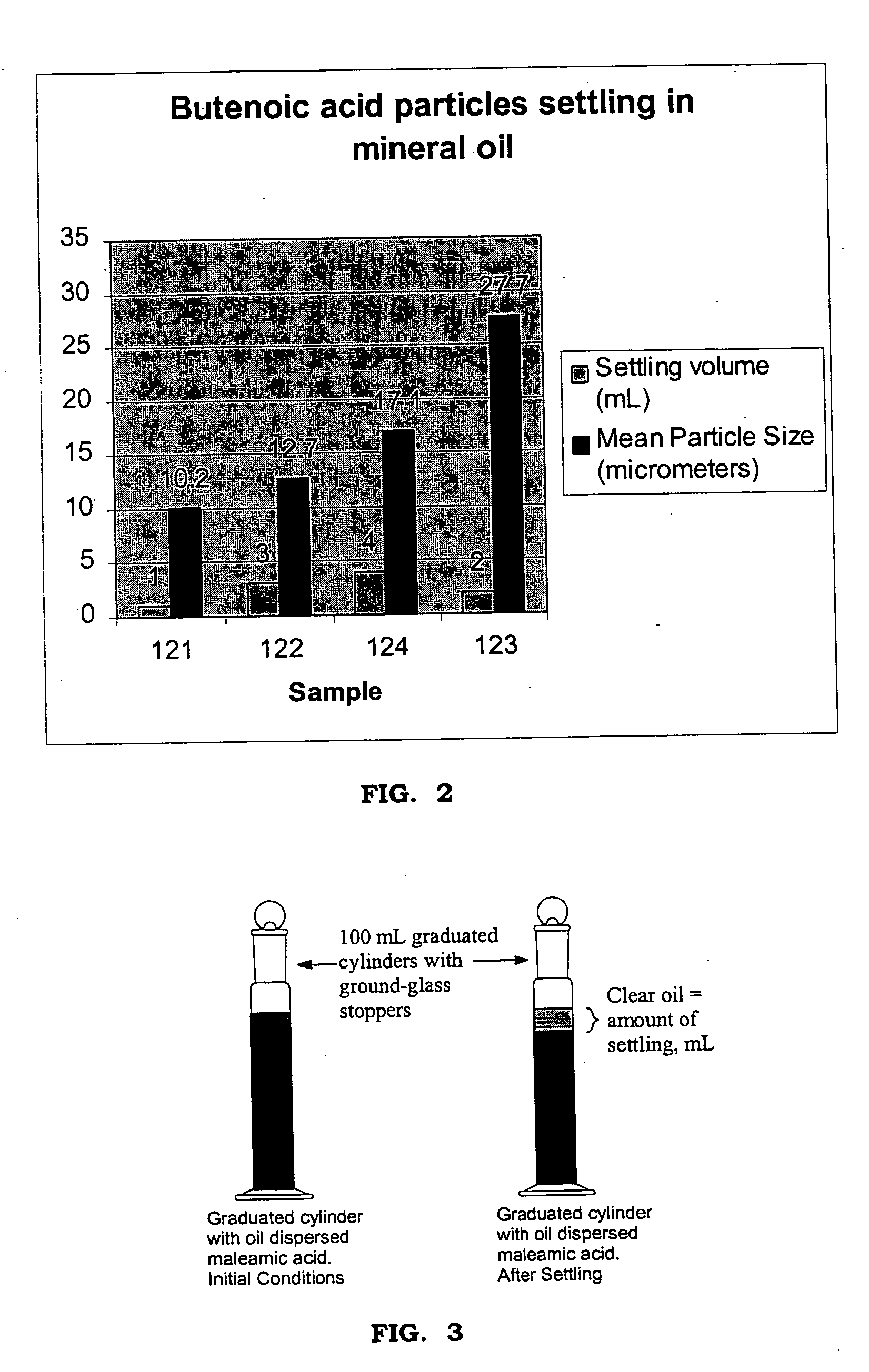

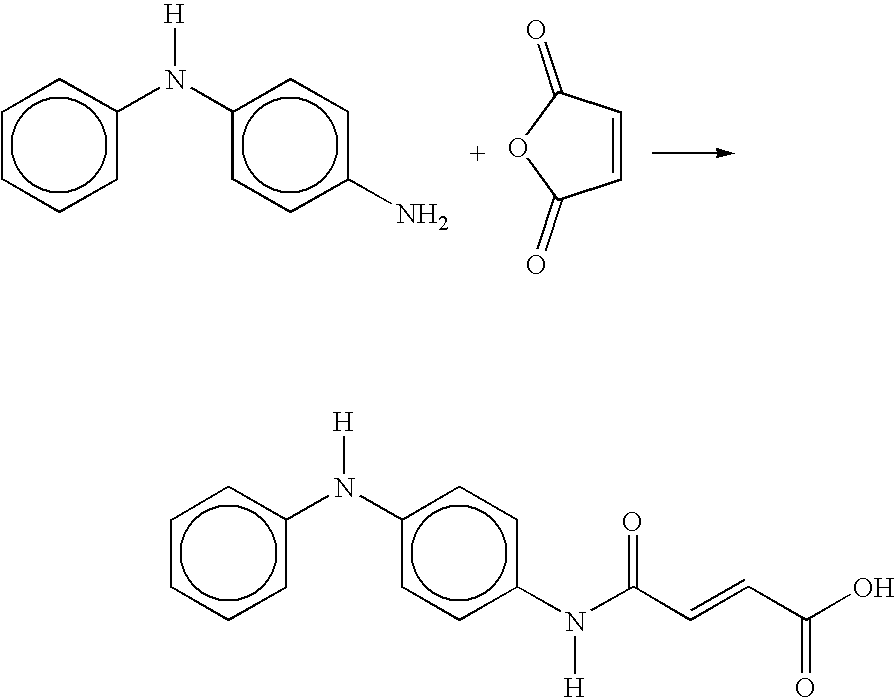

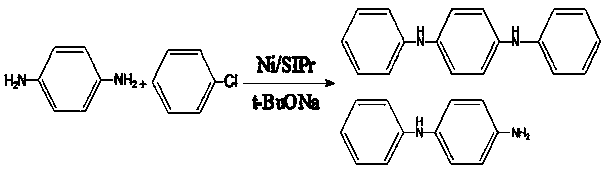

A process for the preparation of 4-oxo-4-((4-(phenylamino)phenyl)amino)-2-butenoic acid includes reacting p-aminodiphenyl amine and maleic anhydride in a reaction first mixture containing a volatile organic solvent under suitable reaction conditions to provide a second mixture containing 4-oxo-4-((4-(phenylamino)phenyl)amino)-2-butenoic acid product; subjecting the second mixture to vacuum distillation to remove the volatile organic solvent while simultaneously adding diluent oil to produce a dispersion of 4-oxo-4-((4-(phenylamino)phenyl)amino)-2-butenoic acid in the diluent oil.

Owner:CROMPTON CORP

Method for continuously preparing p-aminodiphenylamine

InactiveCN108623472AHigh activityReduce generationOrganic compound preparationChemical recyclingOrganic solventP-aminodiphenylamine

The invention provides a method for preparing p-aminodiphenylamine through continuous catalysis. According to the method, 4-nitrodiphenylamine and 4-nitrosodiphenylamine are used as raw materials andsubjected to continuous reduction in the presence of an organic solvent under the catalysis of a supported catalyst so as to obtain p-aminodiphenylamine. The method of the invention solves the problems of environmental pollution, low catalyst activity, difficult catalyst recovery and high labor intensity in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

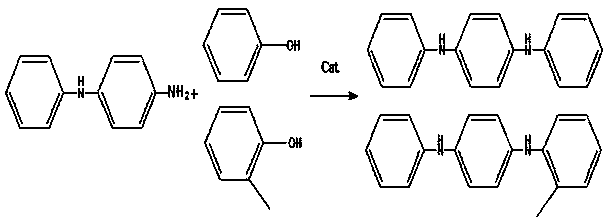

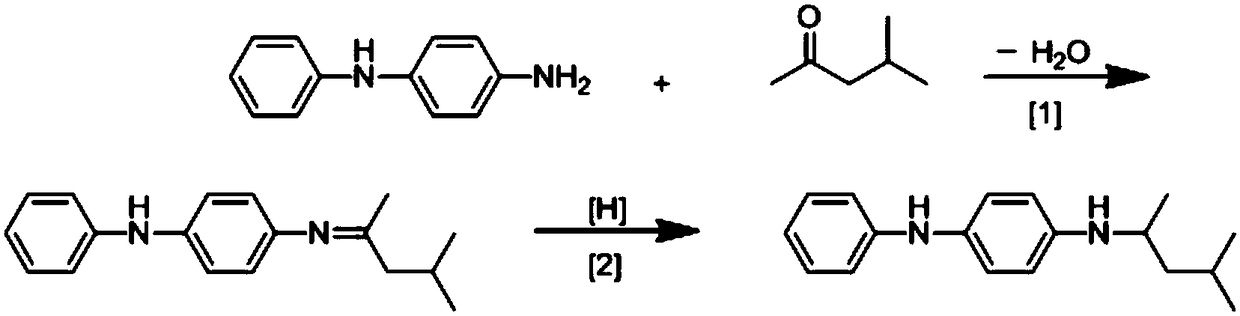

Method for preparing tire antioxidant 3100

The invention discloses a method for preparing a tire antioxidant 3100, belongs to the field of fine chemical synthesis, and concretely relates to a production technology for the tire antioxidant 3100. The production technology comprises the following steps: p-aminodiphenylamine and a catalyst are placed in a reaction vessel, and are heated to 110-140 DEG C, the temperature is kept, vacuumizing iscarried out to -0.06 MPa, a mixture of phenol and o-cresol is added under a stirring condition, the obtained mixture is reacted until no water is evaporated, the temperature is reduced to 90-100 DEGC, and the catalyst is filtered out to obtain the tire antioxidant 3100. The technology has the advantages of easily available raw materials, simple reaction process, mild conditions, low and controlled energy consumption, few generated wastes, and suitableness for large-scale production.

Owner:扬州市业昌助剂有限公司

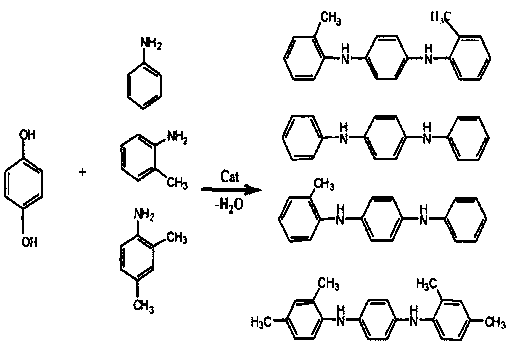

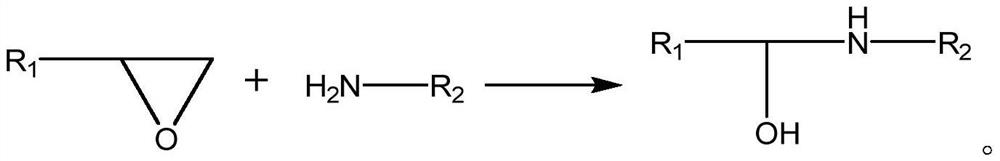

Novel anti-aging agent as well as preparation method and application thereof

PendingCN113956538AReduced ability to migrateExtended service lifeOrganic compound preparationAmino-hyroxy compound preparationEpoxyBiochemical engineering

The invention relates to a novel anti-aging agent and a preparation method and an application thereof, the novel anti-aging agent is a reaction product of p-aminodiphenylamine (PPDA) and an epoxy compound, the epoxy compound is a compound containing an epoxy group and double bonds, and the molar ratio of p-aminodiphenylamine to the epoxy compound is 1: (1-5), preferably 1: (2-4). The anti-aging agent can be used as the anti-aging agent for natural rubber or synthetic rubber. The novel anti-aging agent provided by the invention has lower migration performance and extraction resistance, and can prolong the service life of a rubber product and avoid environmental pollution; the migration rate of the novel anti-aging agent in rubber neutralization is lower than that of a traditional anti-aging agent, so that good stability, low migration rate and good later-stage anti-aging performance of the anti-aging agent can be better guaranteed.

Owner:BEIJING UNIV OF CHEM TECH +1

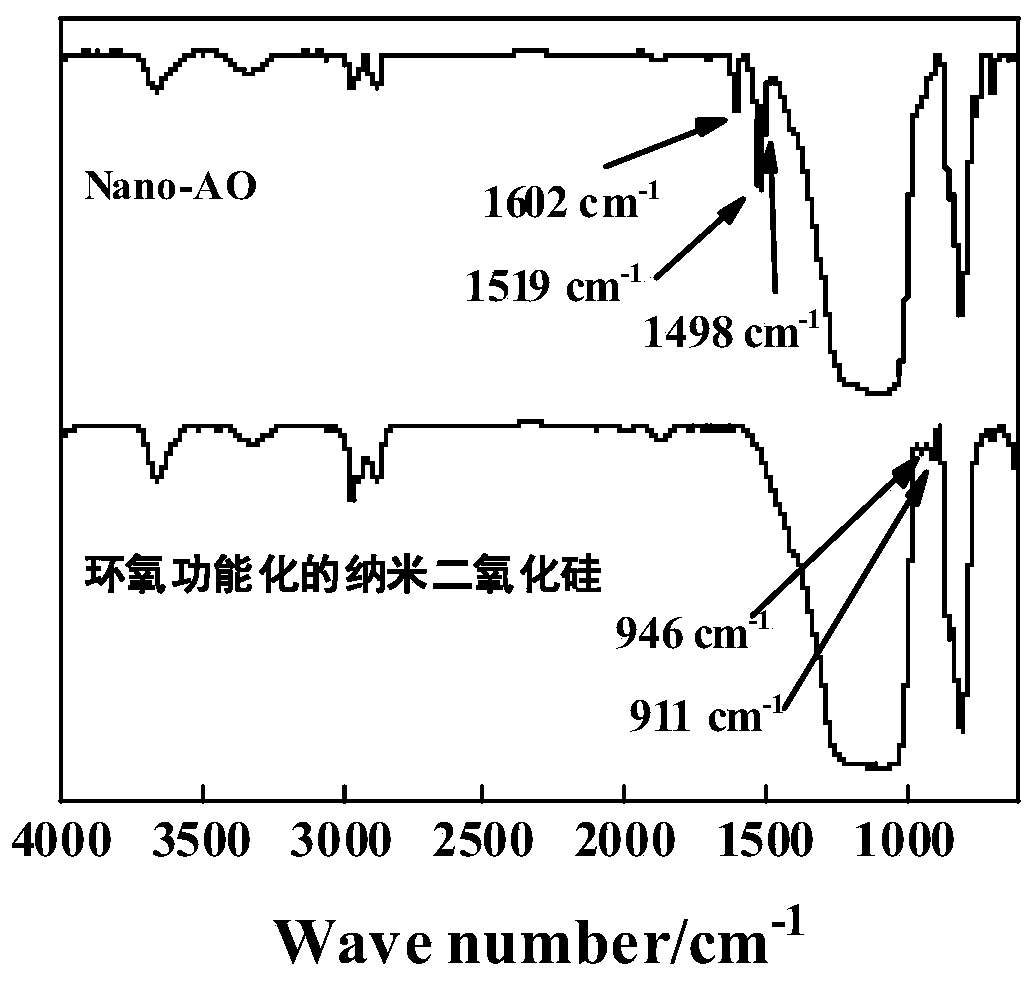

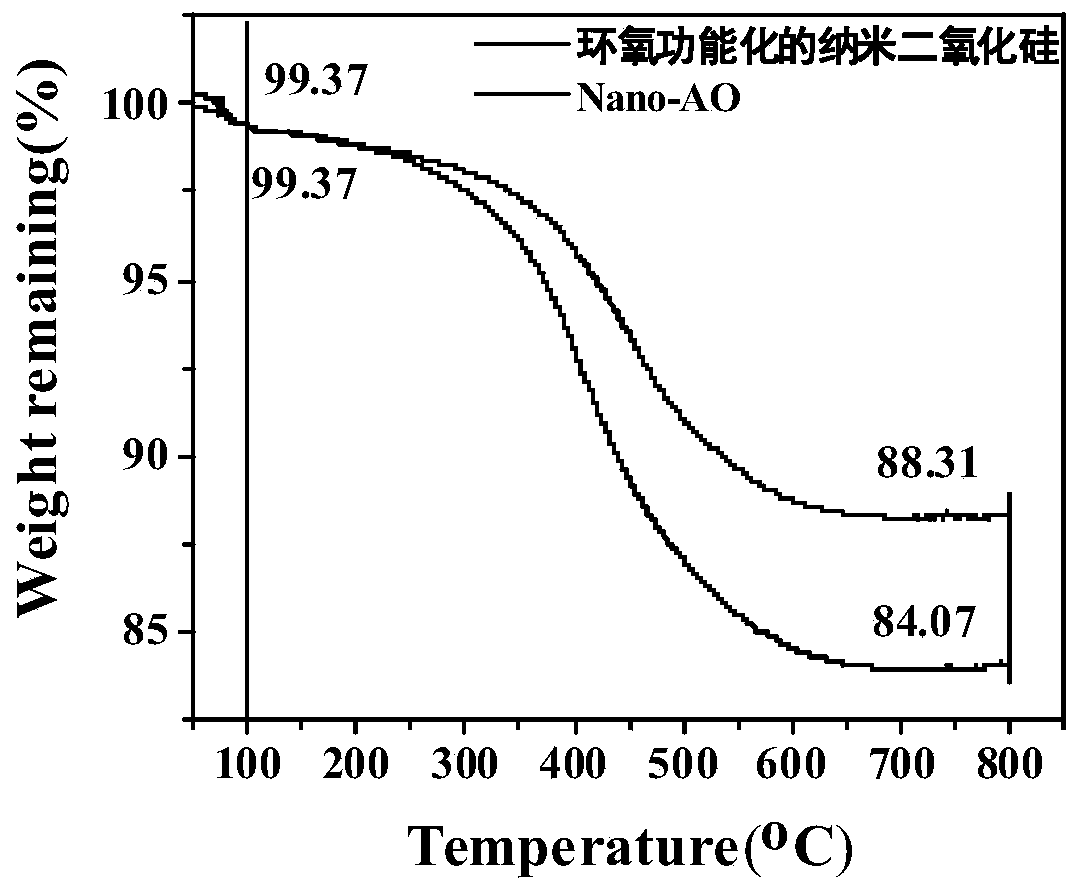

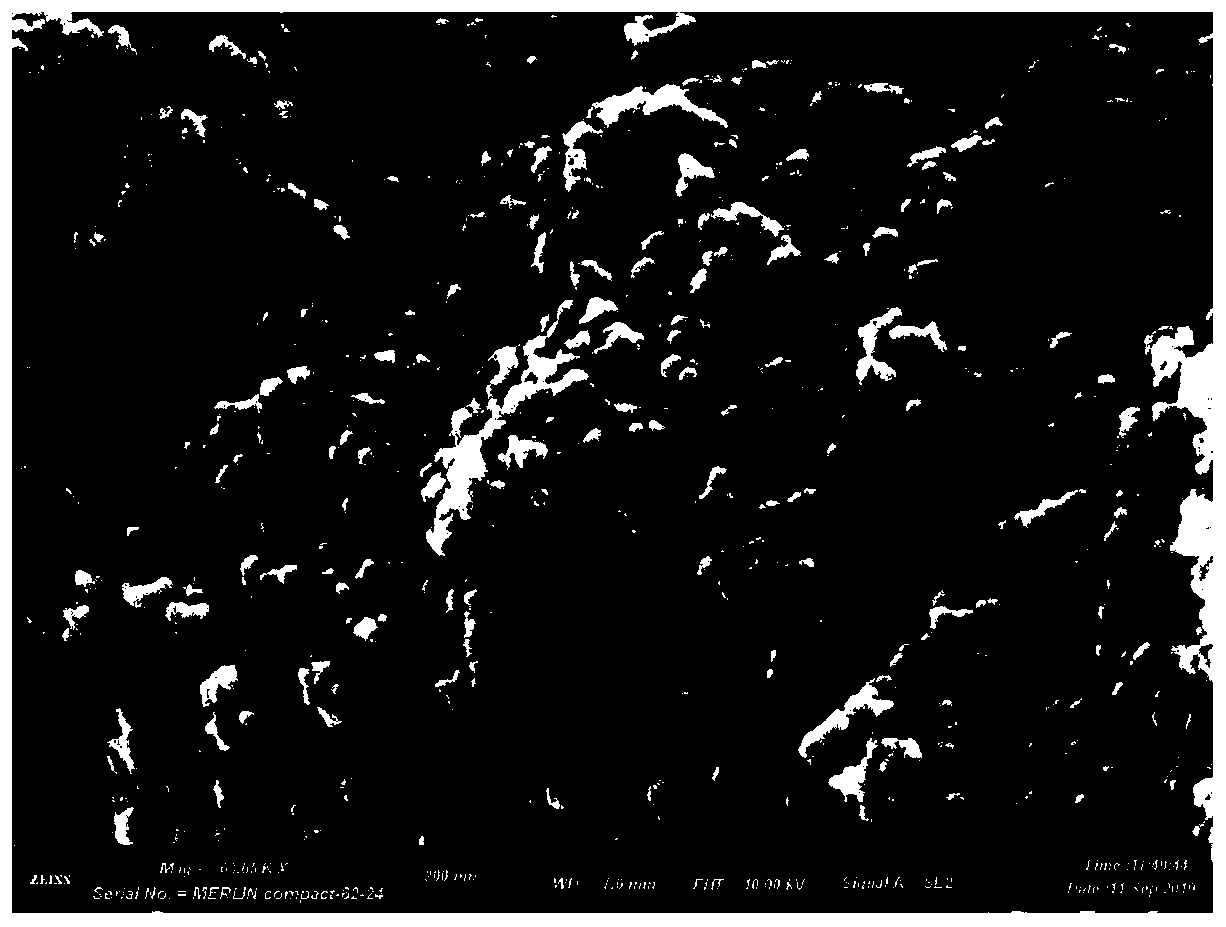

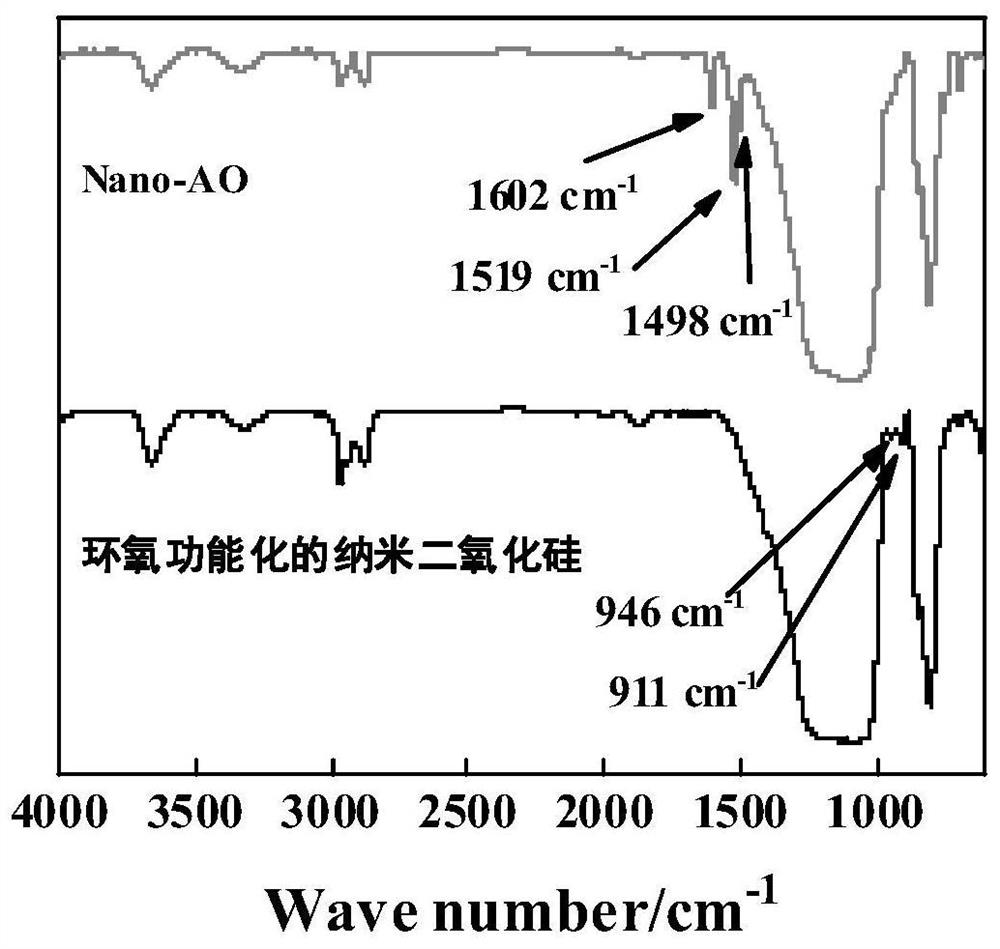

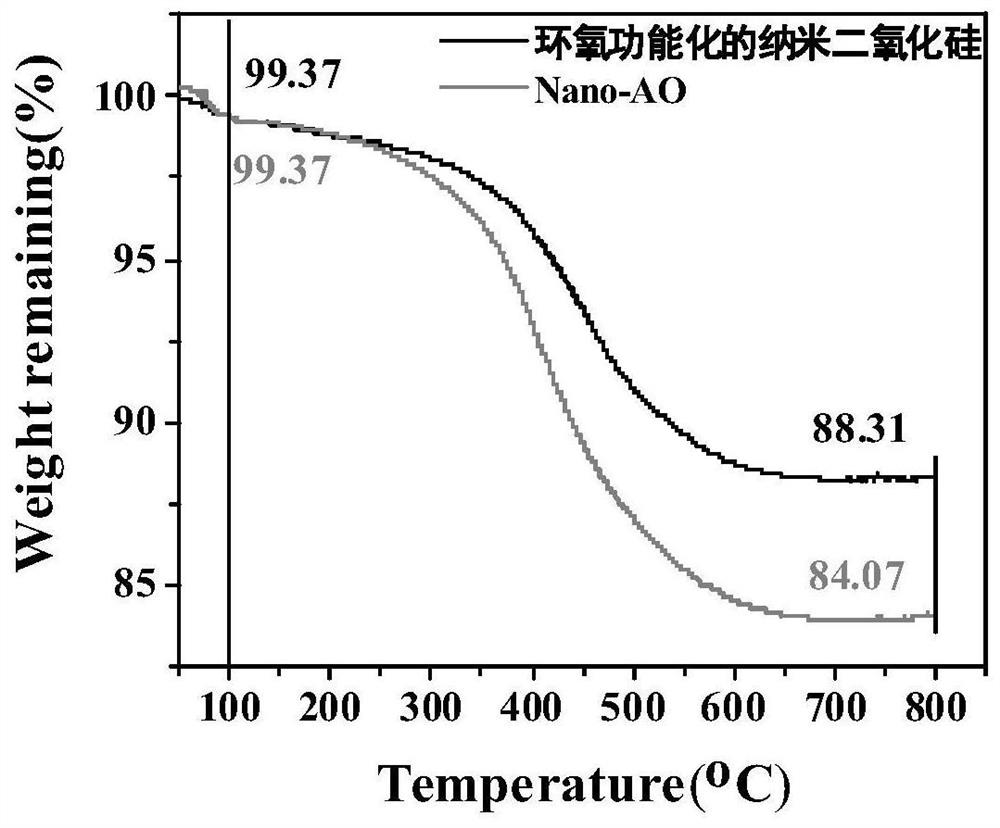

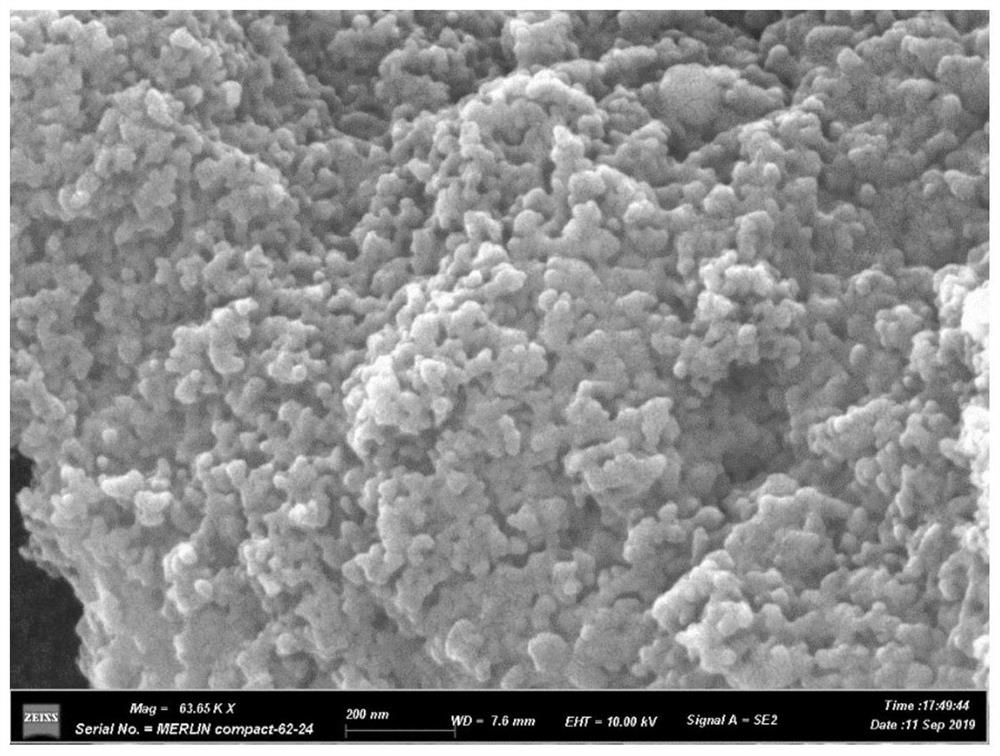

Amine nano additive for lubricating oil and application of additive

ActiveCN110776973AEvenly dispersedAnti-wearSilicon organic compoundsAdditivesGraft reactionOil additive

The invention provides an amine nano additive for lubricating oil and an application of the additive, and relates to the technical field of lubricating materials. The additive is obtained by performing a graft reaction on nano-silicon dioxide containing epoxy groups on the surface and p-aminodiphenylamine, can be applied to hydraulic base oil and significantly improve the anti-oxidation function of the oil, and has good dispersion stability and wear resistance in the lubricating oil.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

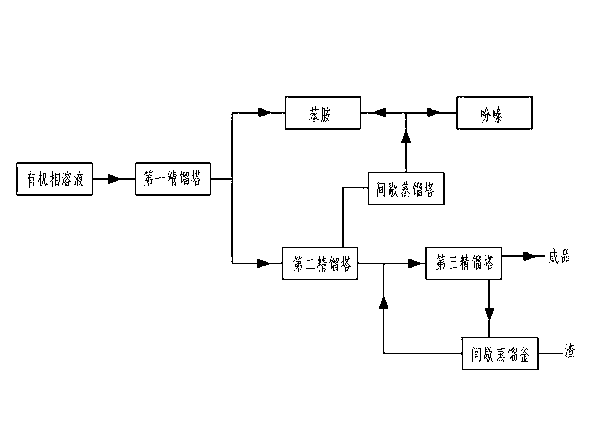

Method for separating p-aminodiphenyl amine reduction solution

InactiveCN106928070AReduce concentrationReduce dosageAmino compound purification/separationP-AminodiphenylSolvent

The present invention is a method for separating p-aminodiphenylamine reducing liquid, which belongs to the field of crude product material separation, and the problem to be solved is to reduce the consumption of crude product material separation; the present invention mainly includes the following steps: solvent distillation, centrifugal separation, inorganic phase concentration, For processes such as organic phase distillation, by adding solvent distillation steps and using centrifugal separation to replace the extraction unit in production, the amount of extraction agent used in the system is greatly reduced, thereby greatly reducing energy consumption by more than 60%.

Owner:运城晋腾化学科技有限公司

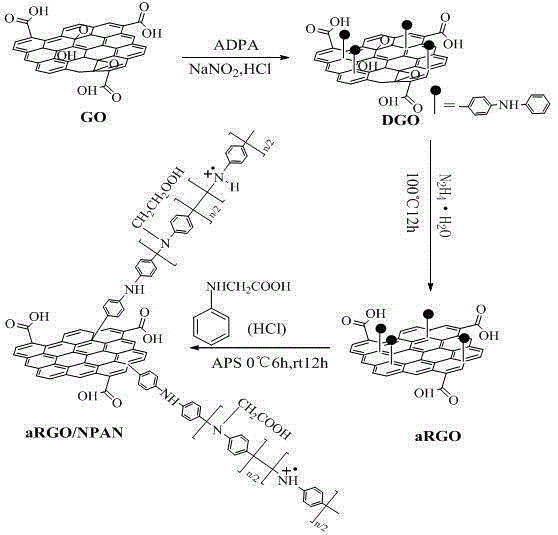

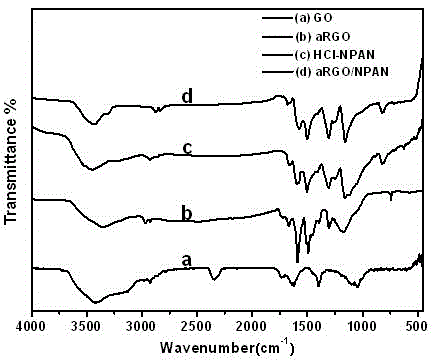

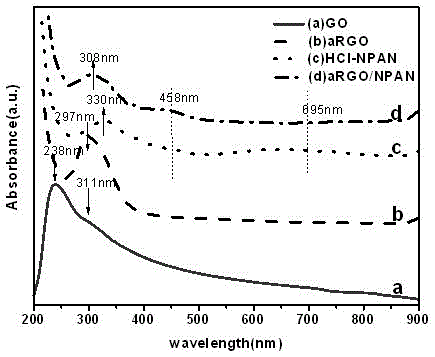

Preparation method of N-substituted carboxylic acid polyaniline covalently grafted graphene composite material

The invention relates to a preparation method of N-substituted carboxylic acid polyaniline covalently grafted graphene composite material. The preparation method of the N-substituted carboxylic acid polyaniline covalently grafted graphene composite material comprises the following steps: taking graphite powder, preparing graphene oxide (GO), and carrying out ultrasonic dispersion to form a uniform solution; then dissolving a certain amount of p-aminodiphenyl amine in a certain volume of mixed solution of concentrated hydrochloric acid and absolute ethyl alcohol, and carrying out ultrasonic dispersion; in ice-water bath, slowly dropwise adding a quantitative NaNO2 solution into the mixed solution, slowly dropwise adding the GO solution after the NaNO2 solution is dropwise added, reacting for a certain period of time, then treating the obtained functional GO, and then reducing by virtue of hydrazine hydrate and ammonia water; and finally dissolving a certain amount RGO and quantitative N-phenylglycin into an HCl solution with constant concentration, carrying out ultrasonic dispersion, adding a certain amount of initiator ammonium persulphate, and reacting for a certain period of time, so that an NPAN covalently grafted RGO composite material is obtained. Electrical conductivity of the prepared composite material can reach 5.0*10<-1>S / cm, and solubility and stability are obviously improved; and the obtained composite material can be applied to the fields of super capacitors, sensor, solar cells and the like.

Owner:EAST CHINA JIAOTONG UNIVERSITY

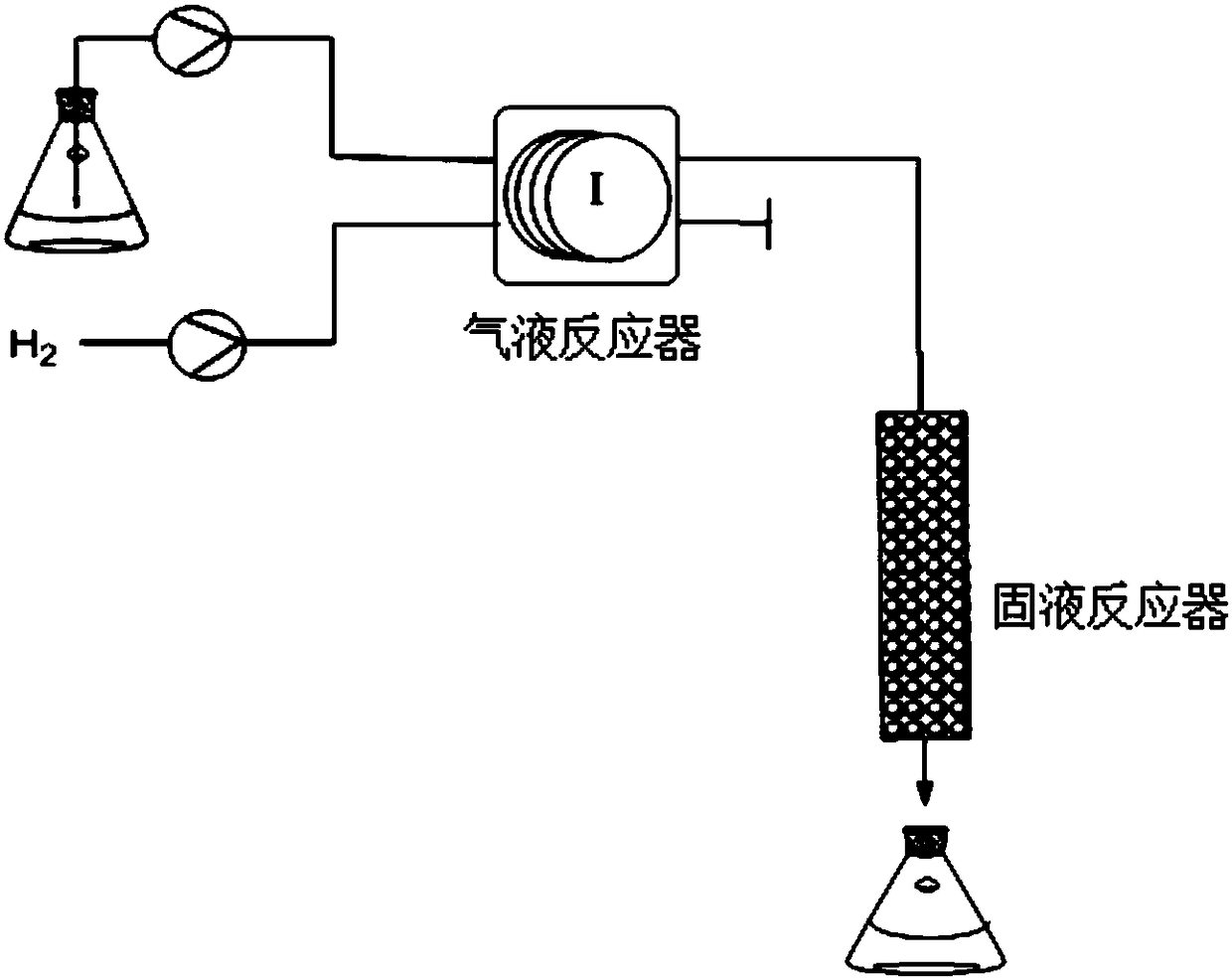

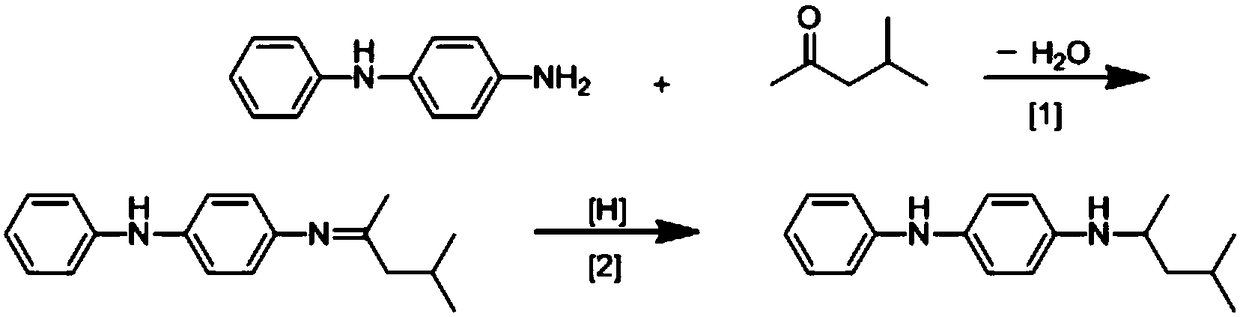

A kind of method that utilizes micro-reaction device to prepare antioxidant 6ppd

ActiveCN106242978BLarge specific surface areaIncrease transfer rateOrganic compound preparationAmino compound preparationReaction temperatureChemistry

The invention discloses a method for preparation of an anti-aging agent 6PPD by using a micro-reactor; a homogeneous solution of p-aminodiphenyl amine and methyl isobutyl ketone and hydrogen gas are subjected to a reaction in a gas-liquid reactor, then are introduced into a solid-liquid reactor and are subjected to a reaction, and the obtained reaction liquid repeats the above operations. Compared with the prior art, the gas-liquid reactor and the solid-liquid reactor are connected in series, the gas-solid-liquid three-phase reaction is performed in a micro-channel, and eventually, the conversion rate of raw materials is improved and the reaction time is shortened. The micro-reactor has the advantages of large specific surface area and strong heat transfer and mass transfer abilities, and enables the reactions to be carried out efficiently; and the reaction temperature, time and material ratio and other conditions can be precisely controlled through the micro-channel reactor, by-products are reduced, and the security is improved.

Owner:NANJING TECH UNIV

A kind of amine nano lubricating oil additive and application

ActiveCN110776973BEvenly dispersedAnti-wearSilicon organic compoundsAdditivesOil additiveP-aminodiphenylamine

The invention provides an amine nano lubricating oil additive and its application, and relates to the technical field of lubricating materials. The additive is obtained by grafting reaction of nano silicon dioxide containing epoxy groups on the surface and p-aminodiphenylamine, and can be applied to hydraulic pressure In the oil base, it significantly improves the anti-oxidation function of the oil, and has good dispersion stability and anti-wear performance in lubricating oil.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Separation method of hydrogenated mixed liquor in production process of p-aminodiphenylamine

ActiveCN108033884AIncrease specific gravity differenceHigh speedAmino compound purification/separationChemical recyclingTetramethylammonium hydroxideDistillation

The invention relates to the technical field of production of rubber antioxidant midbody, and particularly discloses a separation method of a hydrogenated mixture in the production process of p-aminodiphenylamine. The separation method is characterized in that hydrogenated mixed liquid is sent to a desolventizer tower to remove hydrogenation reaction solvent alcohol, and the rest mixed liquid is recovered from the tower bottom; the tower bottom mixed liquid is sent to an extraction separating tower, meanwhile an extraction solvent is melted in the tower, aniline and p-aminodiphenylamine in themixed liquid are extracted out to serve as an oil phase to be extracted from the tower top of the extraction tower, and a tetramethyl ammonium hydroxide water solution is extracted from the tower bottom; and the oil phase is sent to a distillation separation procedure, an extraction agent and aniline are steamed from the tower top respectively, and p-aminodiphenylamine is extracted out from the tower bottom. Compared with a traditional separation method, the separation method effectively improves the layering speed and the separation effect of the oil phase and a water phase, water consumption amount is small, the postprocessing difficult for recycling a condensation catalyst-tetramethyl ammonium hydroxide is reduced, consumption of the condensation catalyst is decreased, meanwhile the extraction agent is easy to recycle for cycle use, and the method is convenient and rapid, and economical and effective.

Owner:QINGDAO UNIV OF SCI & TECH

Method for accumulating nitrite nitrogen by performing short-cut denitrification on p-aminodiphenyl amine production wastewater

ActiveCN103663846BImprove removal efficiencyLow costMultistage water/sewage treatmentHigh concentrationTherapeutic effect

The invention provides a method for accumulating nitrite nitrogen by performing short-cut denitrification on p-aminodiphenyl amine production wastewater. The method comprises the following steps of: mixing formic acid-containing wastewater generated in the p-aminodiphenyl amine production process with nitrate-containing wastewater and homogenizing, regulating the C / N ratio and the pH value of the wastewater, adding N and P nutritive salts, carrying out such treatments as sedimentation and air floatation, and then removing high-concentration organic matters out of the wastewater through an oxygen-poor short-cut denitrification reaction, and generating yielding water containing the nitrite nitrogen, which is advantageous for the subsequent anaerobic ammonia oxidation reaction. The method provided by the invention is low in investment, high in income, simple and convenient to operate and stable in treatment effect; besides, the generated wastewater can be further treated and utilized; and as a result, the purpose of reducing wastewater emission is reached and the economic benefit is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reparing p-aminodiphenylamine through solid base method

InactiveCN110627660AEasy to produceLow energy and material consumptionOrganic compound preparationAmino compound preparationTetramethylammonium hydroxideNitroso

According to the invention, condensation is carried out at a temperature of 60-100 DEG C by using a platinum-loaded macroporous polystyrene strong base resin as a condensation catalyst and using aniline and nitrobenzene as raw materials to prepare 4-(nitroso)nitrodiphenylamine, and hydrogenation reduction is carried out on the obtained condensation liquid so as to prepare p-aminodiphenylamine; andwith the application of the method in preparation of p-aminodiphenylamine, the complex recovery processes such as liquid alkali concentration, desalination and the like are not needed so as to simplify the production process and reduce the energy consumption and the material consumption, tetramethylammonium hydroxide easily decomposed to generate trimethylamine is not adopted so as to achieve environmental protection, the conversion rate of nitrobenzene is greater than or equal to 95%, and the selectivity of 4-(nitroso)nitrodiphenylamine is greater than or equal to 93%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of diazo photosensitizer

PendingCN112279986AShorten the synthesis processReduce drying processPhotomechanical apparatusPolyoxymethyleneO-Phosphoric Acid

The invention discloses a preparation method of a diazonium photosensitizer, which comprises the following steps: 1) mixing concentrated sulfuric acid and phosphoric acid according to a proper ratio to obtain a mixed acid, cooling, and slowly adding a proper amount of p-aminodiphenylamine diazonium sulfate (VRT) which is a wet product; wherein the temperature is controlled to be 20-40 DEG C when the p-aminodiphenylamine diazonium sulfate is added; 2) slowly adding a proper amount of paraformaldehyde after the dissolution in the step 1) is finished, and reacting at the temperature of below 40 DEG C until the reaction is complete; 3) dissolving a reaction solution completely reacted in the step 2) in water, adding a proper amount of a chlorine salt, and separating out a yellow precipitate; and 4) filtering, and drying the yellow precipitate to obtain the product. According to the preparation method disclosed by the invention, reaction with paraformaldehyde is carried out in the mixed acid, the reaction temperature can be effectively increased, the direct damage effect of the concentrated sulfuric acid on the raw materials is reduced, the reaction can be carried out at a relatively high temperature which is easier to control, the weight of the synthesized photosensitizer required for photoresist mixing is reduced to 90%, and the cost is saved.

Owner:浙江荣生科技有限公司

A method for treating waste water from the production of ammonia nitrogen-containing p-aminodiphenylamine

ActiveCN104250053BImprove removal efficiencyHigh volume loadMultistage water/sewage treatmentNature of treatment waterHigh concentrationNitration

The invention relates to a method for treating ammonia-nitrogen containing p-aminodiphenyl amine production wastewater. The method comprises the steps: firstly, mixing and homogenizing the p-aminodiphenyl amine production wastewater and phenylamine production wastewater; then allowing the wastewater to enter a pH regulation tank, successively adding Fe-containing chlorobenzene acidic wastewater, a nitrate-containing solution or wastewater, alkaline denitrification backflow water and dilution water, and finally, adding an acid to adjust the pH value; allowing Fe in the mixed wastewater to form a flocculant Fe(OH)3, and carrying out precipitation treatment; then further removing impurities in an air flotation tank; allowing effluent in the air flotation tank to enter a homogeneous adjusting tank, and adding N and P nutritive salts; finally, removing high-concentration organic compounds in the wastewater through a denitrification reaction; and carrying out a nitration reaction by using the alkalinity generated in the denitrification process to remove ammonia nitrogen in the wastewater, and reaching standards to discharge. The treatment method has the advantages of less investment, high income, simple operation, and stable treatment effect; and the produced wastewater can be further treated and utilized, not only is the purpose of reducing wastewater emissions achieved, but also economic benefits are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of separation method of hydrogenation mixed liquor in the production of p-aminodiphenylamine

ActiveCN108033884BIncrease specific gravity differenceHigh speedAmino compound purification/separationChemical recyclingTetramethylammonium hydroxidePtru catalyst

The invention relates to the technical field of production of rubber antioxidant midbody, and particularly discloses a separation method of a hydrogenated mixture in the production process of p-aminodiphenylamine. The separation method is characterized in that hydrogenated mixed liquid is sent to a desolventizer tower to remove hydrogenation reaction solvent alcohol, and the rest mixed liquid is recovered from the tower bottom; the tower bottom mixed liquid is sent to an extraction separating tower, meanwhile an extraction solvent is melted in the tower, aniline and p-aminodiphenylamine in themixed liquid are extracted out to serve as an oil phase to be extracted from the tower top of the extraction tower, and a tetramethyl ammonium hydroxide water solution is extracted from the tower bottom; and the oil phase is sent to a distillation separation procedure, an extraction agent and aniline are steamed from the tower top respectively, and p-aminodiphenylamine is extracted out from the tower bottom. Compared with a traditional separation method, the separation method effectively improves the layering speed and the separation effect of the oil phase and a water phase, water consumption amount is small, the postprocessing difficult for recycling a condensation catalyst-tetramethyl ammonium hydroxide is reduced, consumption of the condensation catalyst is decreased, meanwhile the extraction agent is easy to recycle for cycle use, and the method is convenient and rapid, and economical and effective.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com