A kind of amine nano lubricating oil additive and application

A technology of lubricating oil additives and additives, applied in additives, lubricating compositions, petroleum industry, etc., can solve the problems of poor dispersion of nano-additives and reduce the anti-oxidation ability of oil products, and achieve anti-wear and anti-oxidation effects and excellent anti-oxidation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Mix 4g of epoxy-functionalized nano-silica (particle size 7-25nm) and 60g of p-aminodiphenylamine, add 15mL of toluene as a solvent, heat up to 140°C, reflux for 6h, and filter at room temperature after the reaction The crude product was collected, rinsed with 20 g of absolute ethanol each time, washed three times, and dried in a blast drying oven at 90°C for 2 hours to obtain the product Nano-AO of the present invention.

[0023]

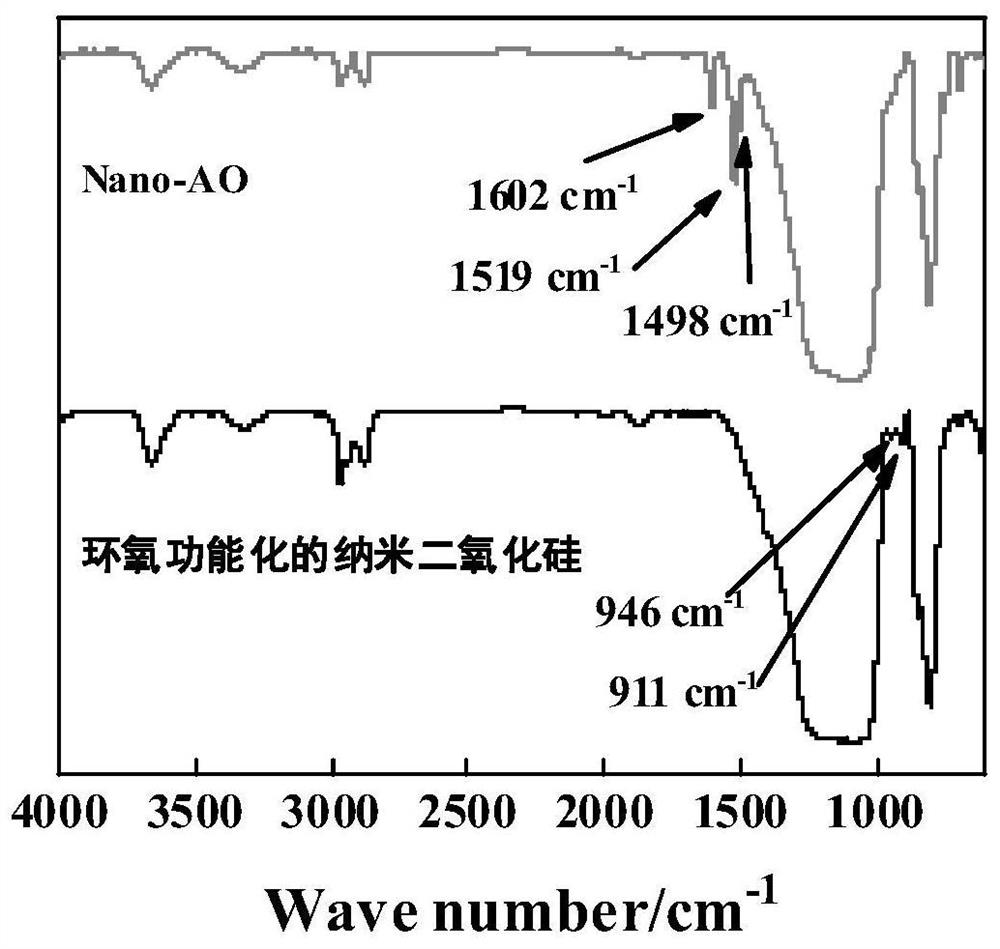

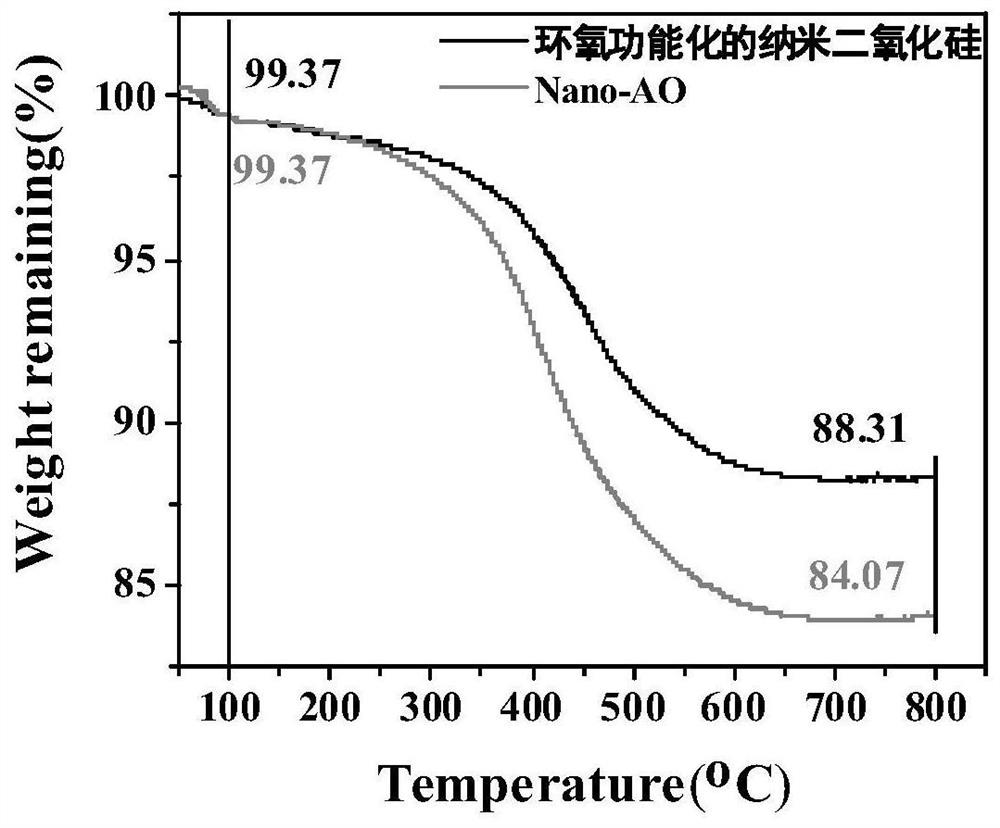

[0024] See attached Picture 1-1 And attached Figure 1-2 , referring to Table 1, by comparing the infrared spectrogram and thermogravimetric test results of the product of Example 1 and the epoxy-functionalized nano-silica, it can be judged that the product obtained in Example 1 is the target grafted product.

[0025] Table 1 embodiment 1 product and the infrared spectrum test result of epoxy functionalized nano silicon dioxide

[0026]

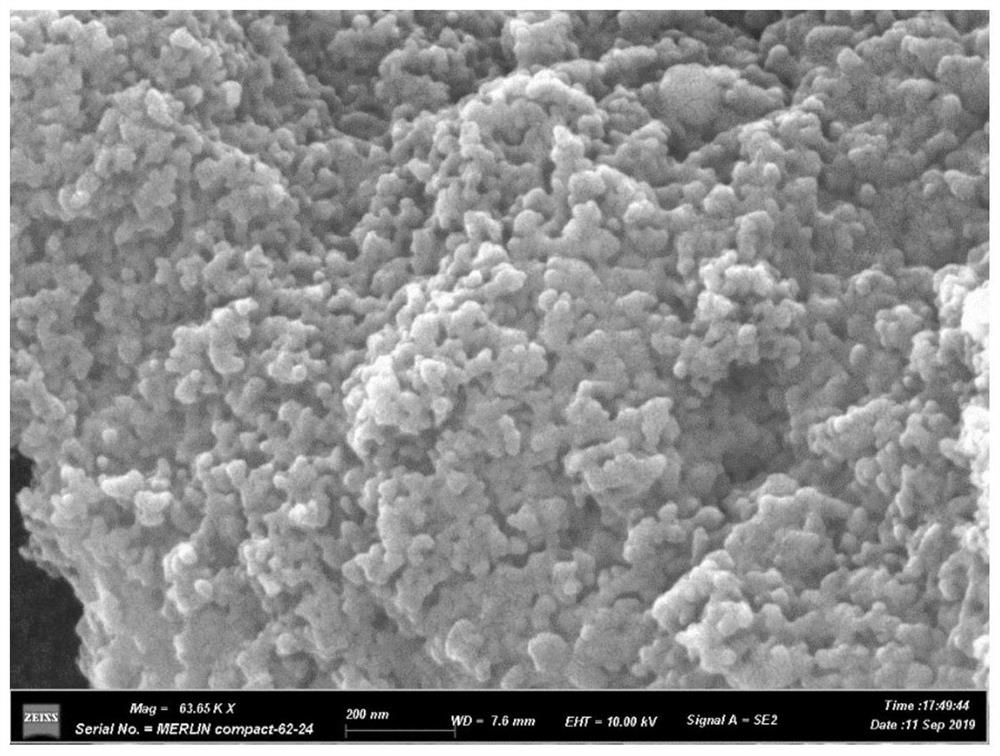

[0027] See attached figure 2 , the product obtained in Example 1 was observed with a scanning ...

Embodiment 2

[0029] The Nano-AO obtained in Example 1 was added to 46# hydraulic oil base oil at 0.1 wt.%, mechanically stirred for 10 minutes and then ultrasonicated for 10 minutes.

[0030] The effects of the additives obtained in Example 1 on the anti-oxidation and anti-wear properties of the base oil were evaluated. The evaluation results of anti-wear ability are shown in Table 2.

[0031] Table 2 Effect of Nano-AO on wear resistance of 46# hydraulic oil base oil

[0032]

[0033] The smaller the diameter of the wear scar, the better the anti-wear ability. It can be seen from Table 2 that the anti-wear ability of the base oil with 0.1wt.% additive is improved.

[0034] The oxidation resistance of the oil added with the additive obtained in Example 1 was investigated by using the temperature-programmed method of pressure differential scanning calorimetry (PDSC). The higher the initial oxidation temperature, the better the oxidation resistance. The temperature-programmed method uses...

Embodiment 3

[0036] The Nano-AO obtained in Example 1 was added to 150SN base oil (Type I) at 0.1 wt.%, mechanically stirred for 10 minutes and then ultrasonicated for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com