A kind of method that utilizes micro-reaction device to prepare antioxidant 6ppd

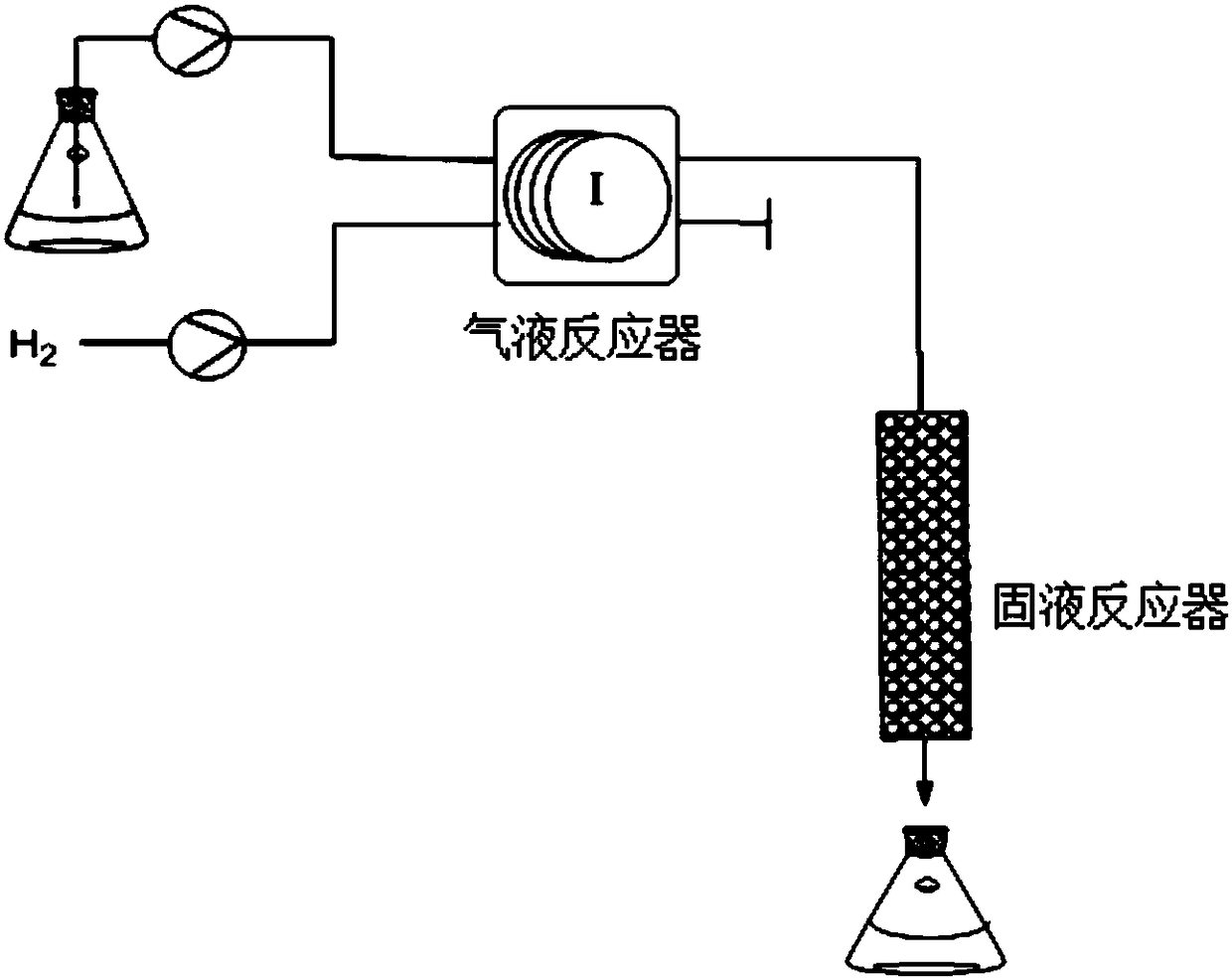

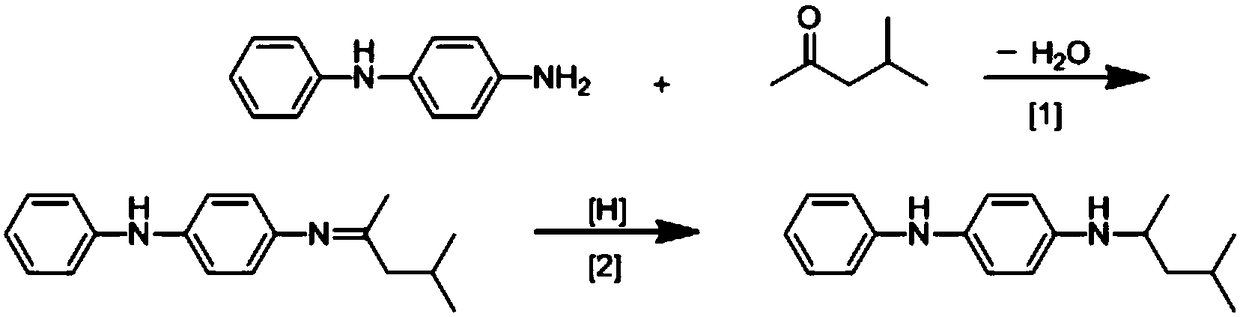

A technology of micro-reaction device and anti-aging agent, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of low yield and long reaction time, and achieve large specific surface area, good product quality, The effect of high operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the microchannel reaction device, the diameter of the connecting pipe is 1 mm, the length of the liquid inlet pipe is 15 cm, the length of the connecting pipe between the microreactor and the outlet is 20 cm, and the specification of the back pressure valve is 8 bar.

[0031] Take 5g of p-aminodiphenylamine, add 200mL of methanol, and weigh 6.8g of methyl isobutyl ketone into the solution, stir at room temperature for 5min, mix evenly, transfer to the Erlenmeyer flask and pass into the microreactor. Pre-introduce hydrogen, exhaust the air in the gas-liquid reactor, block the gas outlet, adjust the hydrogen pressure reducing valve, the pressure is 10bar, and the gas flow rate is controlled by the gas flow meter to 0.05L / min. The liquid flow rate was controlled to be 0.3 mL / min, and the temperature was controlled to be 100°C. The liquid outlet is connected to the solid-liquid reactor filled with catalyst, and the temperature of the reactor is controlled at 100°C. The e...

Embodiment 2

[0033] In the microchannel reaction device, the inner diameter of the connecting pipe is 1 mm, the length of the liquid inlet pipe is 15 cm, the length of the connecting pipe between the microreactor and the outlet is 20 cm, and the specification of the back pressure valve is 8 bar.

[0034] Take 5g of p-aminodiphenylamine, add 200mL of methanol, and weigh 6.8g of methyl isobutyl ketone into the solution, stir at room temperature for 5min, mix evenly, transfer to the Erlenmeyer flask and pass into the microreactor. Pre-introduce hydrogen, exhaust the air in the gas-liquid reactor, block the gas outlet, adjust the hydrogen pressure reducing valve, the pressure is 10bar, and the gas flow rate is controlled by the gas flow meter to 0.1L / min. The liquid flow rate was controlled to be 1.0 mL / min, and the temperature was controlled to be 80°C. The liquid outlet is connected to the solid-liquid reactor filled with catalyst, and the temperature of the reactor is controlled at 80°C. Th...

Embodiment 3

[0036] In the microchannel reaction device, the diameter of the connecting pipe is 1 mm, the length of the liquid inlet pipe is 15 cm, the length of the connecting pipe between the microreactor and the outlet is 20 cm, and the specification of the back pressure valve is 8 bar.

[0037] Take 5g of p-aminodiphenylamine, add 200mL of methanol, and weigh 6.8g of methyl isobutyl ketone into the solution, stir at room temperature for 5min, mix evenly, transfer to the Erlenmeyer flask and pass into the microreactor. Pre-introduce hydrogen, exhaust the air in the gas-liquid reactor, block the gas outlet, adjust the hydrogen pressure reducing valve, the pressure is 10bar, and the gas flow rate is controlled by the gas flow meter to 0.05L / min. The liquid flow rate was controlled to be 1 mL / min, and the temperature was controlled to be 100°C. The liquid outlet is connected to the solid-liquid reactor filled with catalyst, and the temperature of the reactor is controlled at 100°C. The eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com