Preparation method of N-substituted carboxylic acid polyaniline covalently grafted graphene composite material

A technology of covalent grafting and composite materials is applied in the field of preparation of N-substituted carboxylic acid polyaniline covalently grafted graphene composite materials, and can solve the problems of poor compatibility of composite materials, low product purity, and difficulty in popularization and use. , to achieve the effect of inhibiting agglomeration, universal applicability, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

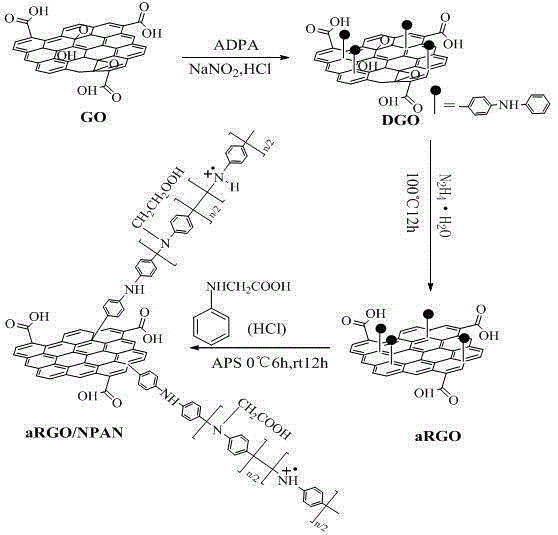

[0038] This example will illustrate that the method of the present invention uses graphene oxide and p-aminodiphenylamine at a mass ratio of 1:5 to functionalize and partially reduce GO, and then use ammonium persulfate as an oxidizing agent, and the ratio of RGO and N-phenylglycine The mass ratio is 1:2, which is realized according to the chemical oxidation polymerization reaction path.

[0039] GO (100 mg) prepared by the Hummer method was dispersed in 100 ml of DI and sonicated for 30 min to present a uniform dispersion. In a 50ml beaker, dissolve 0.5g of p-aminodiphenylamine (ADPA) in a mixture of 20ml of concentrated hydrochloric acid and 20ml of absolute ethanol (about 6M HCl), and sonicate until dissolved (about 15min). Under ice-water bath, 0.228g of NaNO2 was dissolved in 75ml of ice DI to form a solution. Slowly drop into the above mixture, and continue to stir at this temperature for half an hour after the drop; then slowly drop the above GO dispersion into the ice...

Embodiment 2

[0043] This example will illustrate that the method of the present invention uses graphene oxide and p-aminodiphenylamine at a mass ratio of 1:5 to functionalize and partially reduce GO, and then use ammonium persulfate as an oxidizing agent, and the ratio of RGO and N-phenylglycine The mass ratio is 1:1, which is realized according to the chemical oxidation polymerization reaction path.

[0044] GO (100 mg) prepared by the Hummer method was dispersed in 100 ml of DI and sonicated for 30 min to present a uniform dispersion. In a 50ml beaker, dissolve 0.5g of p-aminodiphenylamine (ADPA) in a mixture of 20ml of concentrated hydrochloric acid and 20ml of absolute ethanol (about 6M HCl), and sonicate until dissolved (about 15min). Under ice-water bath, 0.228g of NaNO2 was dissolved in 75ml of ice DI to form a solution. Slowly drop into the above mixture, and continue to stir at this temperature for half an hour after the drop; then slowly drop the above GO dispersion into the ice...

Embodiment 3

[0048] Repeat Example 1, but change the mass ratio of graphene oxide and p-aminodiphenylamine to 1:2 to obtain a composite material conductivity of 1.3×10 -1 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com