Silane coupling agent and preparation method thereof

The technology of a silane coupling agent and coupling agent, which is applied in the field of chemical engineering, can solve the problems of volatilization and migration of antioxidants, incompatibility between inorganic fillers and organic materials, etc., and achieves simplified processing, outstanding anti-aging performance, and simple preparation method. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

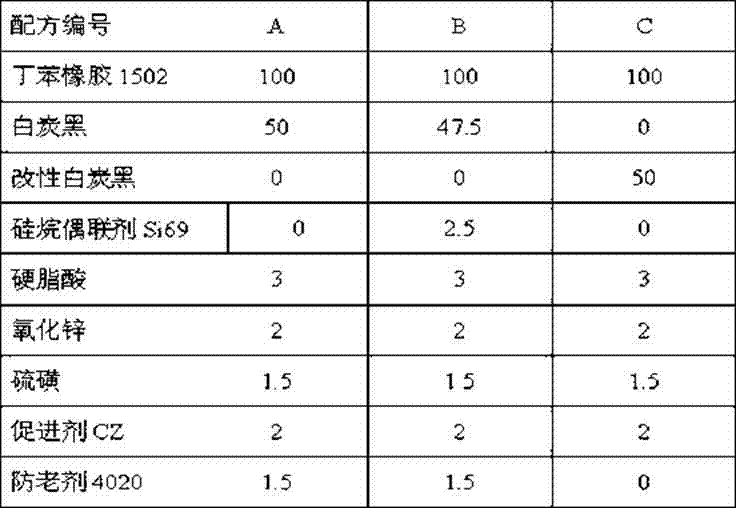

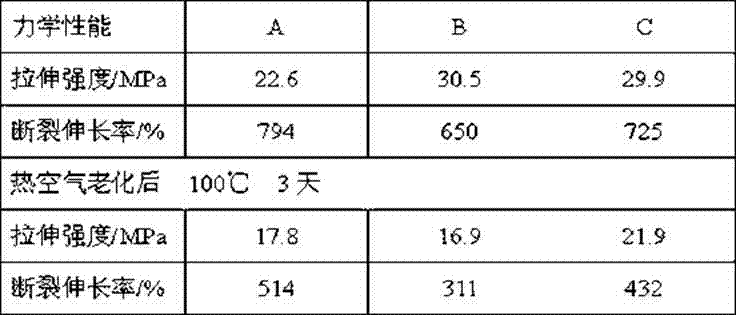

Examples

Embodiment 1

[0019] Mix the coupling agent γ-glycidyl etheroxypropyl trimethoxysilane and p-aminodiphenylamine (PPDA) in the three-necked flask at a molar ratio of 1:1, and start to pass into the three-necked flask from 5 minutes before starting to heat up Nitrogen until the end of the reaction, raise the temperature to 135°C, and continue the reaction for 3.5 hours under magnetic stirring to obtain the product. Infrared detection shows 910cm -1 The epoxy group absorption peak disappeared, and the HPLC-MS results showed that the product only contained anti-aging silane coupling agent and a small amount of PPDA.

Embodiment 2

[0021] Mix the coupling agent γ-glycidyl etheroxypropyltrimethoxysilane and p-aminodiphenylamine (PPDA) in the three-necked flask at a molar ratio of 1:1.1, and start to pass into the three-necked flask from 10 minutes before starting to heat up Nitrogen until the end of the reaction, the temperature was raised to 140 ° C, and the reaction was continued for 3 hours under magnetic stirring to obtain the product. Infrared detection shows 910cm -1 The epoxy group absorption peak disappeared, and the HPLC-MS results showed that the product only contained anti-aging silane coupling agent and a small amount of PPDA.

Embodiment 3

[0023] Mix the coupling agent γ-glycidyl etheroxypropyl trimethoxysilane and p-aminodiphenylamine (PPDA) in the three-necked flask at a molar ratio of 1:1.2, and start to pass into the three-necked flask from 15 minutes before starting to heat up. Nitrogen until the end of the reaction, the temperature was raised to 145 ° C, and the reaction was continued for 2.5 hours under magnetic stirring to obtain the product. Infrared detection shows 910cm -1 The epoxy group absorption peak disappeared, and the HPLC-MS results showed that the product only contained anti-aging silane coupling agent and a small amount of PPDA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com