Graphene water spraying sheet and preparation method thereof

A technology of graphene and graphene powder, which is applied in the direction of chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of heat dissipation performance and strength optimization of water spray sheet, and the effect is not optimal, etc., to achieve Improve the heat dissipation effect, maintain the service life, and the effect of dense and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

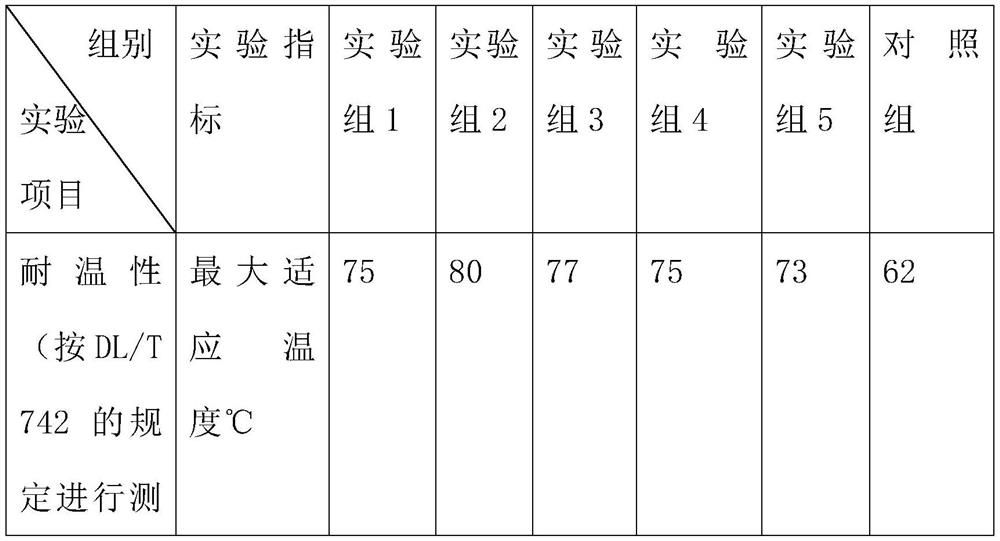

Examples

Embodiment 1

[0032] Weigh the following materials by weight: 78g of PVC resin, 10g of vermiculite, 33g of high-temperature activated bamboo charcoal powder, 40g of graphene powder, 31g of chlorinated polyvinyl chloride, 13g of tribasic lead sulfate, 2g of barium stearate, p-hydroxybenzoic acid 0.5 g of ether, 1 g of maleic anhydride, 7 g of polyethylene terephthalate, 5 g of polycarbonate, 11 g of toluene, and 7 g of diisobutyl phthalate.

[0033] Through the following steps: 1) Take the corresponding proportion of PVC resin, vermiculite, high-temperature activated bamboo charcoal powder, and graphene powder, mix them, carry out activation treatment at a high temperature of 1000 ° C, put them into the grinder, and vacuumize the grinder to obtain 500 mesh powder, for standby; 2) put the mixture obtained in step 1) into the drying device, and by controlling the temperature of the drying device, the drying temperature is slowly increased from 80°C to 130°C, and gradually after the temperature ...

Embodiment 2

[0035] Weigh the following materials by weight: PVC resin 88g, vermiculite 14g, high temperature activated bamboo charcoal powder 37g, graphene powder 50g, chlorinated polyvinyl chloride 35g, tribasic lead sulfate 15g, barium stearate 4g, p-hydroxybenzoic acid 2g of ether, 2g of maleic anhydride, 8g of polyethylene terephthalate, 6g of polycarbonate, 12g of distyrene, and 9g of diisobutyl phthalate.

[0036] Go through the following steps:

[0037]1) Take the corresponding proportion of PVC resin, vermiculite, high-temperature activated bamboo charcoal powder, and graphene powder, mix them, carry out activation treatment at a high temperature of 1100°C, put them into a grinder, and vacuumize the grinder to obtain 500-mesh powder, which is ready for use; 2) Put the mixture obtained in step 1) into the drying device, and control the temperature of the drying device so that the drying temperature rises slowly from 80°C to 130°C, and gradually decreases to 80°C after the temperatu...

Embodiment 3

[0039] Weigh the following materials by weight: PVC resin 98g, vermiculite 16g, high temperature activated bamboo charcoal powder 39g, graphene powder 60g, chlorinated polyvinyl chloride 41g, tribasic lead sulfate 17g, barium stearate 6g, p-hydroxybenzoic acid 2.5 g of ether, 3 g of maleic anhydride, 9 g of polyethylene terephthalate, 7 g of polycarbonate, 13 g of toluene, and 11 g of diisobutyl phthalate.

[0040] Through the following steps: 1) Take the corresponding proportion of PVC resin, vermiculite, high-temperature activated bamboo charcoal powder, and graphene powder, mix them, carry out activation treatment at a high temperature of 1200 ° C, put them into the grinder, and vacuumize the grinder to obtain 500 mesh powder, for standby; 2) put the mixture obtained in step 1) into the drying device, and by controlling the temperature of the drying device, the drying temperature is slowly increased from 80°C to 130°C, and gradually after the temperature reaches 130°C reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com