Method for preparing tire antioxidant 3100

An anti-aging agent and tire technology, which is applied in the preparation of organic compounds, amino compounds, chemical instruments and methods, etc., can solve the problems of restricting the process of industrialization, complex catalyst preparation process, and little significance of industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

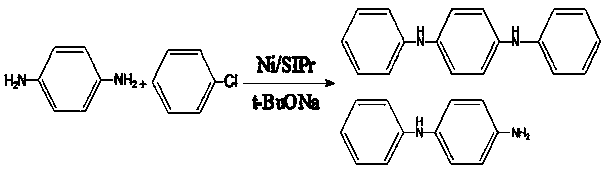

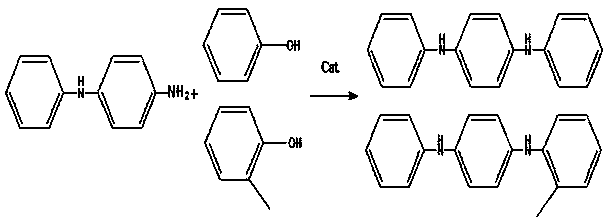

Problems solved by technology

Method used

Image

Examples

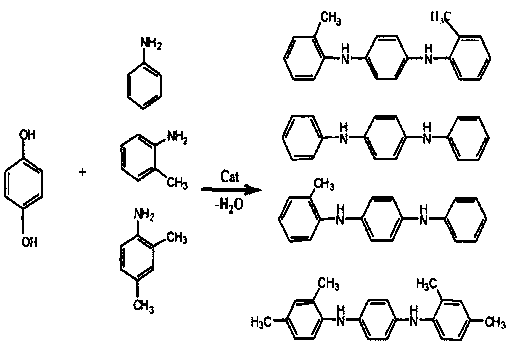

Embodiment 1

[0026] 184g p-aminodiphenylamine and 5.5g CuCl 2 Put it into the reactor, start stirring and mixing, raise the temperature to above 110°C, then turn on the vacuum to keep the vacuum degree at -0.06MPa, then add the mixture of 33g phenol and 72g o-cresol in 3 batches, and control the addition within 2h, Keeping the temperature within 110-140°C, the reaction is dehydrated, and when the temperature reaches 130°C and no water is released, the reaction is completed. The reaction solution was cooled to 90-100°C, and the catalyst was filtered off while hot to obtain 276 g of finished product, the reaction yield was 96.2%, and the melting point was 92.5°C.

Embodiment 2

[0028] 184g p-aminodiphenylamine and 6g CuCl 2 Put it into the reactor, start stirring and mixing, raise the temperature to above 110°C, then turn on the vacuum to keep the vacuum degree at -0.06MPa, then add the mixture of 47g phenol and 54g o-cresol in 5 batches, and control the addition within 2h, Keeping the temperature within 110-140°C, the reaction is dehydrated, and when the temperature reaches 130°C and no water is released, the reaction is completed. The reaction solution was cooled to 90-100°C, and the catalyst was filtered off while hot to obtain 280 g of finished product, the reaction yield was 98.2%, and the melting point was 92°C.

Embodiment 3

[0030] 184g p-aminodiphenylamine and 6g NiCl 2 Put it into the reactor, start stirring and mixing, raise the temperature to above 110 ℃, then turn on the vacuum to keep the vacuum degree at -0.06MPa, then add the mixture of 61g phenol and 38g o-cresol in 4 batches, and control the addition within 2h, Keeping the temperature within 110-140°C, the reaction is dehydrated, and when the temperature reaches 130°C and no water is released, the reaction is completed. The reaction solution was cooled to 90-100 DEG C, and the catalyst was filtered off while hot to obtain 270 g of finished product with a reaction yield of 95.7% and a melting point of 91.4 DEG C.

[0031] The finished products obtained in the above three cases were respectively tested by GC, and they were all tire anti-aging agent 3100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com