Treatment method of p-aminodiphenylamine production device wastewater

A technology of p-aminodiphenylamine and production equipment, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low COD content, high cost of sewage pretreatment, and recycling Formic acid process is cumbersome and other problems, to achieve the effect of high treatment load, short water retention time, reducing TOC and formic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

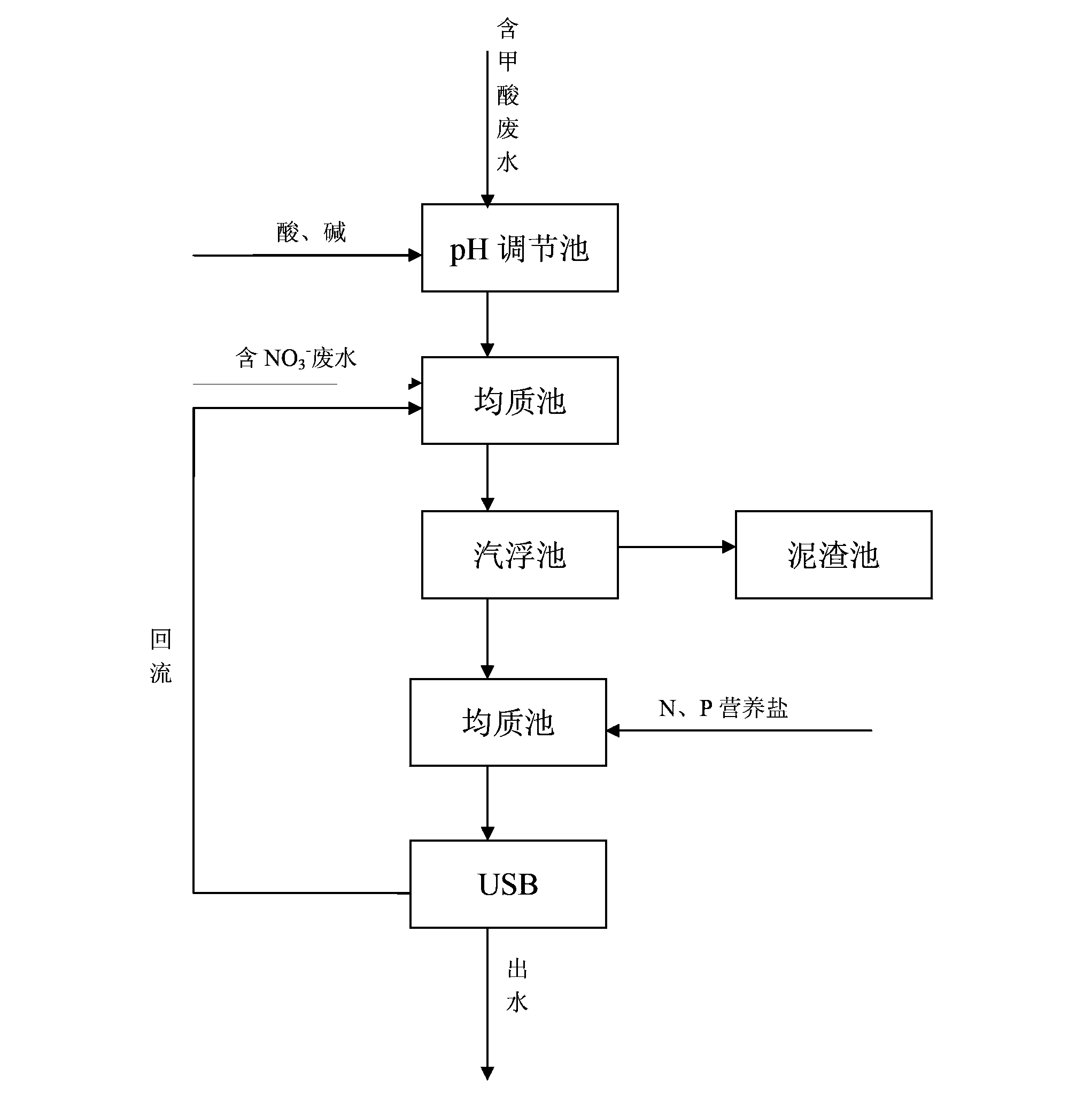

[0042] The waste water flow rate of a p-aminodiphenylamine production unit in a chemical plant is 100t / d, and the pollutant indicators before entering the process are: influent COD is 55000mg / L, TOC is 31920mg / L, formic acid concentration is 156950mg / L, and the waste water enters Add dilute HCl after the pH adjustment tank to adjust the pH of the influent to 4.50.

[0043] Then the wastewater flows into the homogeneous tank by itself, and contains NO 3 - The catalyst waste water was mixed, and a small amount of dilution water was added and part of the USB effluent from the return pump returned to the water inlet through the return pipe was diluted to 50 times for the waste water of the p-aminodiphenylamine production unit. The pH of the final mixed water was 6.50, NO 3 - The concentration is 948mg / L, and the C / N in the wastewater is maintained at about 2.98.

[0044] Then the wastewater enters the air flotation tank to further remove the flocculent suspended matter in the w...

Embodiment 2

[0050] The waste water flow rate of a p-aminodiphenylamine production unit in a chemical plant is 110t / d. The pollutant indicators before entering the process are: influent COD is 82000mg / L, TOC is 45195mg / L, formic acid concentration is 242750mg / L, and the waste water enters Add dilute HCl after the pH adjustment tank to adjust the pH of the influent to 6.00.

[0051] Then the wastewater flows into the homogeneous tank by itself, and contains NO 3 - The catalyst waste water was mixed, and a small amount of dilution water was added and part of the USB effluent from the reflux pump returned to the water inlet through the reflux pipe was diluted to 50 times for the waste water of the p-aminodiphenylamine production unit. The pH of the final mixed water was 9.00, NO 3 - The concentration is 2000.0mg / L, and the C / N in the wastewater is maintained at about 1.96.

[0052] Then the wastewater enters the air flotation tank to further remove the flocculent suspended matter in the wa...

Embodiment 3

[0058] The waste water flow rate of a p-aminodiphenylamine production unit in a chemical plant is 120t / d, and the pollutant indicators before entering the process are: influent COD is 48500mg / L, TOC is 30470mg / L, formic acid concentration is 144190mg / L, and the waste water enters Add dilute HCl after the pH adjustment tank to adjust the pH of the influent to 5.10.

[0059] Then the wastewater flows into the homogeneous tank by itself, and contains NO 3 - The catalyst wastewater was mixed, and a small amount of dilution water was added and part of the USB effluent from the reflux pump returned to the water inlet through the reflux pipe was diluted to 50 times for the wastewater of the p-aminodiphenylamine production unit. The pH of the final mixed water was 7.82, NO 3 - The concentration is 1061.3mg / L, and the C / N in the wastewater is maintained at about 2.54.

[0060] Then the wastewater enters the air flotation tank to further remove the flocculent suspended matter in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com