Mn, Co, Ce and Ti four-component NH3-SCR supported catalyst for low-temperature flue gas denitrification

A technology of NH3-SCR and low-temperature flue gas, which is applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, separation methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation and beneficial effects of the present invention are described below through specific examples, but the implementation scope of the present invention should not be construed in any way.

[0018] Evaluation method of catalyst activity:

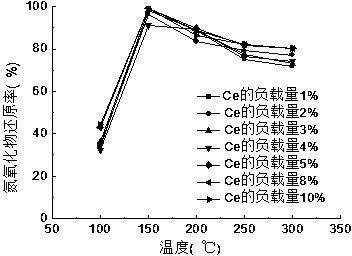

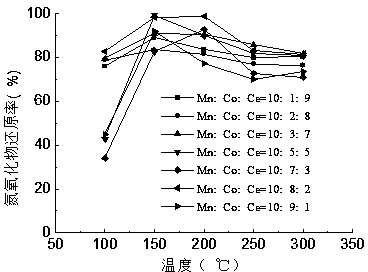

[0019] The catalytic activity of the prepared catalyst can be evaluated by the reduction conversion rate of NOx and the corresponding activation temperature. The calculation method of the reduction conversion rate is:

[0020] In the formula, is the concentration of nitrogen oxides at the inlet (mL / m3); is the concentration of nitrogen oxides at the outlet (mL / m3).

[0021] Detection method: Use a fixed-bed microreactor-nitrogen oxide analyzer detection system. The nitrogen oxide analyzer is the Australian EC9841 model, which uses chemiluminescence to detect NO and NO 2 , NOx.

[0022] Specific steps: put 5 mg of the weighed catalyst sample into the fixed bed reaction tube, and feed the reaction gas with the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com