Functionalized graphene oxide, preparation method and application thereof

A graphene and functionalization technology, applied in the field of functionalized graphene oxide and its preparation, can solve the problems of easy agglomeration, limited application, single function of graphene oxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

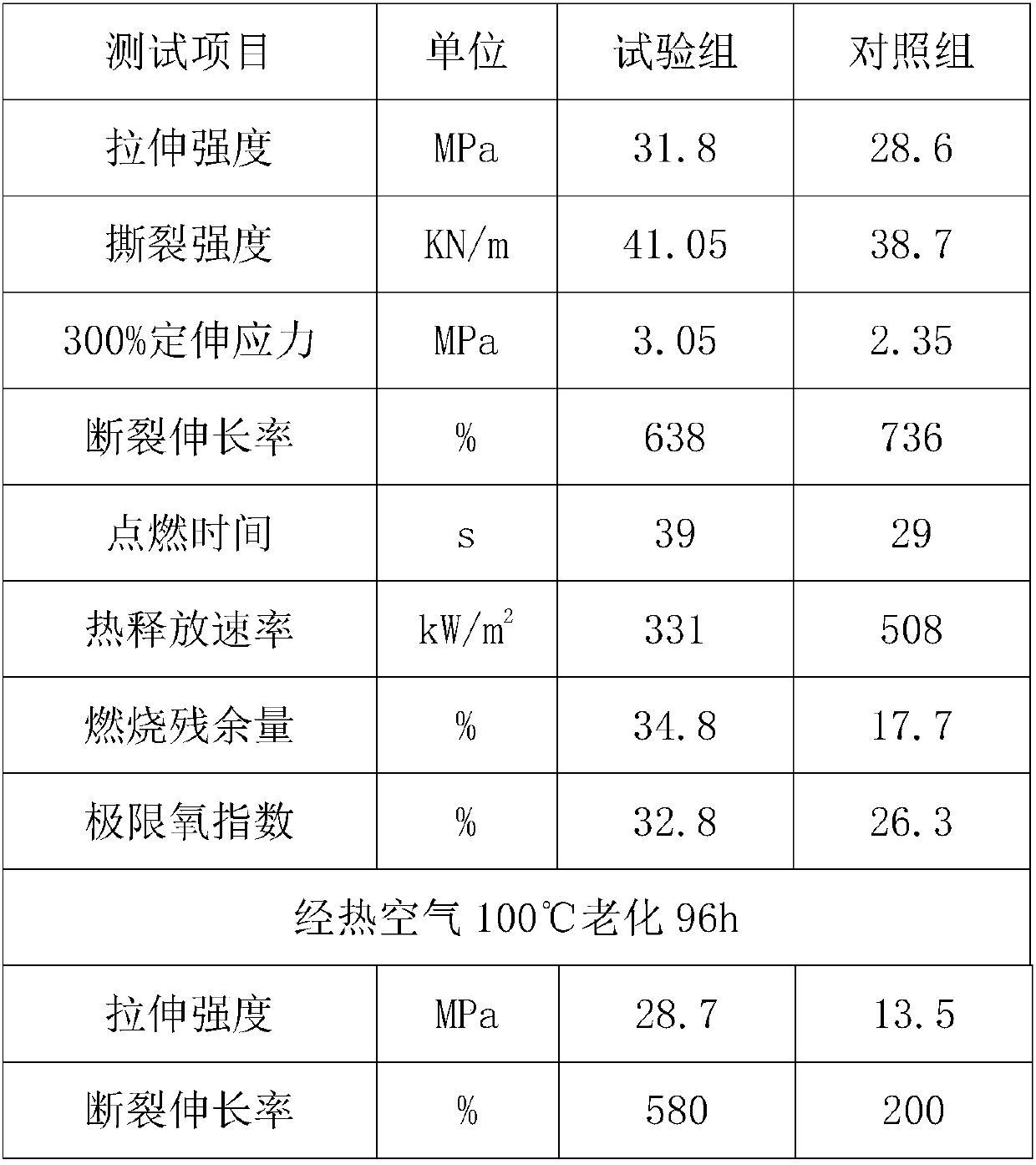

Examples

Embodiment 1

[0020] The method for preparing functionalized graphene oxide provided by the present invention includes the following steps:

[0021] S1. Under ice-water bath conditions, add cyanuric chloride to the mixture of acetone and water and stir evenly, add ammonia water, react at 5°C for 30 minutes, filter, wash, and dry after the reaction to obtain material A;

[0022] S2. Add material A to 1,4-dioxane and mix well, add the 1,4-dioxane solution of p-aminodiphenylamine and sodium carbonate, stir at room temperature for 30 minutes, filter, wash, and dry to obtain the material B;

[0023] S3. Add material B to 1,4-dioxane, add 1H,1H-perfluorooctylamine, adjust the pH to 7, heat up to 90°C, react for 3h, and leave it to stand, filter, and dry after the reaction is complete Get material C;

[0024] S4. The graphene oxide is acylated, and then added to dimethylformamide, and the material C is added and mixed uniformly, and the reaction is stirred at 90° C. for 20 hours. After the reaction, the ...

Embodiment 2

[0027] The method for preparing functionalized graphene oxide provided by the present invention includes the following steps:

[0028] S1. Under ice-water bath conditions, add cyanuric chloride to the mixture of acetone and water and stir evenly, add ammonia water, and react at 1°C for 50 minutes. After the reaction, filter, wash, and dry to obtain material A;

[0029] S2. Add material A to 1,4-dioxane and mix evenly, add the 1,4-dioxane solution of p-aminodiphenylamine and sodium carbonate, stir at room temperature for 100 minutes, filter, wash, and dry to obtain the material B;

[0030] S3. Add material B to 1,4-dioxane, add 1H,1H-perfluorooctylamine, adjust the pH to 7, raise the temperature to 80°C, react for 4h, and then stand, filter and dry after the reaction Get material C;

[0031] S4. The graphene oxide is acylated, and then added to dimethylformamide, and the material C is added and mixed uniformly, and the reaction is stirred at 80° C. for 30 hours. After the reaction, th...

Embodiment 3

[0034] The method for preparing functionalized graphene oxide provided by the present invention includes the following steps:

[0035] S1. Under ice-water bath conditions, add cyanuric chloride to the mixture of acetone and water and stir evenly, add ammonia water, react at 4°C for 38 minutes, filter, wash, and dry after the reaction to obtain material A;

[0036] S2. Add material A to 1,4-dioxane and mix evenly, add the 1,4-dioxane solution of p-aminodiphenylamine and sodium carbonate, stir at room temperature for 50 minutes, filter, wash, and dry to obtain the material B;

[0037] S3. Add material B to 1,4-dioxane, add 1H,1H-perfluorooctylamine, adjust the pH to 7, raise the temperature to 87°C, and react for 3.3h. After the reaction, let it stand and filter. Material C is obtained by drying;

[0038] S4, the graphene oxide is acylated, and then added to dimethylformamide, the material C is added and mixed uniformly, the reaction is stirred at 87°C for 24 hours, and the material D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com