Centrifugal sludge dewatering device based on ultrasonic

A sludge dehydration and centrifugal technology, which is applied in the direction of sludge detoxification, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of unfavorable miniaturization of sludge treatment, unfavorable environmental protection, and bulky equipment , to achieve the effect of facilitating subsequent processing and application, miniaturization and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

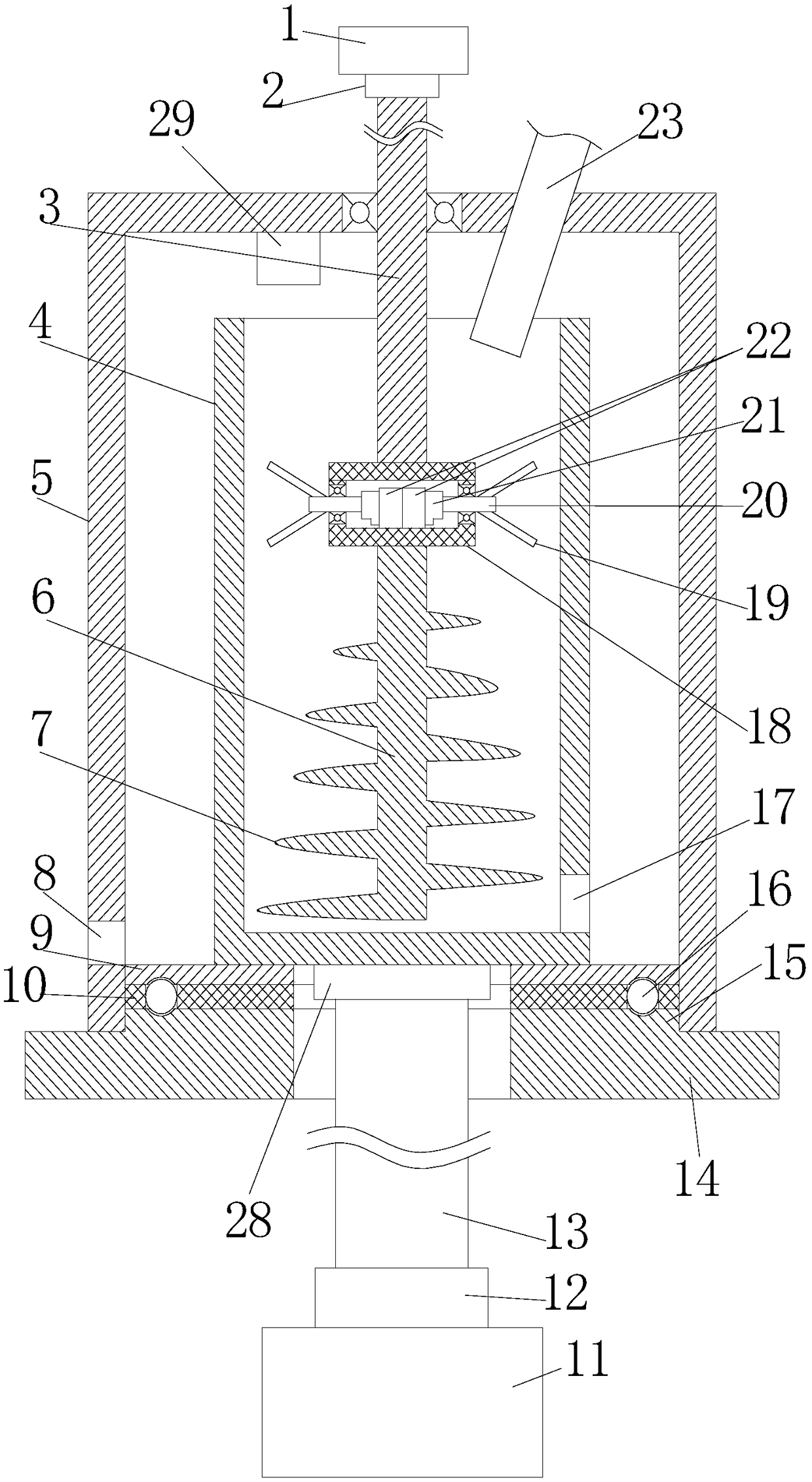

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail, as shown in the figure:

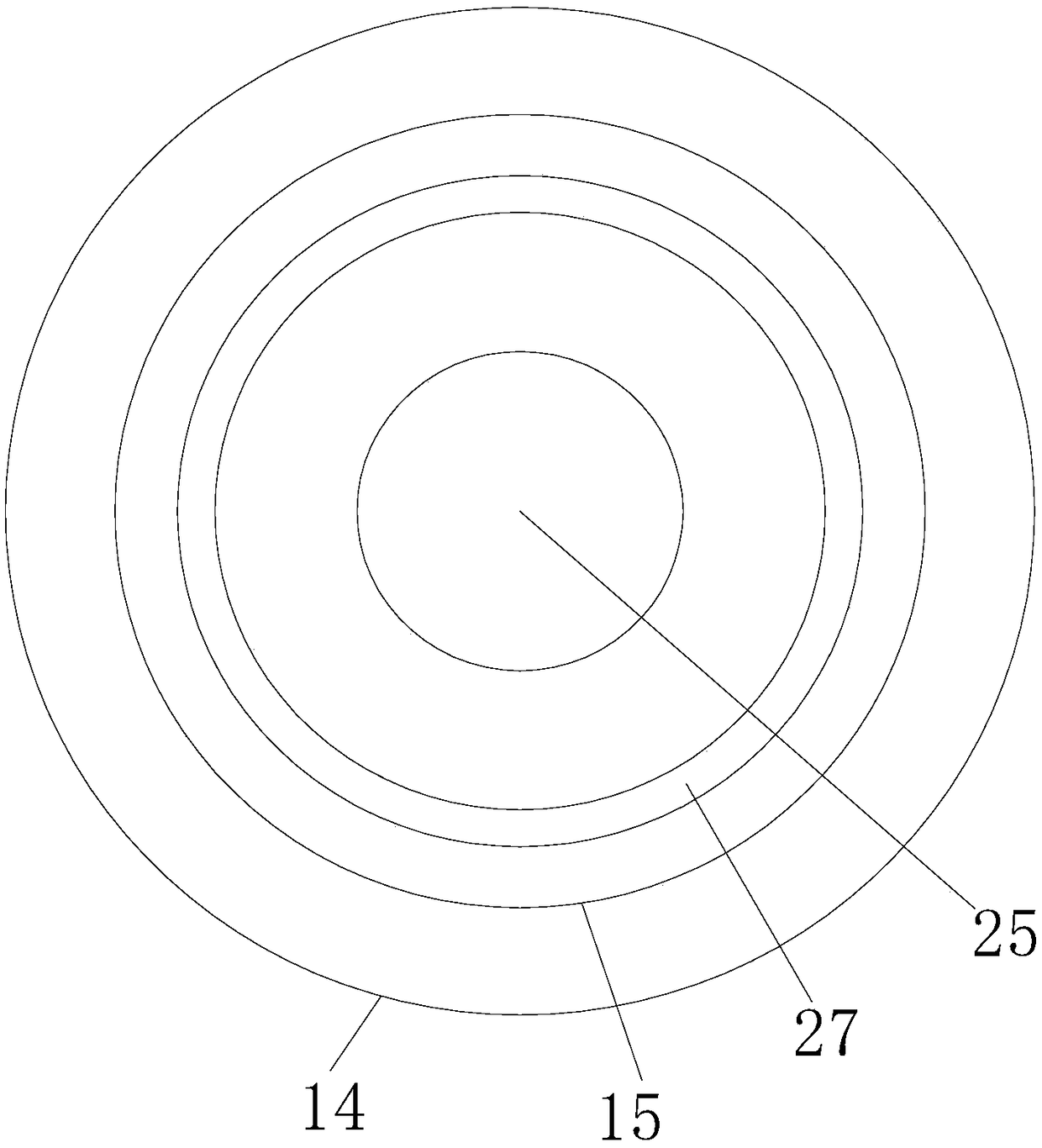

[0032] The purpose of the present invention is to provide a centrifugal sludge dewatering device, including a housing 5, a base 14, a centrifugal cylinder 4, a stirring mechanism, an ultrasonic generator 29, a first drive motor 1 and a second drive motor 11;

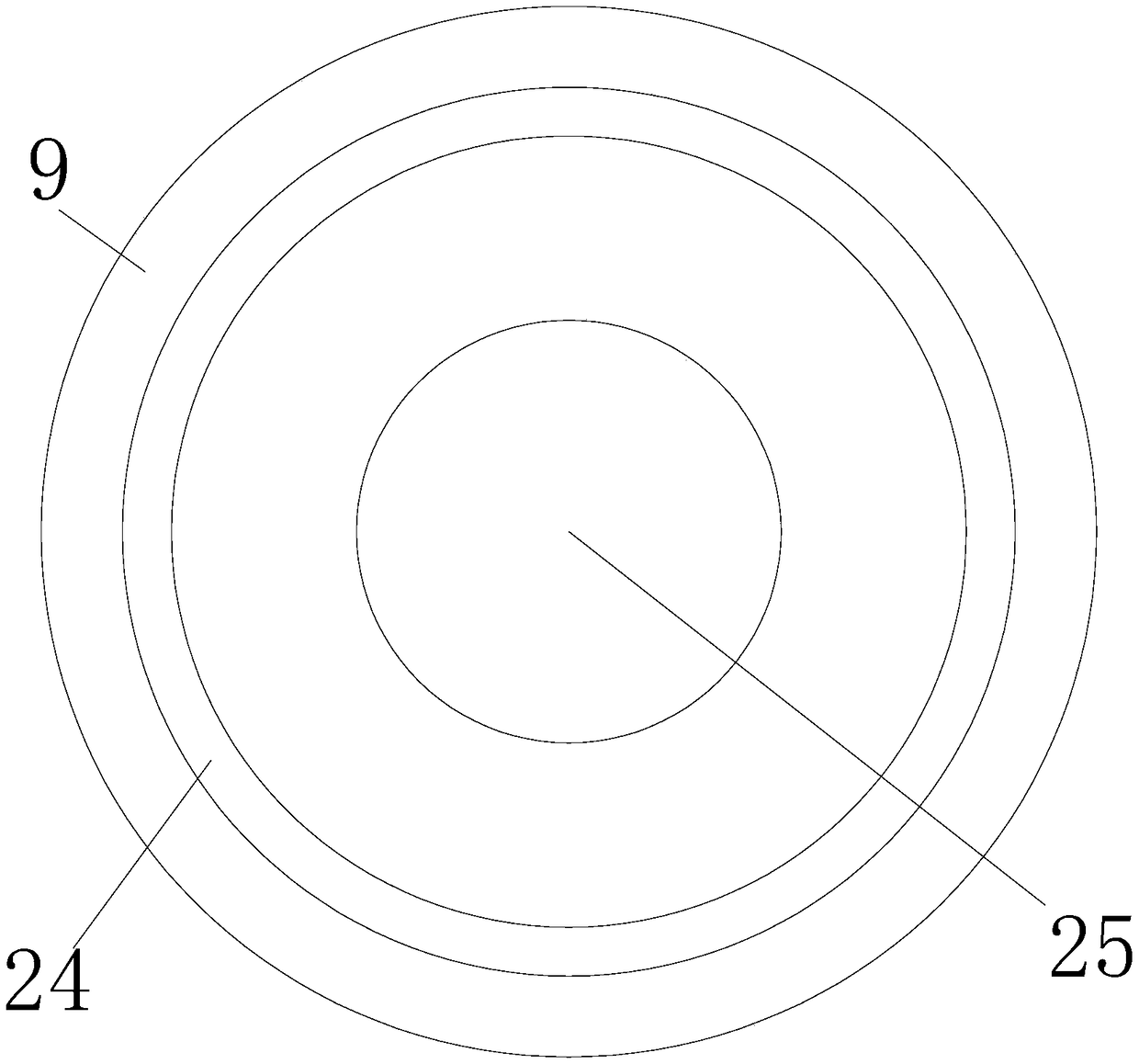

[0033] The shell 5 is a cylindrical structure and the shell 5 is turned upside down on the base 14 with the bottom facing upwards. The centrifugal cylinder 4 is coaxially arranged in the shell and the centrifugal cylinder 14 is fixedly arranged on the base 14 in a rotatable manner. , the second driving motor 11 drives the centrifugal cylinder 14 to rotate, the ultrasonic generator 29 is arranged on the inner side of the bottom of the casing 5 and the ultrasonic emission direction of the ultrasonic generator 29 is facing the mouth of the centrifugal cylinder 4;

[0034] The stirring mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com