A magnesium-aluminum-based layered double hydroxide/SBS composite modifier, modified asphalt and preparation method thereof

A technology of double hydroxide and compound modifier, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of low apparent density, influence on UV protection, and difficulty in uniform dispersion, so as to avoid Degradation effect, improve anti-ultraviolet aging ability, good effect of ultraviolet protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 59 parts (parts by mass, the same below) SBS, 30 parts of surface organically modified magnesium-aluminum-based layered double hydroxide, 0.2 parts of tetrasulfide bis(1,5-pentylene) thiuram and 10.8 parts of minus third-line oil Place in a high-speed mixer at 95℃ for blending for 15 minutes, then add the blend to a single-screw extruder for extruding and granulation. The die temperature is 170℃ to obtain magnesium-aluminum-based layered double hydroxide. / SBS compound modifier.

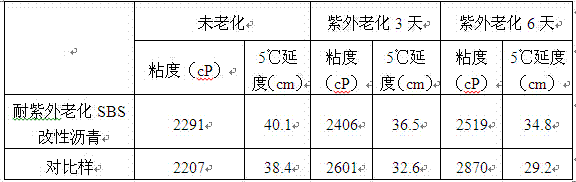

[0030] Heat 93.43 parts of road petroleum asphalt (with a penetration of 93dmm at 25°C and a softening point of 45.1°C) to 175°C, add it to a reaction tank with agitator and asphalt colloid mill, turn on the agitator, and add 6.5 parts while stirring The magnesium-aluminum-based layered double hydroxide / SBS composite modifier prepared above and 0.07 parts of sulfur, keep the reaction temperature at 175℃±5℃, stir for 5 minutes to make the magnesium-aluminum-based layered double hydroxide / SBS compo...

Embodiment 2

[0036] 53 parts of SBS, 32 parts of surface organically modified magnesium-aluminum-based layered double hydroxide, 0.4 parts of tetramethylthiuram disulfide and 14.6 parts of minus third line oil were blended in a high-speed mixer at a temperature of 95℃ for 15 minutes , And then add the blend into a single-screw extruder for extruding and granulation, and the temperature of the die is about 170°C to obtain the magnesium-aluminum-based layered double hydroxide / SBS composite modifier.

[0037] Heat 92 parts of road petroleum asphalt (with a penetration of 73dmm at 25°C and a softening point of 47.3°C) to 175°C, add it to a reaction tank with agitator and asphalt colloid mill, turn on the agitator, and add 7.9 parts while stirring The magnesium-aluminum-based layered double hydroxide / SBS composite modifier prepared above and 0.1 part of sulfur, keep the reaction temperature at 175℃±5℃, stir for 5 minutes to make the magnesium-aluminum-based layered double hydroxide / SBS composite mo...

Embodiment 3

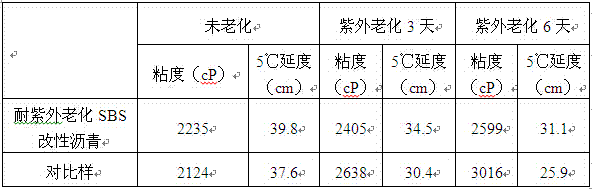

[0043] Put 51 parts of SBS, 35 parts of surface organically modified magnesium-aluminum-based layered double hydroxide, 0.3 parts of bis(1,5-pentylidene) thiuram tetrasulfide and 13.7 parts of minus third line oil at a temperature of 95℃ Blend in a high-speed mixer for 15 minutes, and then add the blend to a single-screw extruder for extruding and granulation. The temperature of the die is about 170°C to obtain the magnesium-aluminum-based layered double hydroxide / SBS composite modifier .

[0044] Heat 90.9 parts of road petroleum asphalt (with a penetration of 81dmm at 25°C and a softening point of 46.6°C) to 175°C, add it to a reaction tank with agitator and asphalt colloid mill, turn on the agitator, and add 8.98 parts while stirring The magnesium-aluminum-based layered double hydroxide / SBS composite modifier prepared above and 0.12 parts of sulfur, keep the reaction temperature at 175℃±5℃, stir for 5 minutes to make the magnesium-aluminum-based layered double hydroxide / SBS co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com