Degradable drainage board, material compound and preparation technology

A technology of material composition and drainage board, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of non-degradable, time-consuming and labor-consuming, polluting the environment, etc., achieve good environmental protection and energy saving, and simple and easy preparation process Easy to get the effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation process of a degradable drainage board, comprising the following steps:

[0028] S1. Mix the raw materials according to the ratio of 12 parts by mass of wheat straw, 15 parts of corn straw, 6 parts of bamboo fiber, 20 parts of pine fiber, 5 parts of coconut shell fiber, 10 parts of abaca fiber, and 4 parts of rice husk powder, obtain plant fibers;

[0029] S2. Mixing 75% plant fiber with 25% solid adhesive and stirring evenly, then heating to 120° C., and compressing it into a flat plate by pressing the plate 5 times with a plate pressing device;

[0030] S3. Grooving the flat plate in S2 through a molding die to obtain a degradable plate body;

[0031] S4. Coating a layer of degradable filter net on the surface of the degradable board body can obtain the degradable drainage board.

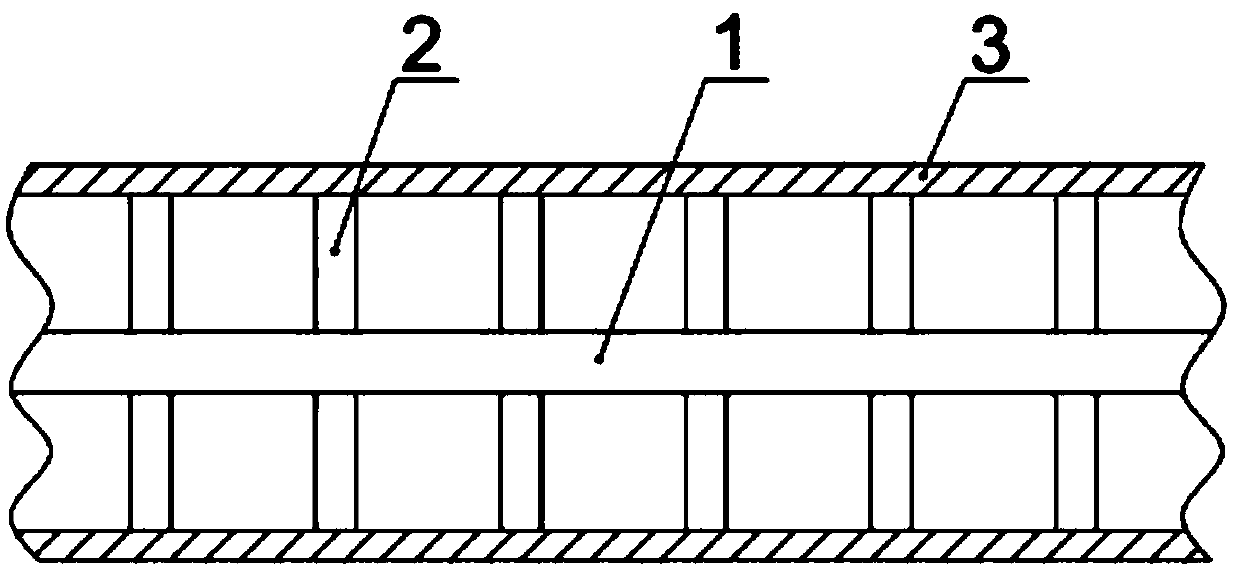

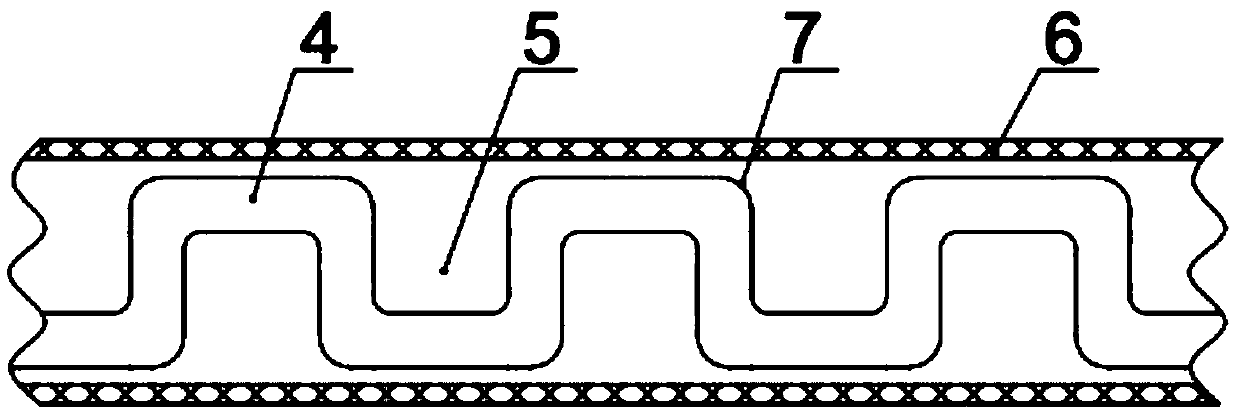

[0032] Such as figure 2 As shown, the obtained degradable drainage board includes a degradable board body, the surface of the degradable board body is covered with a layer...

Embodiment 2

[0034] A preparation process of a degradable drainage board, comprising the following steps:

[0035] S1. Mix the raw materials according to the ratio of 17 parts of wheat straw, 20 parts of corn straw, 11 parts of bamboo fiber, 25 parts of pine fiber, 13 parts of coconut shell fiber, 17 parts of abaca fiber and 12 parts of rice husk powder in parts by mass, obtain plant fibers;

[0036] S2. Mixing 65% plant fiber with 35% solid adhesive and stirring evenly, then heating to 180° C., and compressing it into a flat plate by pressing the plate three times with a plate pressing device;

[0037] S3. Grooving the flat plate in S2 through a molding die to obtain a degradable plate body;

[0038] S4. Coating a layer of degradable filter net on the surface of the degradable board body can obtain the degradable drainage board.

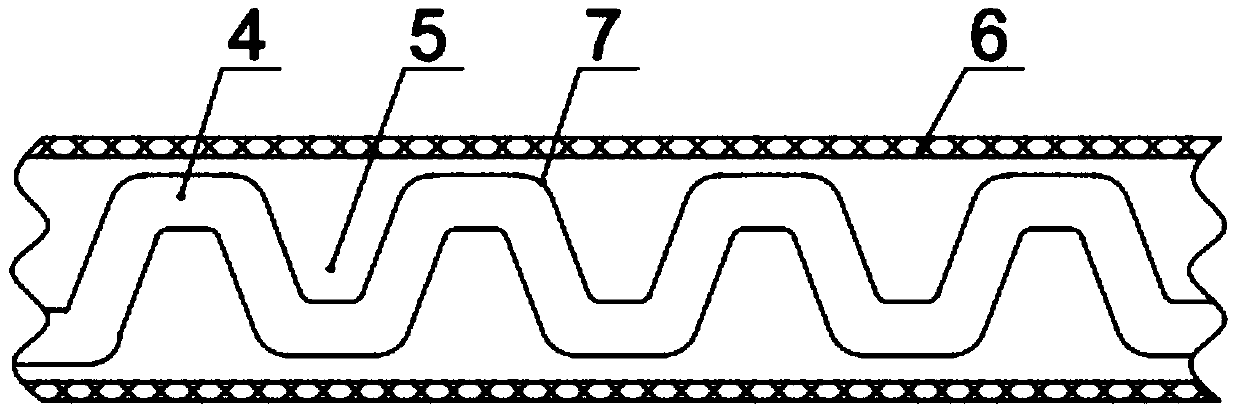

[0039] Such as image 3 As shown, the obtained degradable drainage board includes a degradable board body, the surface of the degradable board body is covere...

Embodiment 3

[0041] A preparation process of a degradable drainage board, comprising the following steps:

[0042] S1. Mix the raw materials according to the ratio of 15 parts of wheat straw, 17 parts of corn straw, 10 parts of bamboo fiber, 22 parts of pine fiber, 10 parts of coconut shell fiber, 15 parts of abaca fiber and 8 parts of rice husk powder in parts by mass, obtain plant fibers;

[0043] S2. Mixing 70% plant fiber with 30% solid adhesive and stirring evenly, then heating to 140° C., and compressing it into a flat plate through pressing plate 4 times with a pressing plate device;

[0044] S3. Grooving the flat plate in S2 through a molding die to obtain a degradable plate body;

[0045] S4. Coating a layer of degradable filter net on the surface of the degradable board body can obtain the degradable drainage board.

[0046] Such as figure 2 As shown, the obtained degradable drainage board includes a degradable board body, the surface of the degradable board body is covered w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com