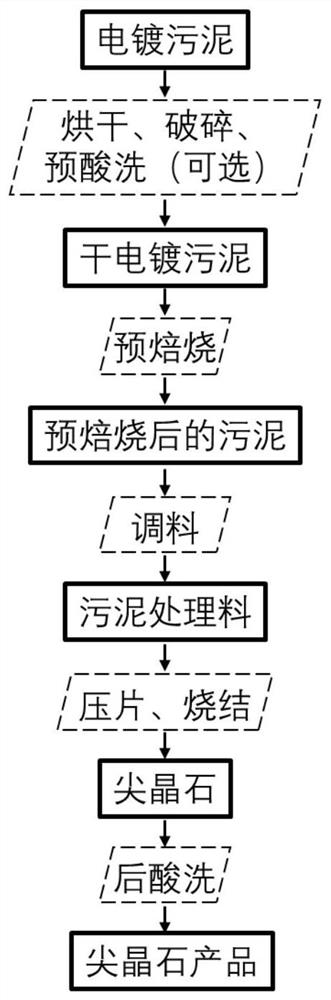

Method for preparing high-value spinel material by resourcefully treating electroplating sludge

A technology for electroplating sludge and spinel, which is applied in chemical instruments and methods, preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, chemical/physical processes, etc. Solve the problems such as the type of mud and heavy metals, and achieve the effect of increasing the yield, avoiding secondary pollution, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043](1) Take a certain electroplating sludge, dry it and crush it, and measure the content of its main elements as shown in Table 1:

[0044] Table 1 Types and contents of electroplating sludge elements

[0045] element Ni Al Ca S Fe Si content 27.1% 13.9% 6.0% 4.4% 3.7% 1.9%

[0046] It can be seen from Table 1 that the sludge is mainly composed of nickel and aluminum elements. After nickel is extracted by pre-aciding, MgO is added to prepare magnesium aluminum spinel. The specific method is:

[0047] Take 20g of the dried and crushed sludge, add 100mL of dilute hydrochloric acid to extract nickel, stir for 30min, and the extract solution has a balanced pH ≈ 4; then filter to obtain a nickel-containing solution and filter cake; dry the filter cake and break it;

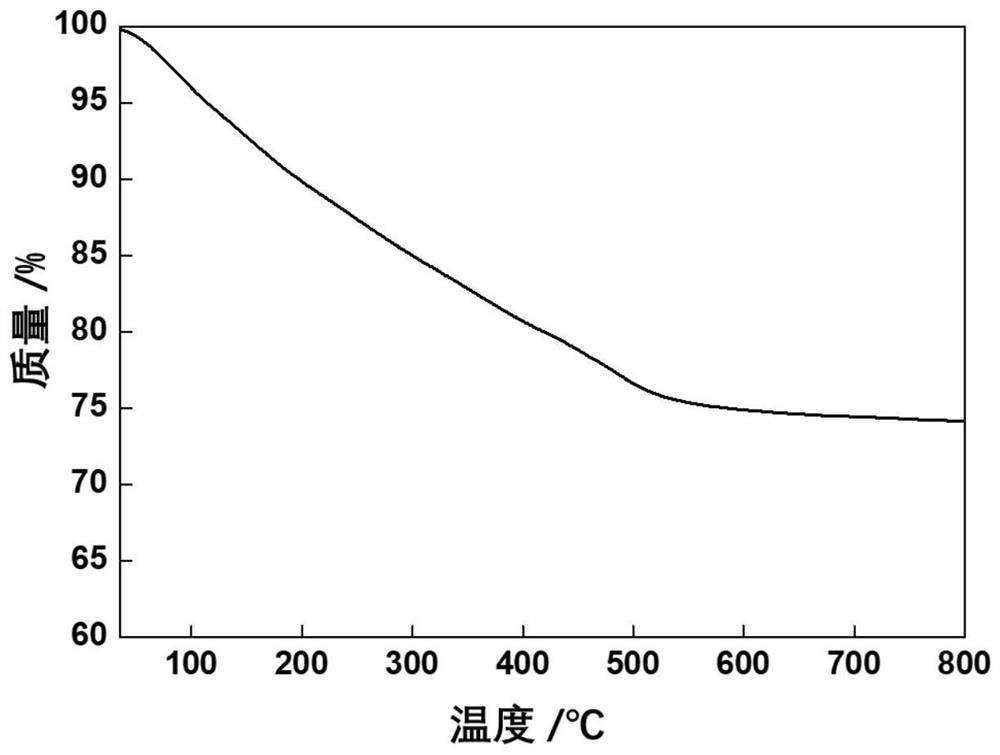

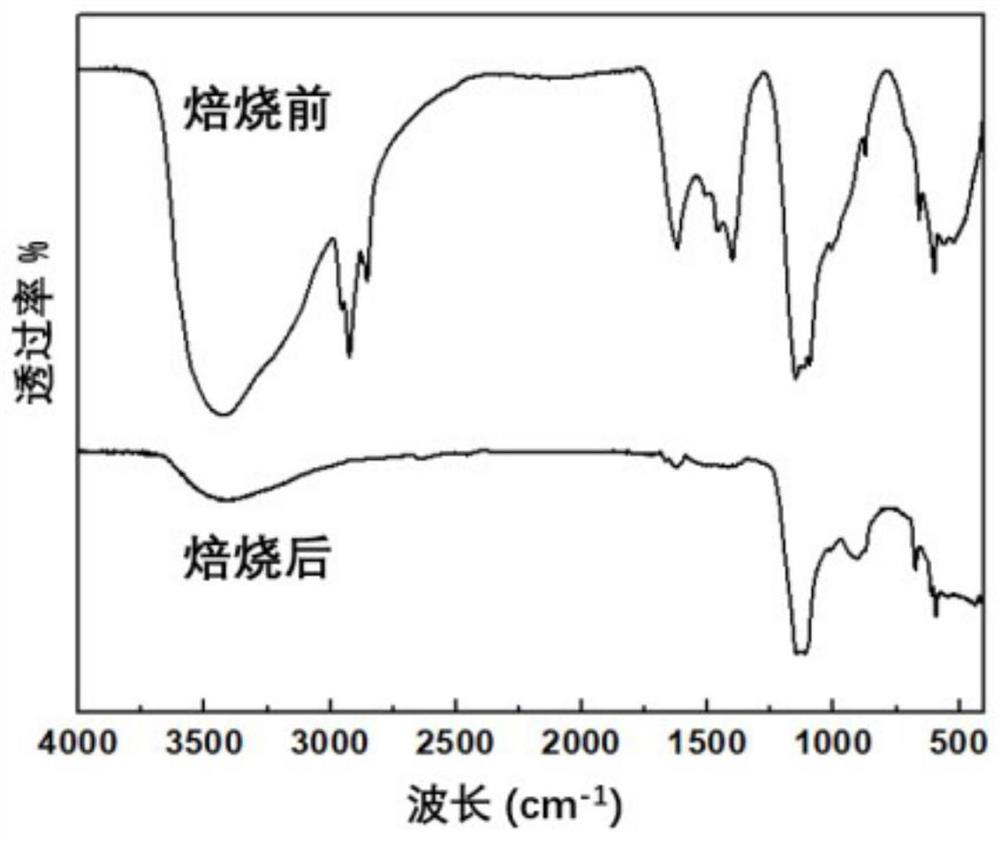

[0048] (2) pre-calcining the dried sludge after step (1) at 400° C. for 0.5 hours;

[0049] (3) The pre-roasted material is broken, the total mass is 12.8g, and the Ni content ...

Embodiment 2

[0053] (1) Take a certain electroplating sludge, dry it and crush it, and measure the content of its main elements as shown in Table 2:

[0054] Table 2 Types and contents of electroplating sludge elements

[0055] element Fe Zn Ca S Al Cu content 16.5% 13.6% 7.8% 3.4% 1.4% 1.3%

[0056] The sample is mainly composed of iron and zinc elements, which can be obtained by adding Fe 2 o 3 Or ZnO to prepare magnetic zinc-iron spinel catalytic materials;

[0057] (2) Take 10 g of dried sludge crushed in step (1), and pre-roast at 500° C. for 1 hour;

[0058] (3) The material after pre-roasting is crushed, the total mass is 8.9g, the calculated iron content is 18.5%, and the zinc content is 15.3%; according to Fe:Zn molar ratio 2:1 (ZnFe 2 o 4 spinel) adding 1.0g Fe 2 o 3 Mix evenly to obtain sludge treatment material;

[0059] (4) Grinding the sludge treatment material prepared in step (3), and pressing it into tablets at 10MPa for 2min;

...

Embodiment 3

[0069] (1) Take a certain electroplating sludge, dry it and crush it, and measure the content of its main elements as shown in Table 3:

[0070] Table 3 Types and contents of electroplating sludge elements

[0071] element Cr Al Cu Ca S Fe content 14.9% 7.2% 5.9% 6.3% 4.3% 3.0%

[0072] The sample is mainly composed of chromium and aluminum elements, and magnesium aluminum chromium spinel refractory materials can be prepared by adding MgO; among them, the pH of the sludge leachate is 9, and chromium is easily oxidized at high temperature under alkaline conditions, so pre-acidification is required Wash, the specific method is:

[0073] Take 30g of dried and crushed sludge, add 60mL of dilute hydrochloric acid, stir for 10min, and the pH of the solution after equilibrium is ≈ 6; then filter to obtain dilute acid solution and sludge filter cake; dry the filter cake and break it;

[0074] (2) pre-roasting the dried sludge after step (1) at 350° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com