Polymerization manufacturing technique and device for polyamide

A production process, polyamide technology, applied in the field of polyamide polymerization production process and equipment, can solve the problem of caprolactam monomer recovery that does not solve the problem of oligomer extraction, extraction system slices are oxidized, and there is no way to extract oligomers To avoid problems such as dehydration, to achieve the effect of fast dehydration, preventing oxidation and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

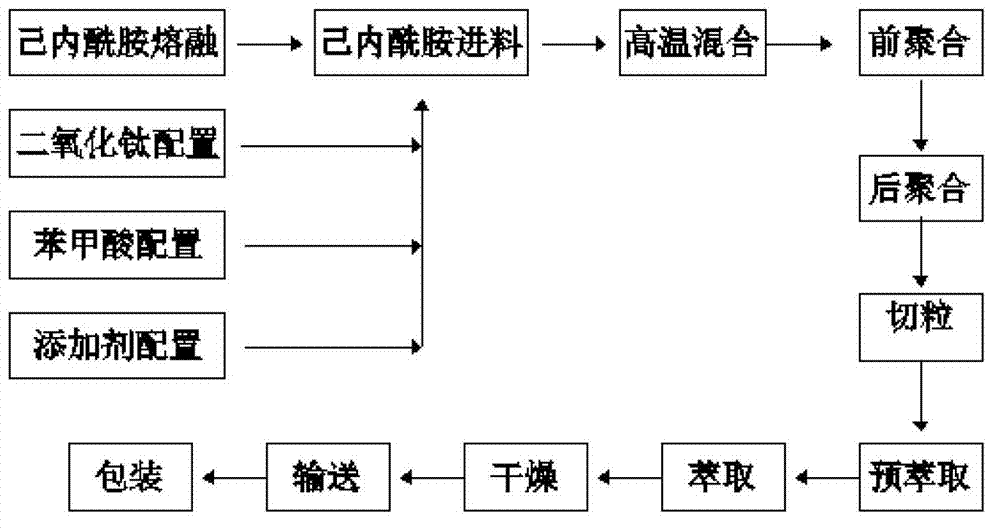

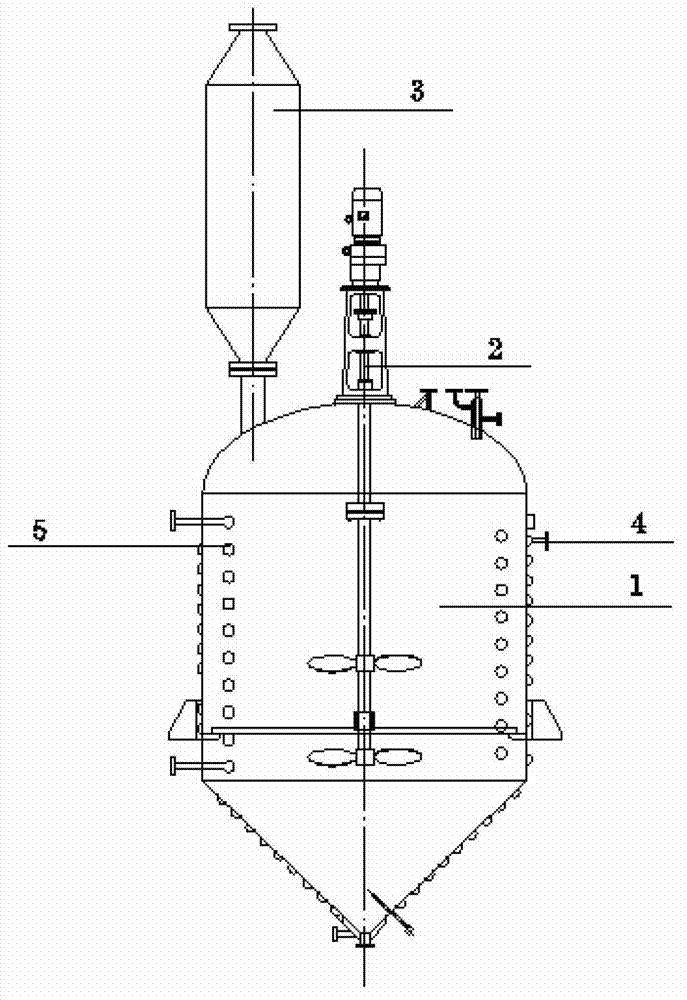

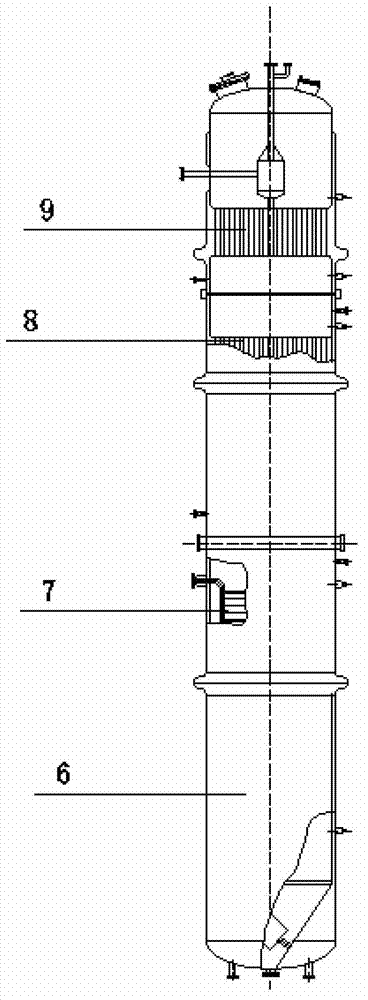

[0043] Example 1. Caprolactam is prepared with desalted water in the caprolactam melting system, and the preparation is melted under a nitrogen seal. The molten caprolactam enters the caprolactam feeding system and is prepared by a titanium dioxide preparation system. Its weight is caprolactam 2.0 ‰ of titanium dioxide, prepared by benzoic acid configurator, by weight of caprolactam 1.2‰ benzoic acid and 1.2‰ bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite filtered with standard fine filter, together Enter the caprolactam feeding system, send it into the high-temperature dynamic mixing tank, and carry out the polymerization of the front polymerization tower and the rear polymerization tower after high-temperature dynamic mixing, cut and pull, enter the pre-extraction tower from the feeding conduit 11, and extract the low Polymer, and then enter the extraction tower through the slice water separator 20 in the slice and water separator 19, extract the caprolactam monomer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com