Preparation method of water hyacinth biochar

A water hyacinth, biochar technology, applied in the fields of biofuels, separation methods, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

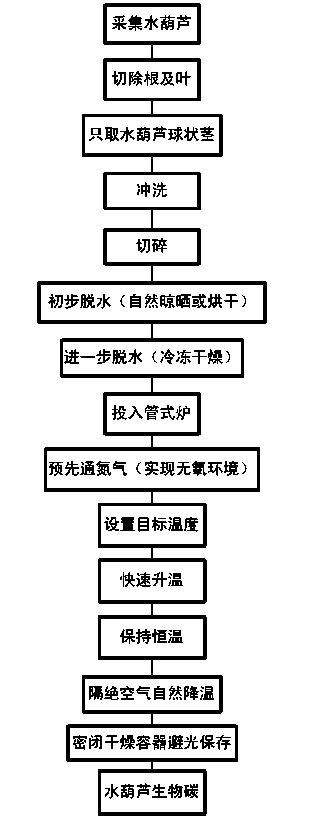

Image

Examples

Embodiment 1

[0023] Cut off the roots and leaves of the water hyacinth, and only take the expanded part of the petiole (the bulb); clean the surface impurities with clean water (tap water); chop the bulb of the water hyacinth to a degree of 0.6cm. Dry it naturally for 8 days in a well-lit place until the moisture content reaches 12.1%. After preliminary dehydration, the raw materials are placed in a freeze dryer for 6 hours; until the moisture content is 1.5%. Put the freeze-dried raw material into the tube furnace, and pass it into the furnace for 25 minutes before heating with a gas velocity of 300cm 3 / min of nitrogen to exhaust the air in the furnace. Set the reaction temperature to 600°C, and reach the target temperature in 15 minutes; keep the constant temperature for 60 minutes (adjust the temperature control element to make the temperature ±1°C). After the constant temperature pyrolysis is completed, turn off the power, keep the closed state of the reaction furnace, isolate the a...

Embodiment 2

[0027] Cut off the roots and leaves of the water hyacinth, take the stem (the whole stem), rinse with water; chop to 1cm, and let it dry naturally in the sun for 6 days until the water content reaches 14.8%. Put the raw material after preliminary dehydration into the tube furnace, and pass it into the furnace for 20 minutes before heating with a gas velocity of 250cm 3 / min of nitrogen, so that the reaction furnace is an oxygen-free environment. Set the reaction temperature to 450°C, rapidly increase the temperature (8 minutes to reach the target temperature), and then set the constant temperature reaction time to 40 minutes. After the constant temperature pyrolysis is completed, turn off the power, keep the reaction furnace closed, and cool down naturally to obtain water hyacinth biochar. (Remove after cooling to room temperature). The product number is BCL450.

[0028] Compared with BCH600, BCL450 has a lower cost and can be used as a soil improver; it can also be used as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com