Garbage cracking catalytic gasification furnace

A pyrolysis catalysis and pyrolysis gasification technology, which is applied in the field of waste pyrolysis catalytic gasifier, can solve the problems of long processing time, large pipelines, blockage, etc., and achieves the effects of compact structure, reduced manufacturing cost, and significant energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

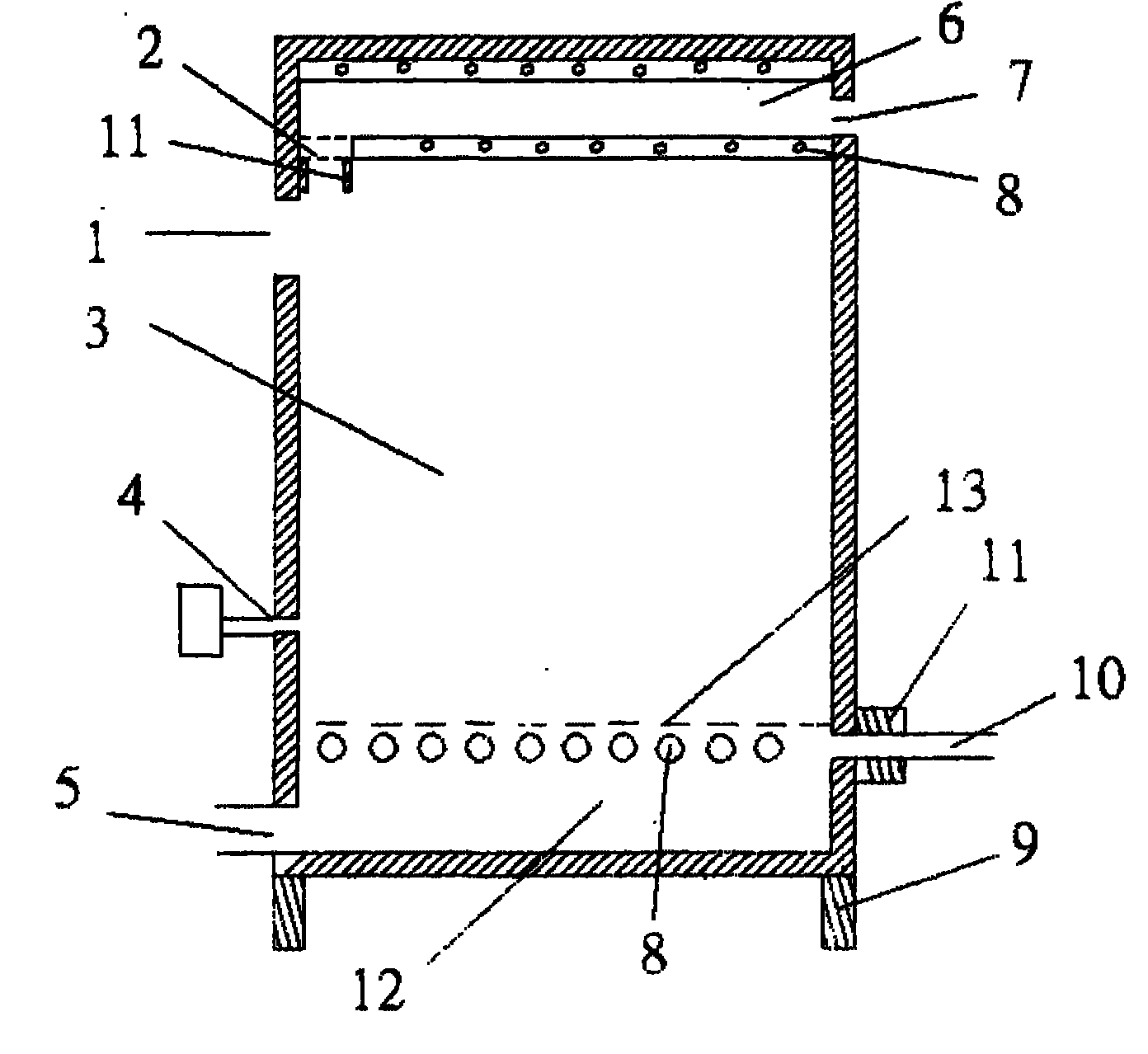

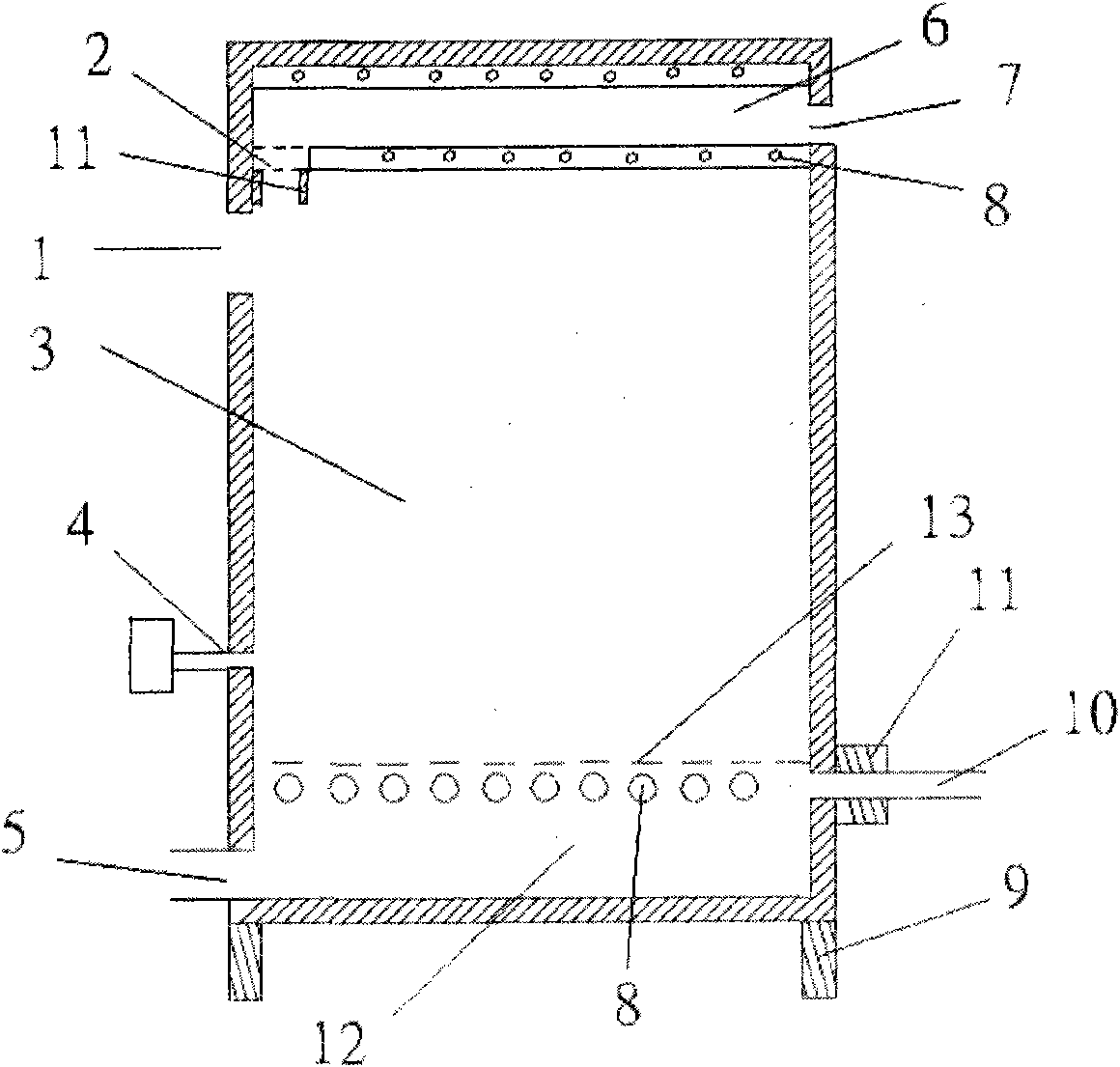

[0014] As shown in FIG. 1 , the garbage cracking catalytic gasification furnace is composed of a preheating chamber 12 , a cracking gasification chamber 3 and a catalytic reforming chamber 6 . The preheating chamber 12 is provided with an air inlet 10, an ash outlet 5, a grate 13 and an electric heating pipe 8, the air inlet 10 is connected with the air inlet pipe, the air inlet pipe is provided with a magnetizer 11, and the air passage in the magnetizer 11 is surrounded by A strong magnetic field magnet is set, and the same poles of the magnets are arranged opposite to each other; the cracking gasification chamber 3 is provided with a feeding port 1 and a water vapor inlet 4; the catalytic reforming chamber 6 is provided with a gas inlet 2, a product gas outlet 6 and an electric heating tube 8, and the gas A magnetizer 11 is provided at the entrance 2, and an appropriate amount of catalyst is placed in the catalytic reforming chamber 6.

[0015] Working process of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com