Vehicle-mounted oxy-hydrogen generation device

A generation device, hydrogen and oxygen technology, applied in the field of electrolysis, to achieve the effects of saving energy, reducing heat loss, and reducing heat discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

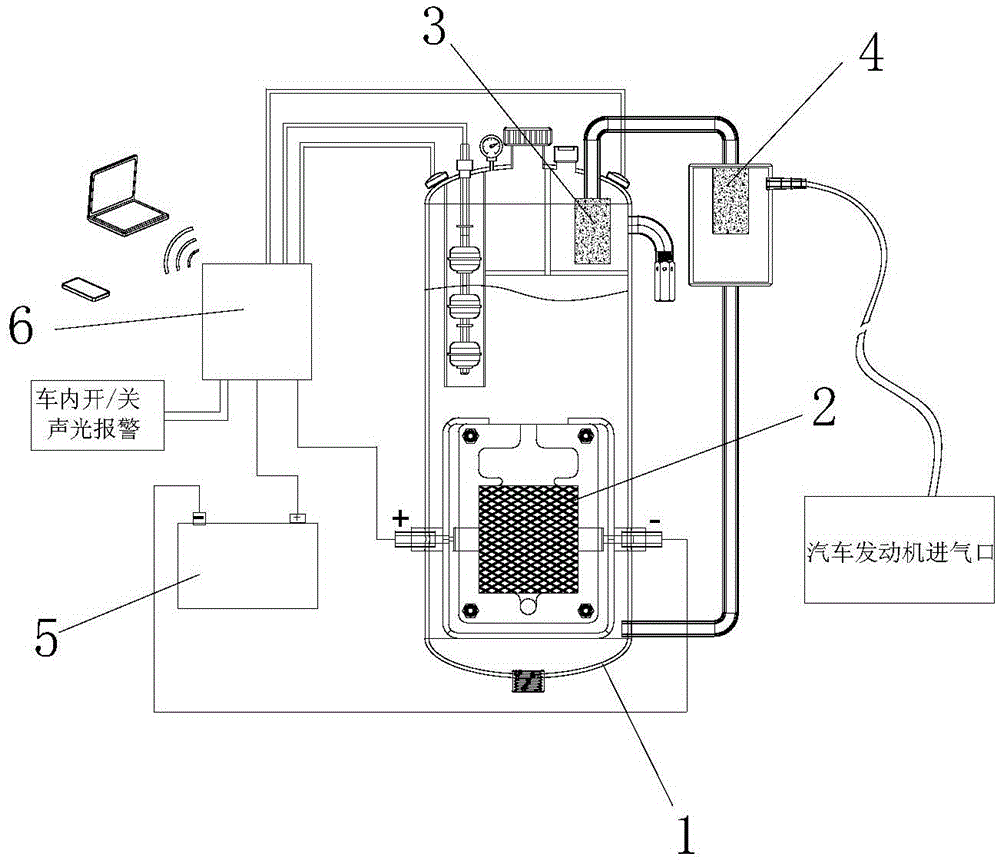

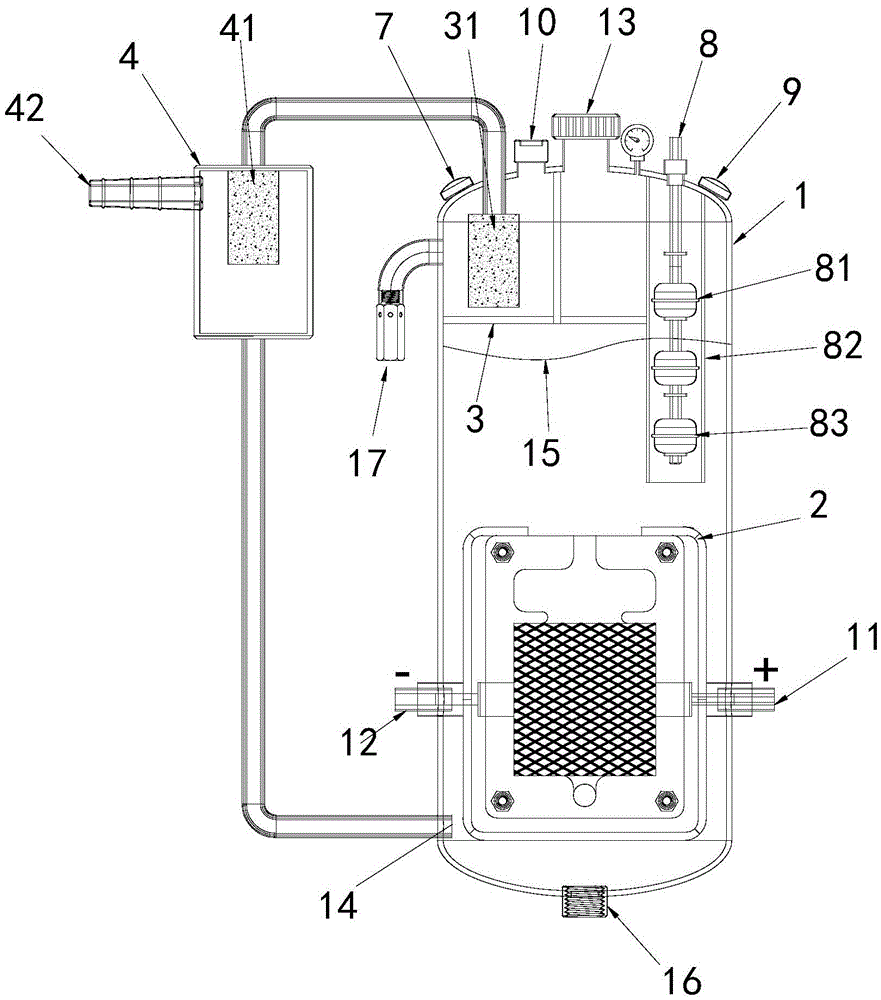

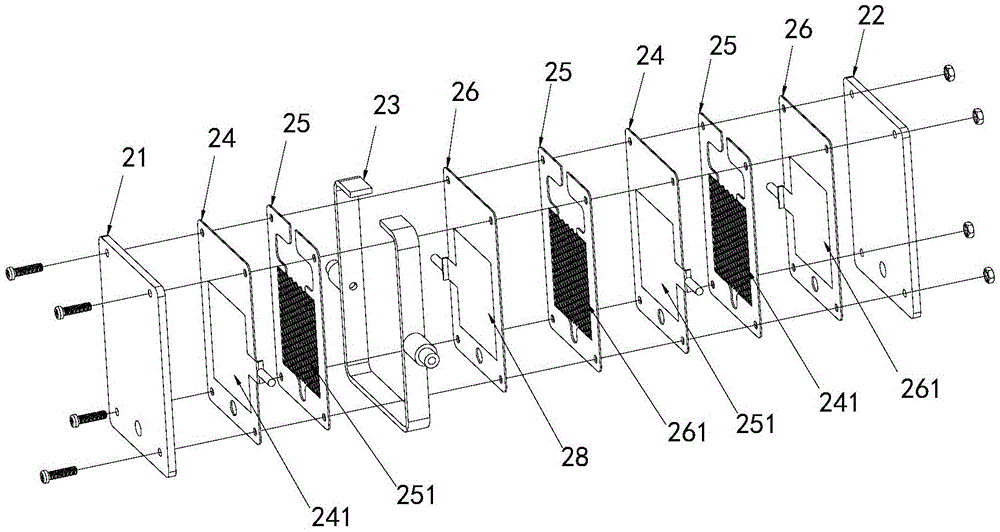

Embodiment 1

[0055] Design a set of vehicle-mounted hydrogen and oxygen generator, operating voltage 12-13.5V, current 20A, tank voltage 2V, electrolyzer gas production 80-150 liters / H, matching with 2.0 engine, the generator is installed in the interior space of the engine compartment of the car , use the electric energy of the car generator, use the cooling fan at the front of the engine to dissipate heat, and use the hydrogen and oxygen gas generated by the electrolysis of pure water for the engine to perform mixed catalytic combustion. Take a Honda car with a displacement of 2.0 in 2003 as an example. The ratio of the amount of oxygen mixture added to the displacement is about 1 / 1000, and the ratio of the amount of hydrogen-oxygen mixture added to the displacement is about 0.5 / 1000 during normal operation (engine speed 2000-3000 rpm). Under certain conditions, the fuel consumption drops from 13 liters / 100 kilometers to less than 10 liters / 100 kilometers, which can save 15-30% of fuel an...

Embodiment 2

[0057] Designed a set of vehicle-mounted hydrogen-oxygen generators for diesel engines. When the operating voltage is 20-30V and the current is 30-50A, the gas production of the electrolyzer is 300-450 liters / H. It is installed on the bus and tested with an exhaust gas analyzer. The NOx content of the vehicle exhaust in the following three states is as follows when the engine is idling and accelerating. The test results show that the NOx emission of the mixed hydrogen and oxygen is far better than the current SCR technology. Through April 2015 to the present, the actual In use, it is found that in addition to reducing the emission of NOx particles, the increase in fuel economy and power is particularly obvious during daily driving. The results are shown in Table 1.

[0058] Table 1

[0059] PM particles idle speed accelerate direct exhaust Nox 284ppm 134ppm Add SCR device to exhaust exhaust Nox 215ppm 109ppm Add hydrogen-oxygen mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com