Method for pretreating surplus sludge by using extracellular polymer lyase

An extracellular polymer and excess sludge technology, applied in biological sludge treatment, dewatering/drying/concentrating sludge treatment, etc., can solve problems such as increasing treatment costs, reduce treatment costs, reduce the use of enzymes, The effect of improving digestive performance and dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

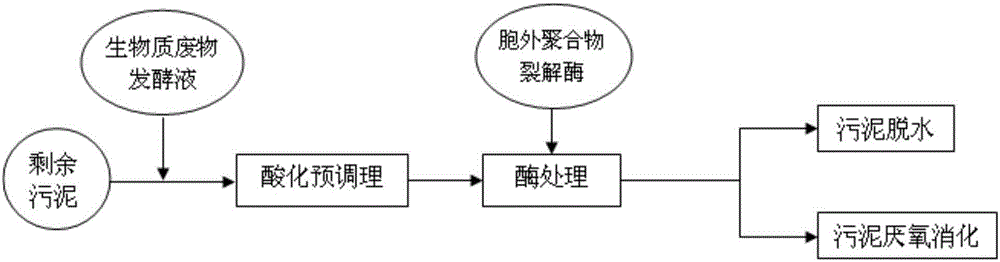

[0030] use as figure 1The process shown performs residual sludge pretreatment, including the following steps:

[0031] (1) Take 100mL of activated excess sludge (water content 90%) from the domestic sewage treatment plant, put it in a 500mL beaker, and adjust the pH of the excess sludge with catering waste fermentation liquid (containing acetic acid 8000mg / L, butyric acid 1500mg / L) It is 4.0, and then stand for 1hr. Next, 0.416 g of polygalacturonase powder with an activity of 1 U / mg was added under the action of magnetic stirring, and continuous cultivation was carried out in a constant temperature incubator at 35° C. for 5 hours.

[0032] (2) Take the sludge cultivated in step (1) and carry out centrifugal dehydration treatment, the centrifugation condition is 2000g, 10min.

[0033] By adopting the above-mentioned method, after 5 hours of enzymatic hydrolysis treatment, the capillary water absorption time (CST) of the sludge is reduced by 57%, the specific resistance (SRF)...

Embodiment 2

[0035] use as figure 1 The process shown performs residual sludge pretreatment, including the following steps:

[0036] (1) Take 100mL of residual sludge from domestic garbage sewage treatment plant (moisture content is 88%, organic matter accounts for 68% of dry basis, polysaccharide content accounts for 6.6% of dry basis, protein content accounts for 37% of dry basis), placed in In a 500mL beaker, adjust the pH to 5.0 with the remaining sludge fermentation broth (containing 3000mg / L acetic acid, 500mg / L propionic acid, and 400mg / L butyric acid), and let stand for 2h. Then, under the action of magnetic stirring, 0.416 g of polygalacturonase powder with an activity of 2.5 U / mg was added, and continuous cultivation was carried out in a constant temperature incubator at 55° C. for 4.5 hours.

[0037] (2) Take the sludge cultivated in step (1) and perform anaerobic digestion at 55° C. for 30 days.

[0038] Using the above-mentioned treatment method, before the sludge is treated...

Embodiment 3

[0040] use figure 1 The process shown, using extracellular polymeric lyase to carry out residual sludge pretreatment, includes the following steps:

[0041] (1) Acidification preconditioning of excess sludge: adjust the pH of the excess sludge to 4.0 with the fermented liquid generated after sludge hydrolysis and acidification, and then let it stand for 1 hr;

[0042] (2) Enzyme pretreatment: Add extracellular polymer lyase powder directly to the remaining sludge adjusted by pH in step (1), and the amount of extracellular polymer lyase powder added is 31.5U / kg dry sludge , mix evenly, and react for 5 hours at 20°C.

[0043] (3) Treatment of sludge after enzyme pretreatment: the sludge after step (2) enzyme pretreatment directly enters the dehydration process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com