Method for producing propylene and coproducing ethylene from C4 olefins

A technology of carbon tetraolefins and low-carbon olefins, which is applied in the field of olefin disproportionation and olefin catalytic cracking coupling process to produce propylene and by-product ethylene, so as to achieve the effect of improving conversion rate and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The experimental olefin disproportionation catalyst is a tungsten-based / molybdenum-based magnesium-modified composite catalyst. Among them, the carrier SiO 2 The specific surface area is 395.3m 2 / g, the pore volume is 0.87cm 3 g -1 , the pore size is 8.66nm, the acid content is 0.41mmolNH 3 g -1 ; The active component is supported by the equal volume impregnation method, and the active component WO in the catalyst 3 The mass content is 8%, MoO 3 The mass content is 5%, and the magnesium oxide content is 6%.

[0071] Phosphorous modified ZSM-5 molecular sieve is selected as the catalyst for olefin cracking, which is the combination of ZSM-5 molecular sieve and SiO 2 、Al 2 o 3 After mechanical mixing, adding binder, pressing into tablets and roasting, and then modifying the molded catalyst with phosphorus by an equal volume impregnation method to prepare it, wherein the phosphorus content is 2%. The phosphorus modified ZSM-5 molecular sieve has a specific surfa...

Embodiment 2

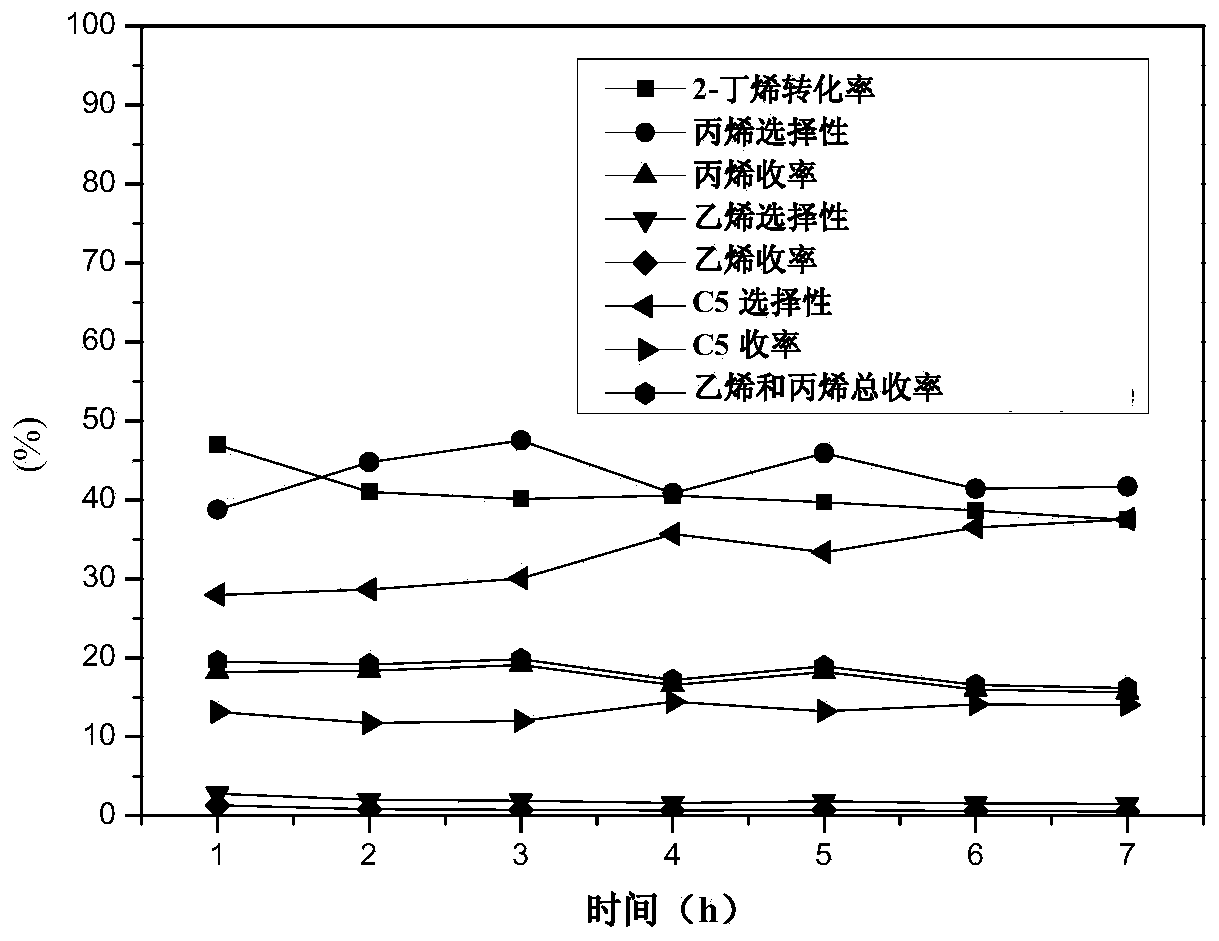

[0076] Compared with the process of Example 1, the present embodiment differs in that the C4-olefin raw material is passed into the light olefin disproportionation reaction device with a volume flow rate of 5ml / h, and the cracking reaction temperature in the olefin catalytic cracking device is controlled to be 500°C. Other processing conditions are with embodiment 1. Gas chromatography analysis of reaction products. For analysis results, see Image 6 .

Embodiment 3

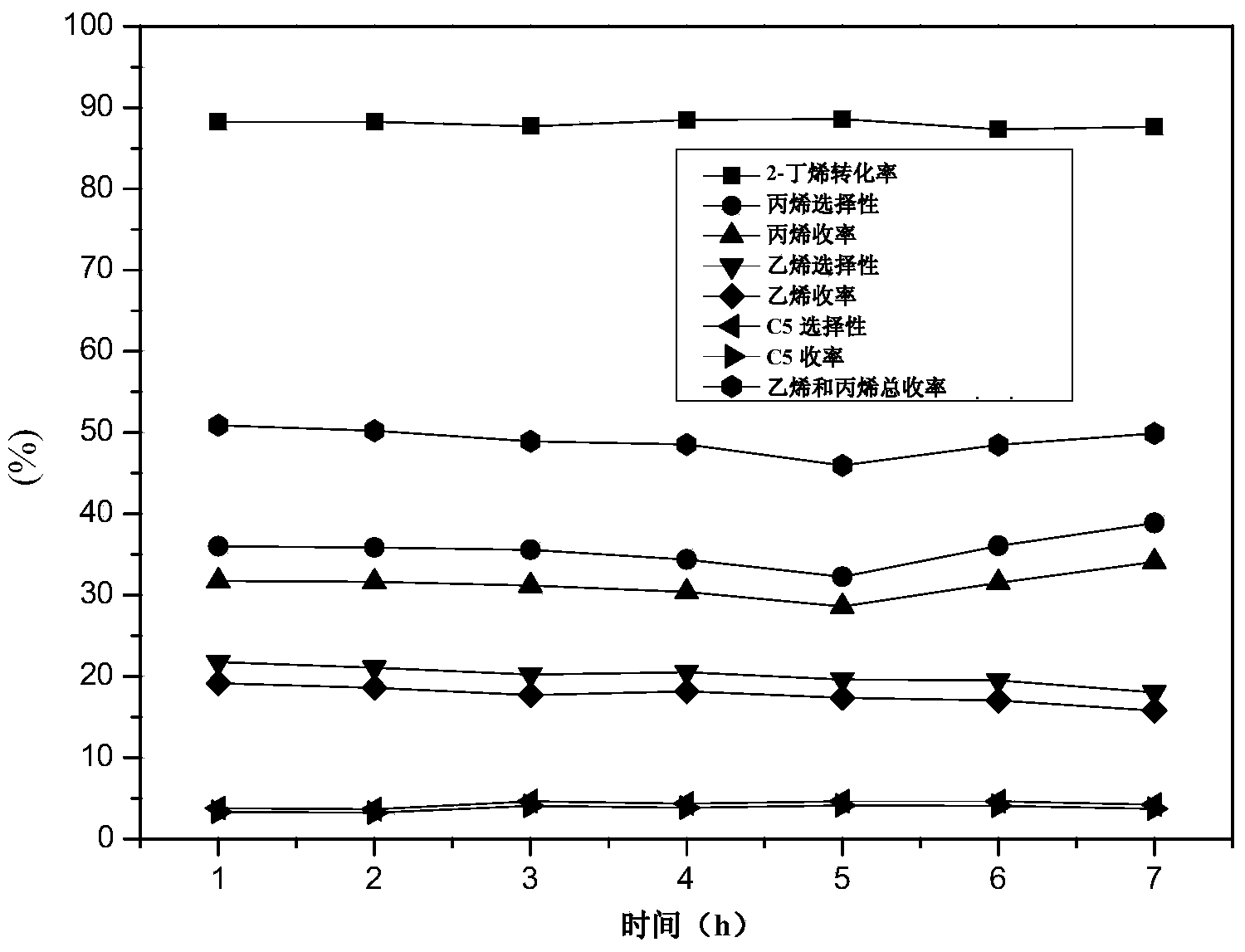

[0078] Compared with the process of Example 1, the present embodiment differs in that the carbon tetraolefin raw material is passed into the light olefin disproportionation reaction device with a volume flow rate of 5ml / h, and the disproportionation and cracking reaction catalyst filling ratio is 3:2, and Control the disproportionation reaction temperature of low-carbon olefins to 320°C, and the weight hourly space velocity to 6h -1 , the reaction pressure is 0.6MPa; all the other process conditions are the same as in Example 1. Gas chromatography analysis of reaction products. For analysis results, see Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com