Electrochemical liquefaction method and device for biomass taking ionic liquid and supercritical CO2 as media

An ionic liquid and liquefaction device technology, applied in the field of biomass regeneration and energy utilization, can solve the problems of unformed system and weakened hydrogen bonding, and achieve the effects of improving electrical conductivity, promoting biomass cracking, and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: with [Bmim]Cl-supercritical CO 2 As the medium, the porous plate-shaped Fe-Mo alloy hydrogen evolution electrode is the reactor cathode, the carbon fiber electrode is the anode, and the Al 2 o 3 The preparation method of pine wood liquefaction bio-oil as catalyst is as follows:

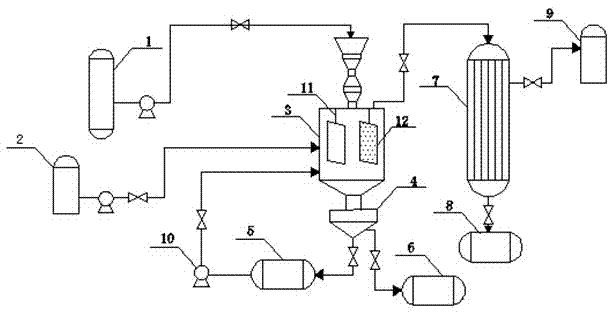

[0027] Such as figure 1 As shown, the device used in this embodiment includes mixer 1, CO 2 Gas tank 2, cracking reactor 3, solid-liquid separator 4, ionic liquid storage tank 5, solid collector 6, condenser 7, liquid collector 8, gas collector 9, transfer pump 10, mixer 1 through cracking reaction Device 3 is connected with condenser 7, and condenser 7 is connected with liquid collector 8, gas collector 9 respectively, and cracking reactor 3 bottom is connected with solid-liquid separator 4, and solid-liquid separator 4 is conveyed through ionic liquid storage tank 5 The pump 10 is connected, and the transfer pump 10 is connected to the cracking reactor 3 to form a loop, and ...

Embodiment 2

[0030] Embodiment 2: with [Amim]Br-supercritical CO 2 Tobacco leaf liquefied bio-oil was prepared as the medium, the plate-shaped activated carbon electrode as the reactor cathode, the mesh titanium electrode as the anode, and NaCl as the catalyst:

[0031] The structure of the device used in this embodiment is the same as in Embodiment 1;

[0032] Mix 23kg of dried tobacco leaf powder with a particle size of 35 mesh and 1.15kg of catalyst NaCl in the mixer, unscrew the valve after stirring evenly, put the mixture into the cracking reactor, and then add 345L of water and 57.5kg of ionic liquid [Amim] Br, close the valve, the CO 2 Pass it into the pyrolysis reactor, seal it and raise the temperature to 180°C, increase the pressure to 11MPa, and feed the anode of the reactor with an AC voltage of 45V. When the pyrolysis of biomass begins to produce gas and overpressure, the automatic exhaust valve will automatically exhaust the constant pressure. This state is maintained for 0...

Embodiment 3

[0033] Example 3: With [Emim]OTf-supercritical CO 2 As the medium, the porous plate-shaped Pt-Ce alloy hydrogen evolution electrode is the reactor cathode, the rod-shaped aluminum electrode is the anode, and the NiCl 3 The corn stover liquefied bio-oil as catalyst was prepared as follows:

[0034] The structure of the device used in this embodiment is the same as in Embodiment 1;

[0035] 18kg of dried corn stalk powder with a particle size of 48 mesh and 0.9kg of catalyst NiCl 3 Mix in the mixer, unscrew the valve after stirring evenly, put the mixture into the cracking reactor, then add 270L water and 54kg ionic liquid [EMIM]OTf, close the valve; 2 Pass it into the pyrolysis reactor, seal it and raise the temperature to 210°C, increase the pressure to 9.5MPa, and pass an AC voltage of 0.8V to the cathode and anode of the reactor, and the automatic exhaust valve will automatically exhaust when the biomass pyrolysis starts to produce gas and overpressure Constant pressure, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com